Polish printer wins praise for vodka label

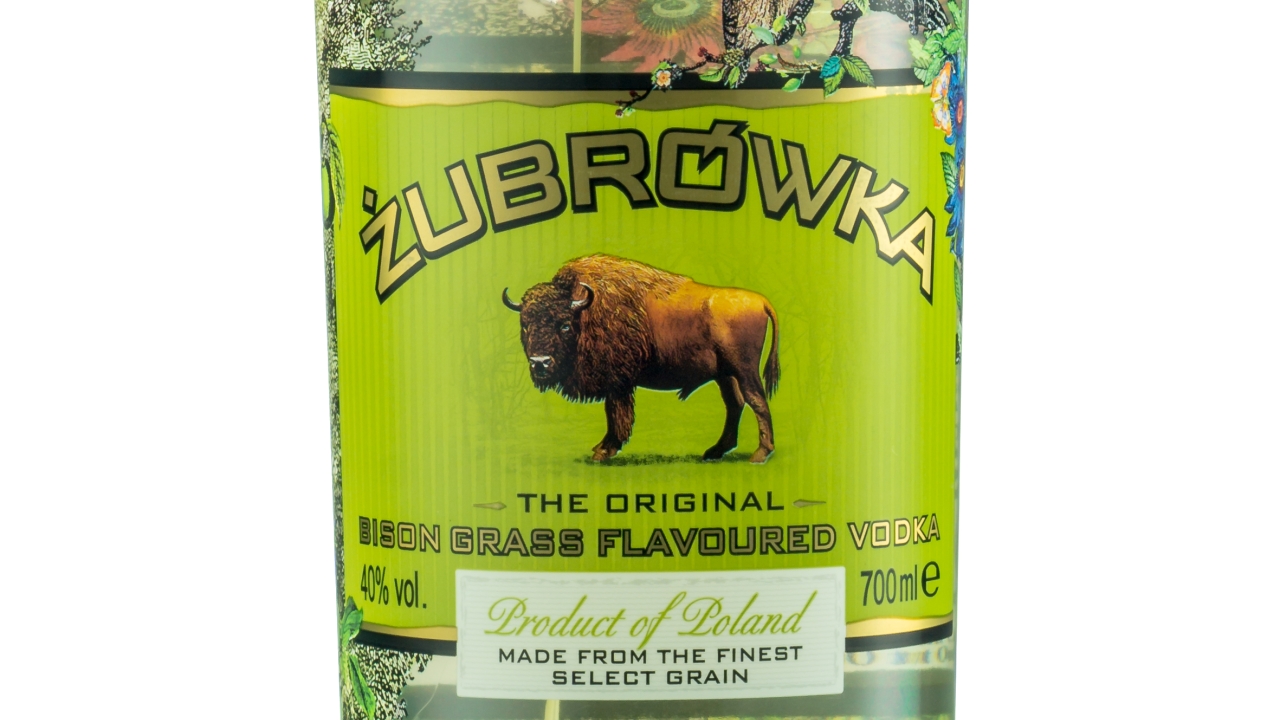

Polish printer Masterpress was named amongst the finalists at the recent World Beverage Innovation Awards 2014 for a shrink sleeve label it produced for the French-language issue of Żubrówka Special Edition vodka.

Masterpress, based in Bialystok, Poland, is the country’s largest shrink sleeve producer, and one of the leading print converters with over 16 years of experience in printing and producing various types of packaging. It utilizes flexo, offset, gravure and digital print processes. Masterpress also sells shrink sleeve label machinery.

The shrink sleeve label entered into the awards program by Masterpress was the only Polish product to be included in the finalists of the World Beverage Innovation Awards 2014, which were presented at BrauBeviale, an exhibition for the whole beverage production supply chain. It took place November 11-13 in Nuremberg, Germany.

2014 was the 11th edition of the World Beverage Innovation Awards, with a total of 325 entries from 40 countries received this year, competing 26 different categories, from Best Juice or Juice Drink to Best New Beverage Concept, as well as categories for brands, ingredients, packaging, design, manufacturing and processing, sustainability, and marketing and communications.

The Żubrówka Special Edition shrink sleeve was named as a finalist in the Best Packaging Design or Label category, and was selected from a field of 28 as one of five finalists in the category. Coffebrewerby Grower's Cup was the winning entry.

Waldemar Zdrodowski, vice-president at Masterpress, said: ‘The shrink sleeve label decorating the Żubrówka Special Edition vodka emphasizes the brand's premium feel. It was printed on a clear PET film through an innovative hybrid printing process which made it possible to achieve vibrant colors with flexo UV inks, while at the same time gravure capabilities allowed us to achieve the metallic gold finish. The entire process took place in-line, within a single press.

‘We have also applied a matte varnish, which softened some of the label’s artwork elements. Additionally, we used a solution that eliminated spots which could appear on the unprinted surface of the label due to condensation.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.