Expanded gamut printing 101

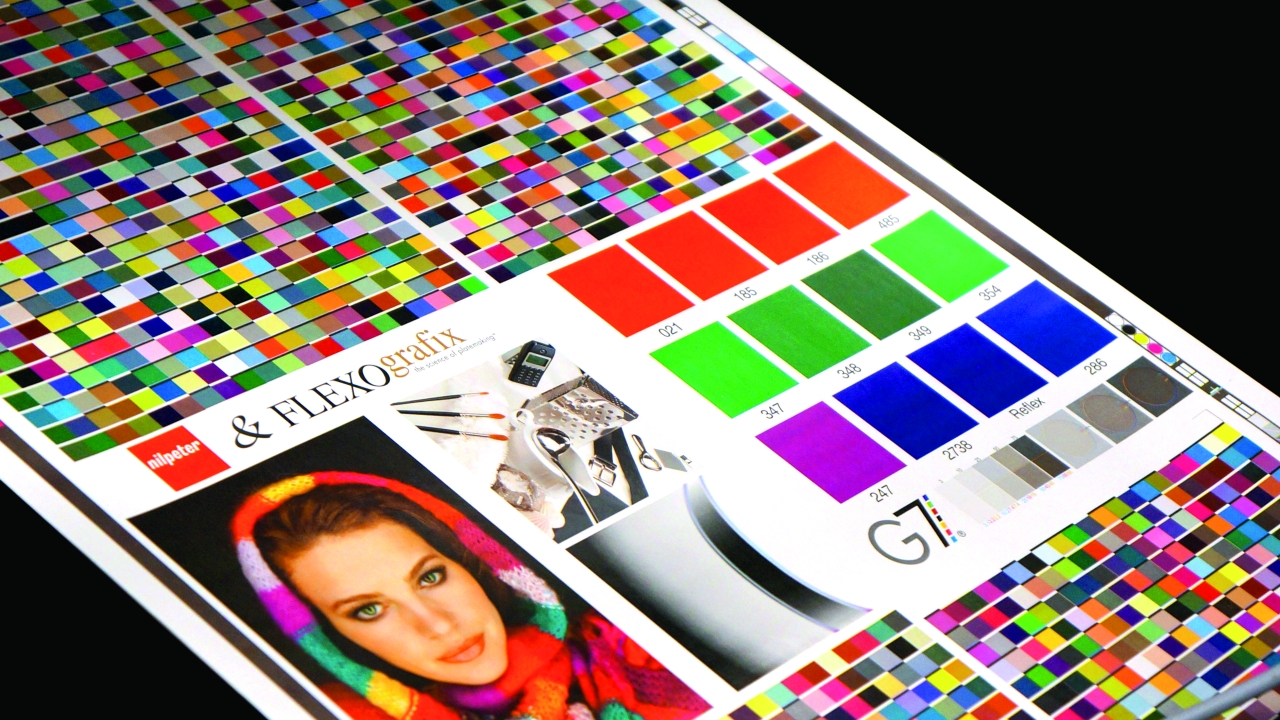

So what is Expanded Gamut Printing? Basically, it’s seven color process printing: Cyan, Magenta, Yellow, Black with the addition of Orange, Green and Violet. It’s also referred to as Extended Gamut, Hi-Fi Printing and Fixed Pallet Ink Set. For this article we’ll use Expanded Gamut or EG Printing. The scope of this article will try to answer a few of the common questions that are asked by companies considering whether or not they should be doing EG printing. A few of the questions are: Why do it? What’s needed to do it? How to do it?

It’s been said that EG seems to point to the quality aspects of the process while Fixed Pallet Ink Set points to the economic aspects.

Why do it?

There are several reasons for considering EG Printing, but most of them fall into two categories: financial and quality. How to be more profitable and how to print higher quality labels and packaging. Since the main reason companies are in business is to make money, we’ll start with this one.As most business owners know, there never seems to be the time and the margins they were used to when selling their labels in the ‘good old days’.

With the rising costs of substrates, inks, plates etc and buyers from the companies you sell to demanding lower prices and shorter lead times, it’s becoming harder and harder to make a profit or, worse, stay in business. Since external factors such as the cost of substrate, petroleum prices etc are out of your control then the factors that you do have control over are the internal ones. This is where we’ll focus: how to become more efficient and profitable with the help of EG printing. Since efficiency and cost savings go hand in hand, how can EG help?

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.