Herma to implement automated material flow in new adhesive materials plant

Herma’s new coating plant adhesive materials in Filderstadt, Germany is to play hoist to a fleet of automated vehicles that are to carry large loads around the plant.

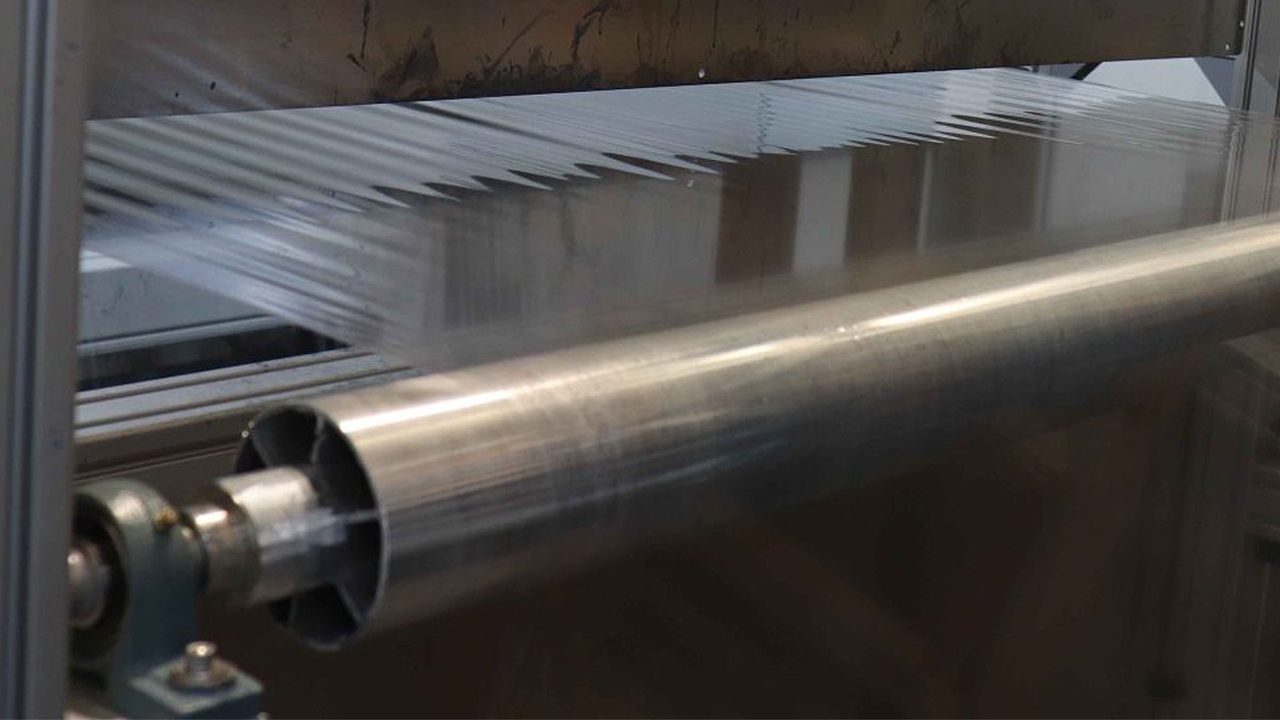

Due to open in autumn 2019, the coating plant will see automated guided vehicles (AGVs) taking care of moving raw materials, such as paper and film, as well as semi-finished products and coated adhesive material rolls.

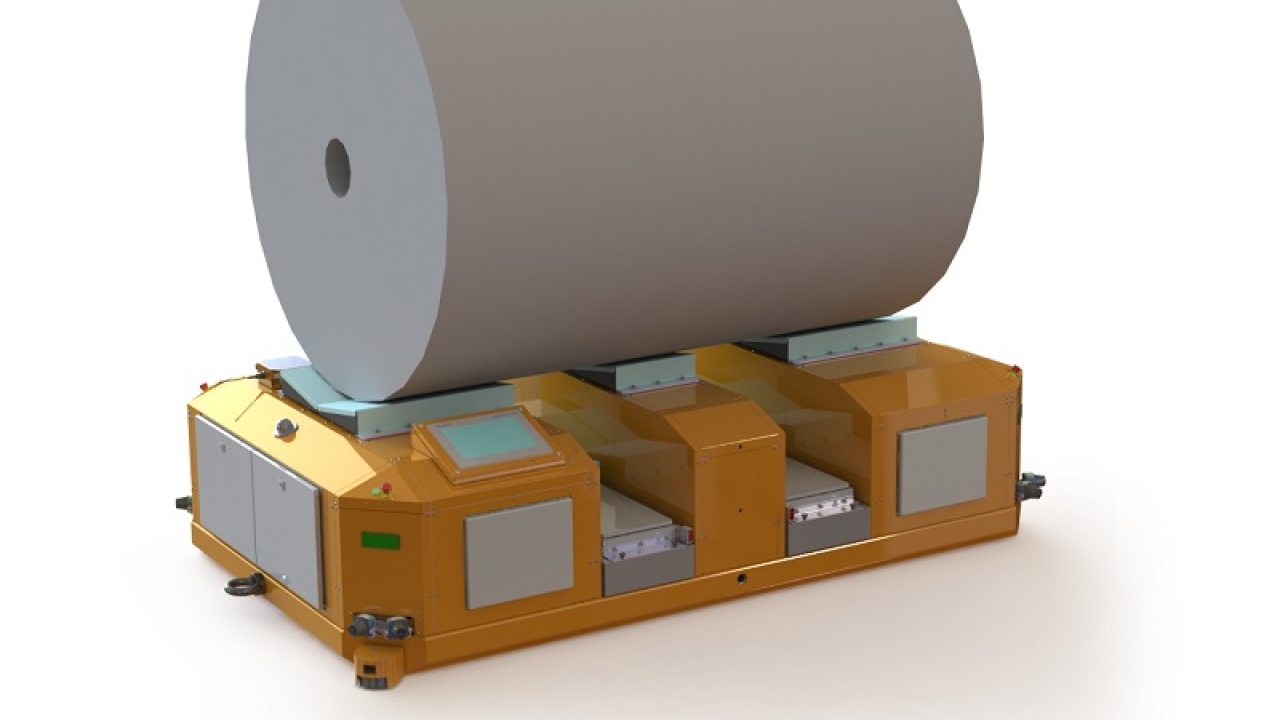

While AGVs are widely used both in printing and other industries, Frank Baude, head of logistics at Herma, explained that this will be a first-of-its-kind in the sector, as ‘the dimensions we require there are not thought to be any precedents in our industry.

‘We are talking about vehicles that are capable of moving rolls that are up to 2m-wide and weigh as much as 4.5 tonnes.’

As reference, the dimensions of an AGV carrying one of these rolls are much the same as those of the large commercial sprinter vans that are so popular with logistics service providers. ‘A lot of research had to be performed in order to find suppliers who were willing to build vehicles with the necessary load capacity,’ continued Baude.

The technology now being adopted by Herma is conventionally used to transport rolling stock, wind turbine blades or aviation fuselages inside industrial assembly halls. A fleet of 10 such AGVs will be navigating their way through the new Herma coating plant. They will be joined by four smaller vehicles with a lower, ergonomic working height. These are to be used where manual operations, such as unwrapping, have to be performed on the rolls.

The aisles in the new coating plant are designed to allow two large AGVs to pass each other. Baude noted: ‘This arrangement also creates a redundant transport system. If an AGV becomes marooned, every location in the production facility remains accessible.’

Each vehicle possesses four wheels that can swivel through 360 degrees, two of which are driven by an electric motor. The AGVs are controlled by multiple integrated scanners, which navigate by referencing fixed points, knowns as landmarks, in the plant. For this reason, neither induction loops nor magnets are required. Some of the defined positions on the coating machines have to be approached with a positioning accuracy of ± 2mm. ‘This is achieved by way of barcodes in the floor, which enable the AGV to identify its correct orientation,’ explained Baude.

The AGVs will take care of all roll movements between the new high-bay warehouse, which is 35 metres tall and has 13 levels, the two coating machines and the slitters. And, for the first time at Herma, none of the materials being moved will require either pallets or other carriers. Rather, the rolls will rest directly on the vehicle bed, whose profile resembles a very flat ‘V’. Baude said: ‘In the past, wooden splinters from the pallets were a recurring problem. They not only gave rise to unnecessary soiling, but also interfered with our transport systems’ sensors.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.