Stichnothe Druckformen invests in CDI Crystal 5080 XPS

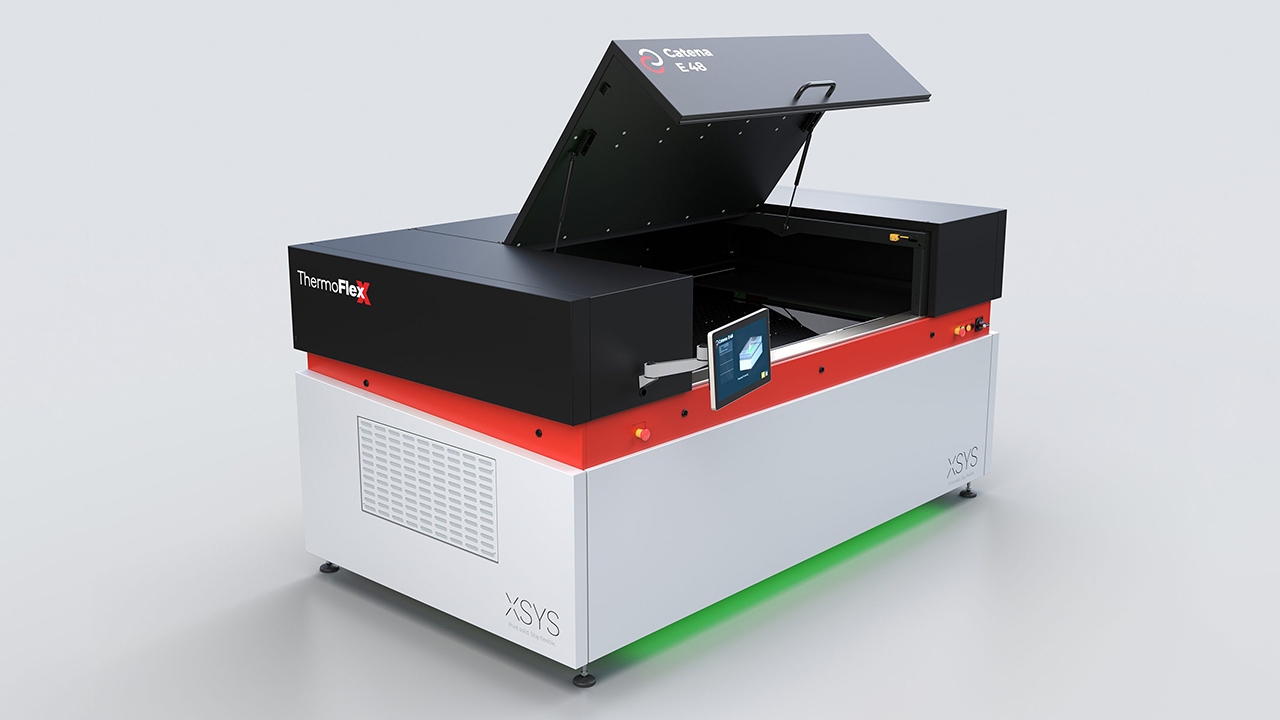

German company Stichnothe Druckformen has invested in an Esko CDI Crystal 5080 XPS, a combined flexo plate imaging and exposure system, to further expand its manufacturing capabilities and production capacity.

As a major provider of flexo printing forms in Germany, Stichnothe Druckformen sought to integrate plate imaging and exposure in a single process to streamline production. With the combined technology from Esko, Stichnothe Druckformen aims to strengthen its presence within the high quality flexo printing segment, especially for flexible packaging.

Dennis Melching, managing director at Stichnothe Druckformen, said: ‘We owe our success in part to our commitment to invest in state-of-the-art technology. This helps us maintain low tolerances across the entire production process. With Esko as a market leader in flexo plate exposure and imaging, choosing the CDI Crystal 5080 XPS was easy. A deciding factor was the fact that the Esko solution is an open system, which means that we are able to image a wide range of different plates.’

The two devices – a CDI Crystal 5080 for flexo plate imaging and an XPS Crystal 5080 for simultaneous UV main and rear exposure – were installed at the beginning of 2018.

Stichnothe Druckformen has worked previously with Esko devices and software. In addition to CDI Spark imagesetters and the corresponding workflow software, the company also uses two Kongsberg cutting systems: one fully automatic, the other with a milling unit.

Melching explained: ‘We apply professional color management, market-leading proofing systems, the latest direct-to-plate applications and special flexo printing software. This ensures that when we get to the review stage, just before plate production begins, everything is ready to start producing the perfect printing form.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.