Covectra introduces system to ensure product integrity throughout the supply chain of infant formula

Covectra has introduced a holistic, integrated serialization-based system for protecting infant formula from counterfeiting.

This system, which has been developed to meet the increasing need for brand and supply chain integrity of infant formula, particularly given the recent increase of illicit trading activity and supply chain leakage in markets such as China, also enables track and trace, and diversion detection of these products through the supply chain and into the hands of the consumer.

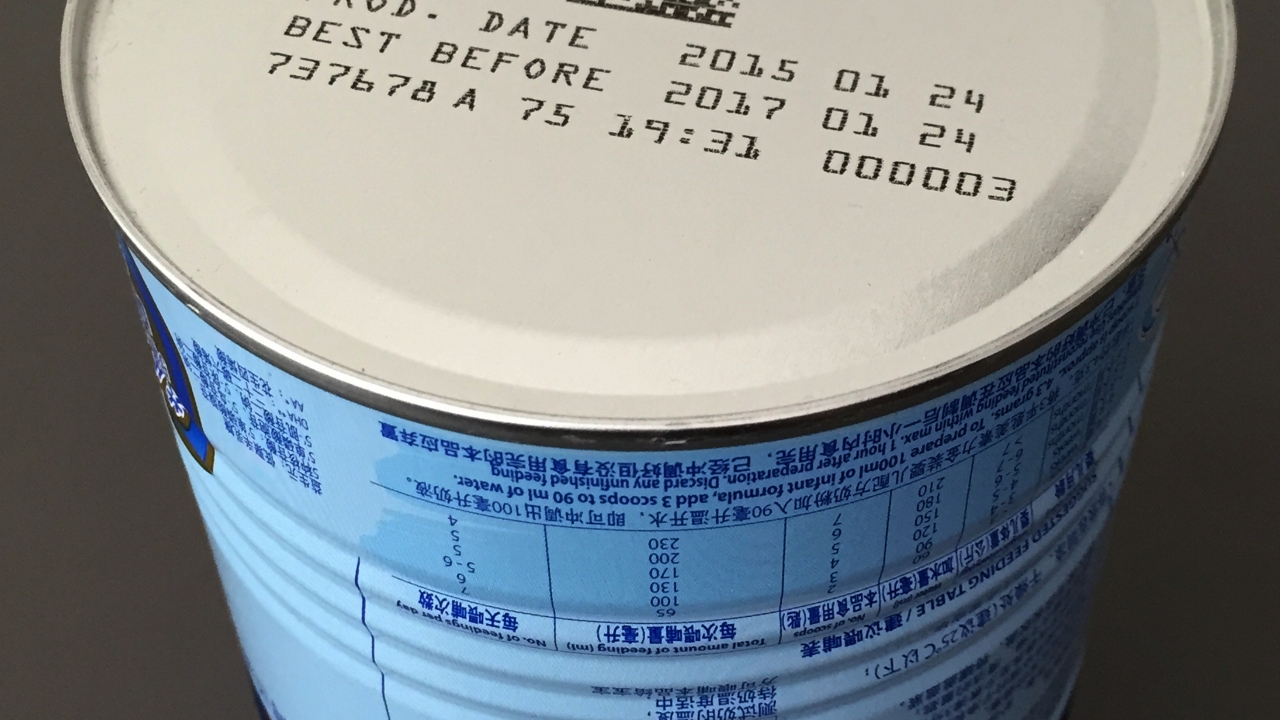

The principle of the system is the application of a serialized unique barcode (QR, 2D or 1D) to the bottom of the can and all levels of packaging (case and pallet) so that it can tracked through the supply chain. Printing is done with a piezo-electric, drop-on-demand printer using UV-curable ink. After the ink is applied, the product is conveyed through a UV curing tunnel. An AuthentiTrack database is used to generate and manage all serial numbers, including all events (e.g. scans) associated with that barcode. A packaging line serialization system using open software architecture and Rockwell Automation technology prints and verifies barcodes on each level of packaging. A downstream supply chain traceability system can be used to track products throughout the distribution system, and to detect incidents of gray market diversion. Supply chain partners are able to re-aggregate reworked pallets that were damaged in shipment. Further, consumer-friendly and secure authentication features can be place on various parts of the can.

Covectra said its proprietary brand protection technology has been developed to enable infant formula consumers, retailers and supply chain partners to authenticate products using the primary package, case and pallet.

Covectra president Steve Wood described managing food safety standards across a global supply chain as ‘complex and challenging’, but said: ‘Steps must be taken to ensure safe and secure shipping and distribution of food products that end up in consumers hands. Our solution was developed to offer a means to identify a brand’s authenticity and to enable visibility of products throughout the supply chain.’

Covectra offers multi-layered brand integrity and protection systems, including its serialization-based AuthentiTrack technology, which includes serial number generation, event repository and event repository management. Covectra is also developing a series of brand protection products for absolute counterfeit detection.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.