Kocher+Beck appoints UK agent

Creation, a UK specialist in packaging artwork, reprographics and sleeve and plate production, has become the exclusive UK supplier of Kocher+Beck rotary screens to the label and narrow web market.

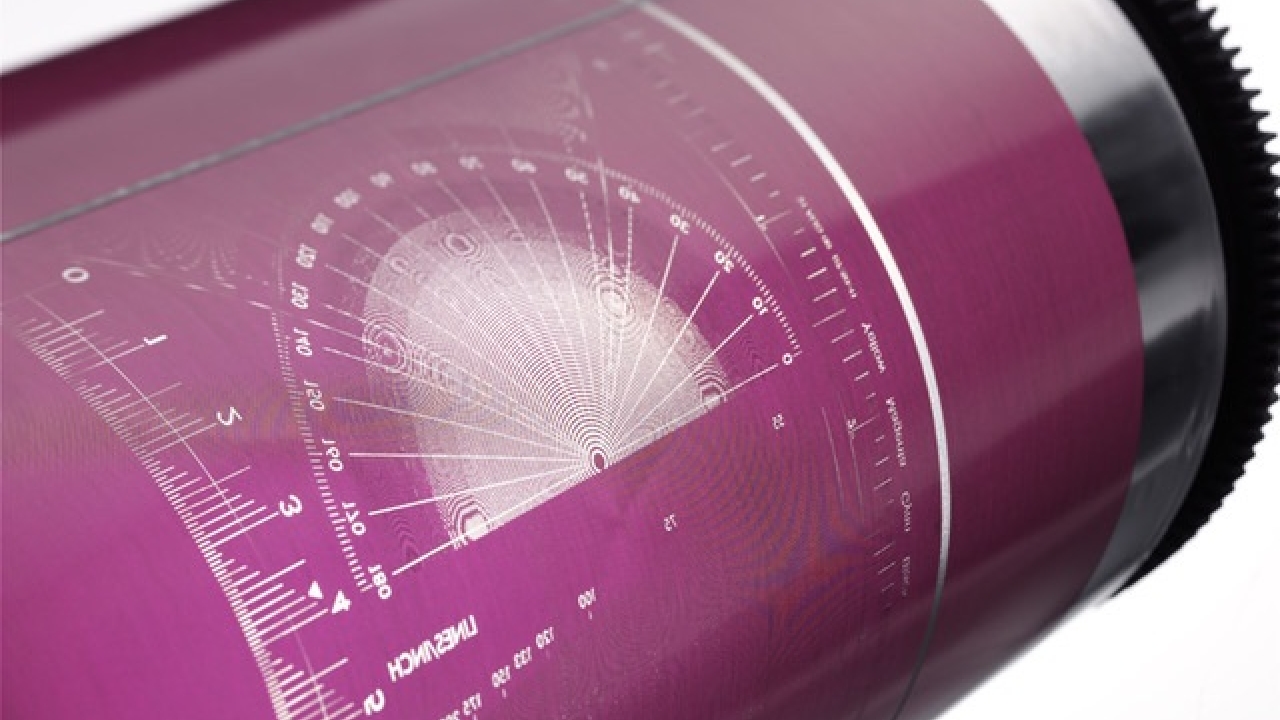

TecScreen from Kocher+Beck is a high definition, pre-coated screen made of a nickel-plated stainless steel material, which is coated with photopolymer and covered with a protector carrier film.

Rick Leivers, sales manager at Kocher+Beck UK, said: ‘With printers under time and cost pressures, the task of effectively manufacturing the stencil for screen printing promptly and cost‐effectively is becoming ever more important. With TecScreen, we can deliver perfect print performance to the print industry with a system that is flexible, cost effective and efficient.’

Matt Francklow, managing director at Creation, said: ‘As the rotary screen market continues to grow, more and more of our customers have approached us asking about screens. As a partner with Kocher+Beck, we can now deliver fast response, premium screen solutions, whether it’s in roll form, sheets cut to size or completely imaged and mounted.’

TecSreen can provide printers with high-definition screen imaging with resolutions of up to 4000dpi, and is designed to ensure consistent quality, accuracy and registration over long print runs. The system is claimed to offer high strength, long life and stability at high speeds, due to its symmetrical and durable fabric. The high contrast red emulsion of the screen printing plate facilitates visual inspection for faults in the pre-press phase.

TecScreen grades cover all common printing tasks and are available for all machine types and screen widths on the market. The system can also reuse any end ring type, including Stork Rotamesh.

Francklow continued: ‘TecScreen offers high speed, high quality printing with the added benefits of reduced downtime and increased efficiency. I believe the register accuracy achieved by the system is highly valued by our customers during welding of the screens and subsequent assembly.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.