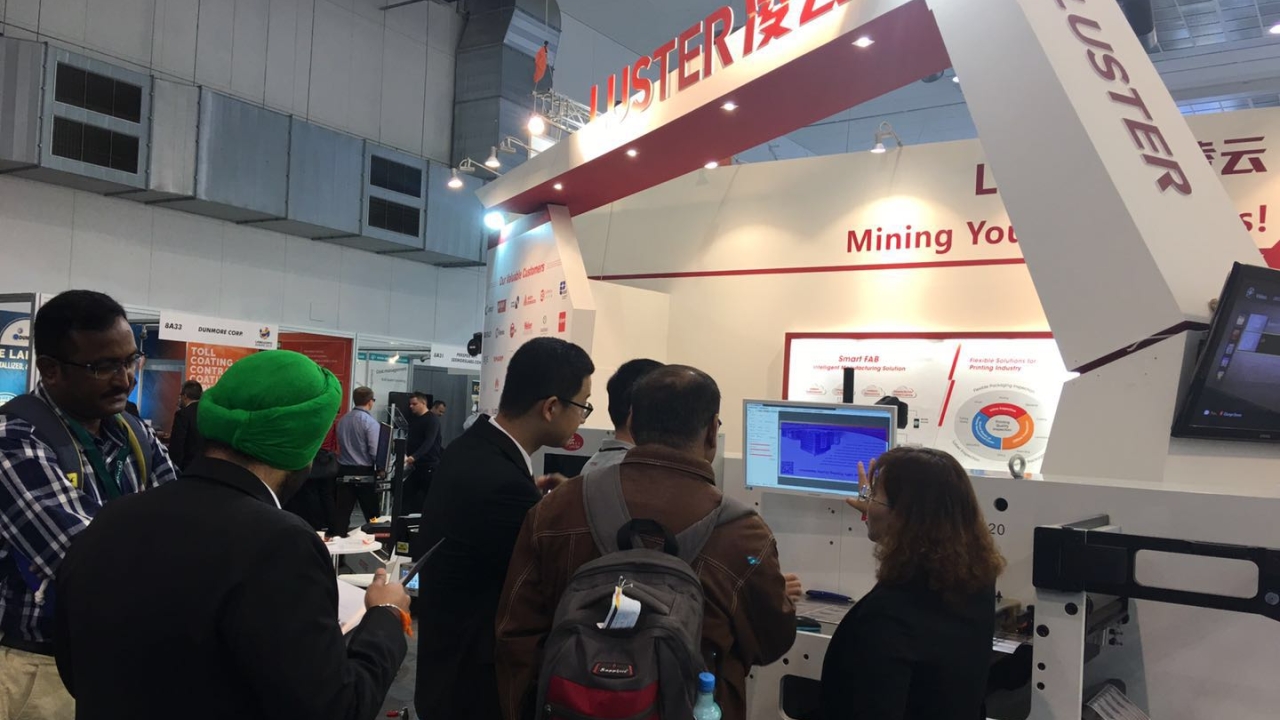

Luster launches LabelRoll at Labelexpo Europe 2017

Luster LightTech Group, a supplier of inspection systems for label, flexible packaging and folding cartons, launched its latest-generation LabelRoll inspection system at Labelexpo Europe 2017.

LabelRoll can detect defects as small as 0.03 squared millimeters and provides accurate defect classification, especially for common issues such as broken words and punctuation. Its double-screen display of both live image monitoring and inspection software enables operators to easily locate defects and accurately control mis-registration as well as other issues.

‘The LabelRoll series are specifically developed for printing quality inspection of electronic labels, daily chemical labels, pharmaceutical labels, food labels and other self-adhesive labels,’ explained Carrie Duan, marketing manager. ‘Able to be applied across the whole label printing workflow, LabelRoll can not only help users to reduce labor and material costs, but also to enhance production efficiency and quality management levels, which means more profit and competitiveness for customers.’

‘Customers can also add a variable data inspection module for accurate barcode and QR code inspection and classification. 3D inspection is also available for defects such as bubble, crease, scratch and excessive glue,’ she added.

Luster also released a new system for in-line color management, which can read up to 220m/min during the printing process. It can support different color modes such as ΔE76, ΔE2000, ΔEcmc with high precision of ΔE≤1.

‘After the four-day exhibition, we realize that people are paying more and more attention to inspection technology in this industry. And more Chinese products are being chosen by global customers because of good quality and service, not only the price advantage,’ said Duan.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.