Printers endorse Herma overlaminating film

Label printers have given an enthusiastic response to their initial experiences with Herma’s new overlaminating film, which was launched earlier this year.

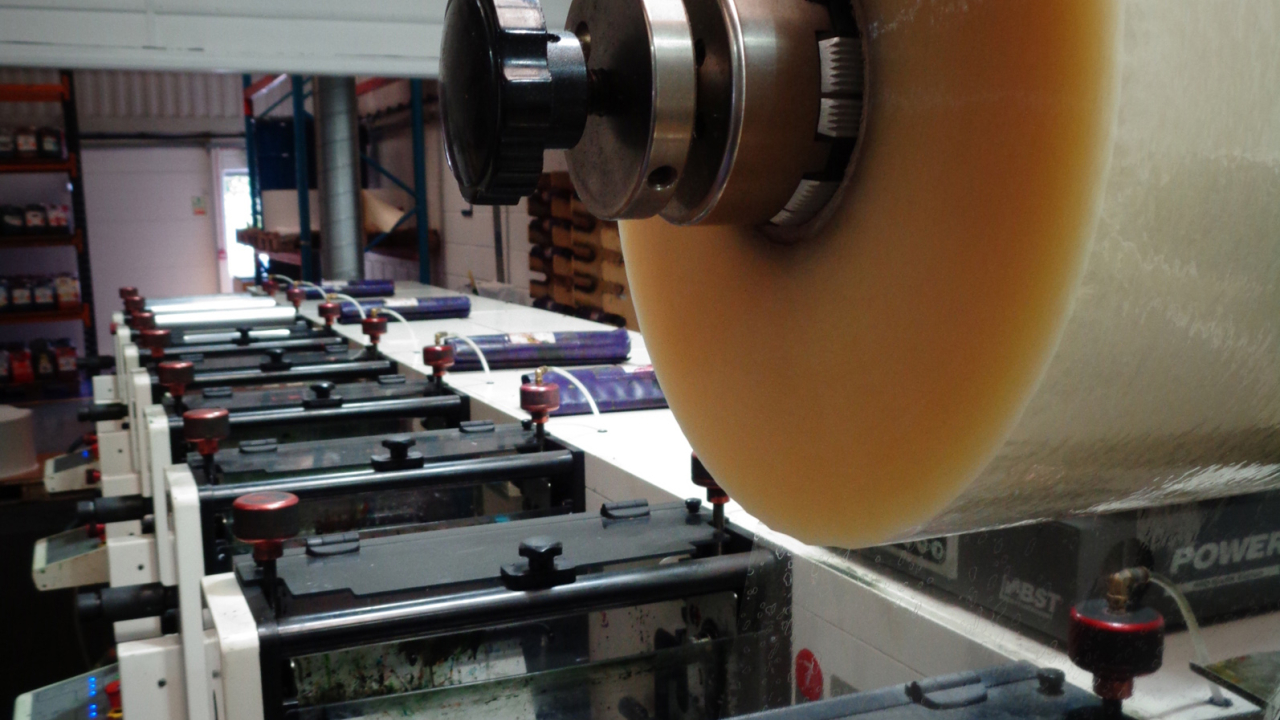

Herma said the overlaminating film provides a ‘simple and affordable way’ of allowing labels, even those made of paper, to withstand harsh and critical environments. It comprises a self-wound, self-adhesive film without liner, so no additional waste is produced during the conversion process. The roll simply feeds in from a spare unwind mandrel and overlaminates the printed media prior to die-cutting. No messy adhesive or wastepack liner recovery is required.

Simon Smith, managing director of CS Labels, said: ‘It helps to protect our labels effectively from cracking or rubbing if the application demands it. It also makes the label resistant to chemicals and the elements.

‘Aesthetically, the overlaminate adds a very high-end gloss finish, so for certain premium products and brands, it can really help to sell the client's product.’

For CS labels, the appearance plays an especially critical role as specializes in Color-Logic technology which, thanks to special toners, can create an array of special, particularly metallic, effects.

‘Herma’s overlaminate offers an excellent seal for this purpose that protects the label and lets the colours shine,’ adds Smith.

Mission Labels concentrates on conventional flexography. In its case, Herma's overlaminating film has been instrumental in extending the company’s product portfolio.

Dave Humphrey, technical director of Mission Labels, said: ‘We were primarily a supplier of labels to manufacturing industry, but the overlaminate has enabled us to diversify into other areas, such as chemicals, automotive and cosmetics.

‘We now have labels in service even on drilling platforms in the inhospitable North Sea.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.