Scientists develop new way of attaching electronic screens to paper-based packaging

Scientists at the University of Sheffield in the UK have developed a means to print an electronic screen on packaging to display information.

The scientists collaborated with technology company Novalia for the process, which involves printing electronic tracks onto paper and then fixing low-cost electronics and a polymer LED display to the paper using an adhesive that conducts electricity.

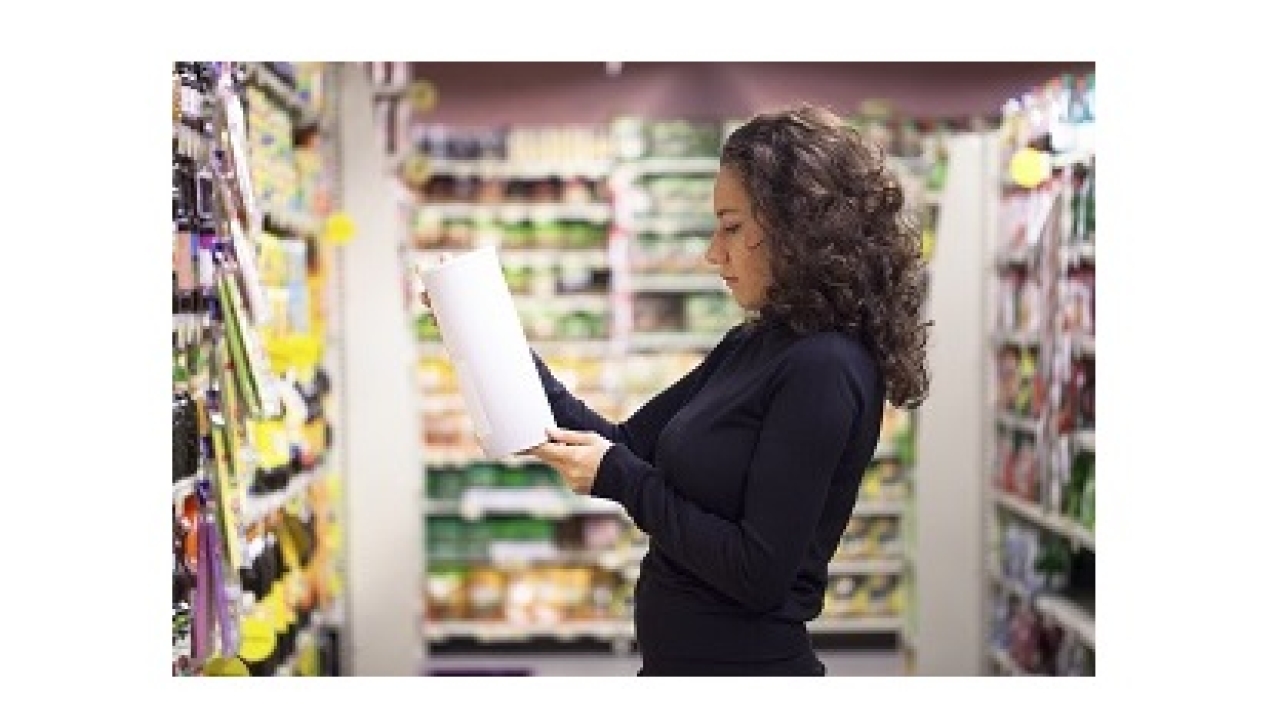

The technology could be used in greetings cards or products where a customer could receive a simple message. More complex developments could include a countdown timer on the side of a packet to indicate when a timed product is ready – such as hair dye, pregnancy tests or home baking using a traffic light system.

University of Sheffield scientists and Novalia have also designed and constructed a touchpad keyboard on the paper that allows a user to selectively ‘drive’ the LEDs in the display. The team’s next steps are to create fully flexible organic displays on a plastic substrate that then fix onto the electronic tracks. The LED devices need to be low-cost and flexible enough to be used on all packaging.

The development is explained in a paper published in the IEEE Journal of Display Technology.

Professor David Lidzey from the University of Sheffield’s Department of Physics and Astronomy said: ‘Labels on packaging could become much more innovative, and allow customers to interact with and explore new products. The use of displays or light emitting panels on packaging will also allow companies to communicate brand awareness in a more sophisticated manner.’

Novalia’s Chris Jones added: ‘The paper-based packaging industry is worth billions of dollars. This innovative system we have developed with the University of Sheffield could give manufacturers a way to gain market share by being able to distinguish its products from competitors.’

The research has been funded by the Engineering and Physical Sciences Research Council (EPSRC) and testing so far has taken place on paper but the process could potentially be printed on other surfaces.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.