Shilp Gravures invests in Full HD Flexo

Ahmedabad-based Shilp Gravures has installed Esko’s Full HD Flexo system, a combination of in-line UV2 technology on its CDI 4260 digital flexo imager and special screening, to match the quality of flexo to gravure.

Shilp Gravures is acknowledged as a leading Indian gravure cylinder trade house. In 2009, Shilp acquired a leading flexo trade shop – an existing user of Esko pre-press and digital imaging for flexographic plates.

The company was amongst the earliest to invest in Esko software products such as Flexo Tools and HD Flexo imaging in 2012.

Shilp Gravures said this has been in response to and in preparation for changes in the Indian market, with narrow and wide web flexography growing in the country and even gravure printers adding wide web central impression cylinder (CI) flexo presses for flexible packaging.

Since 1997, when the first Esko system was installed at Shilp, it has been an exercise of constant growth, expansion and new technology and refinement for both of the companies. As the flexible packaging industry grew in India, the global quality standards required by the consumer product companies had to be met and Shilp continued to exercise its leadership position in the industry by adding the latest technology in pre-press and electronic engravers. In fact, the company became an exhibitor at drupa as a supplier and exporter of engraved cylinders.

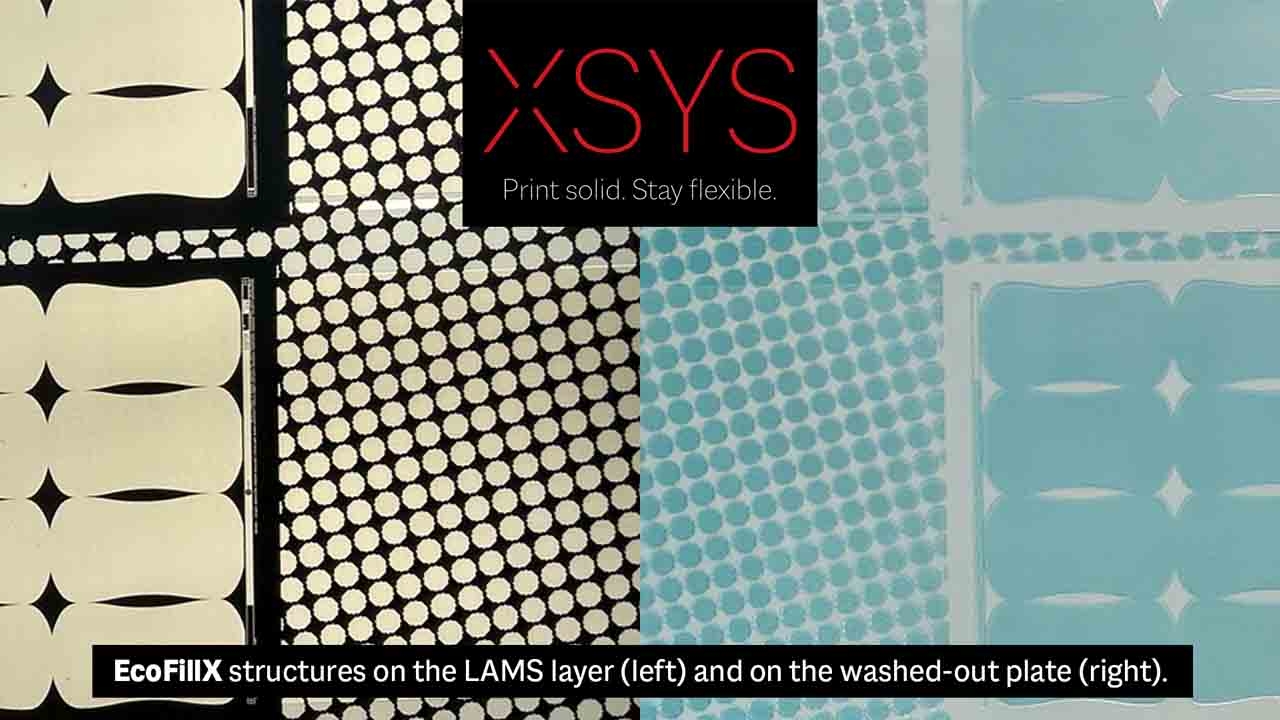

Esko Full HD Flexo allows flexographic printing to compete with offset and gravure quality. The Esko CDI 4260 installation with in-line UV2 provides a combination of special micro screening for smooth vignettes, sparkling highlight detail, vibrant brand and spot colors, and high solid densities.

By adopting innovations like Esko Full HD Flexo in-line UV2 on its CDI imager, and with its own comprehensive knowledge in flexible packaging, Shilp said it has been able to move flexo quality ‘to the next level’ for packaging and label printers and converters.

Gajanan Bhavsar, Shilp Gravures marketing director, said: ‘This was the only technology that gave us the best flat top and round top dots in the same flexographic plate, with results close to offset and gravure quality.

‘We have been waiting for years to achieve gravure quality with flexo plates as it is a faster, more flexible and cost effective process. Finally Full HD Flexo gives us this breakthrough so it’s now possible to move the highest quality work from gravure to flexo which is what some of the leading brand owners want.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.