Skymark, AIMPLAS, PureLoop partner for recycling of printed films

UK flexible packaging manufacturer Skymark has collaborated with EU partners to develop technology that enables printed films to be recycled by removing contaminants and odor that can hinder the downstream process.

Under the CLIPP+ project, a Horizon 2020 research and innovation program, Skymark said it can now create environmentally friendly recycled polyolefin (PE) films to be used in non-food packaging applications. The technology uses carbon dioxide as a cleaning and stripping agent in super-critical conditions. The recycled printed PE film is suitable to be used in various higher added value primary and secondary packaging applications, such as film for wrapping tissue packs.

Alan Heappey CChem MRSC, project manager at Skymark, said: ‘Currently, most waste printed plastic packs are considered to be non-recyclable, having a very low added value and their use is limited to low-cost applications, energy recovery and landfill disposal.

‘We wanted to create added-value plastics via recycling from post-industrial waste by offering reprocessed PE film that provides optimal mechanical, aesthetic and thermal properties as a substitute for virgin polymers.’

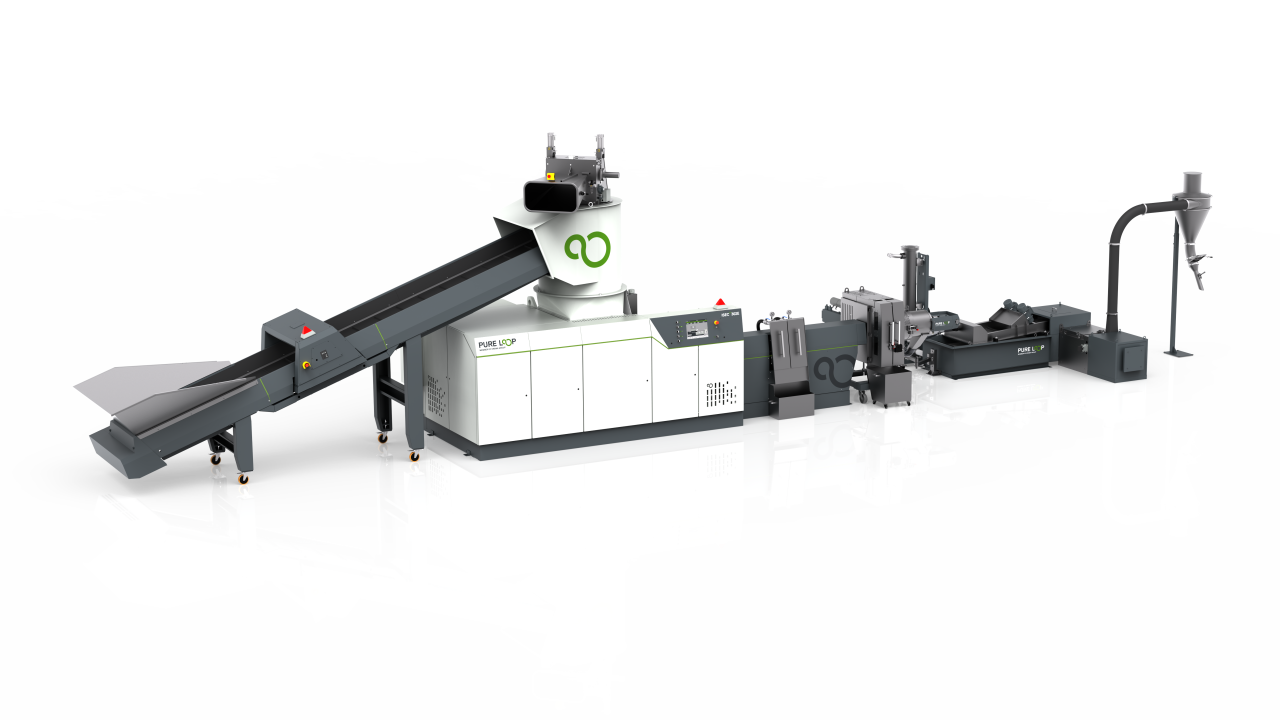

Skymark has been coordinating the project since 2015 working alongside AIMPLAS, a plastics technology center in Spain, and PureLoop, a member of the Erema group and a European machine manufacturer. Skymark has invested in the first commercial machine, which is being manufactured by PureLoop in Austria, and will be installed shortly at Skymark’s headquarters in Scunthorpe.

Heappey commented: ‘It has been exciting to see the full-scale PureLoop machine coming to life and has been rewarding to work with AIMPLAS and PureLoop who are both experts in their particular fields. Thanks to the team, the concept of adding CLIPP+ technology to a reclamation machine has now become a reality.

‘Through strong collaboration, we believe we have jointly created a process that will contribute to the production of more sustainable packaging. The technology will increase the profile and capabilities of the polymer recycling industry, which is currently being steered by increasingly stringent legislation on packaging and packaging waste.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.