AB Graphic launches upgraded screen printing unit

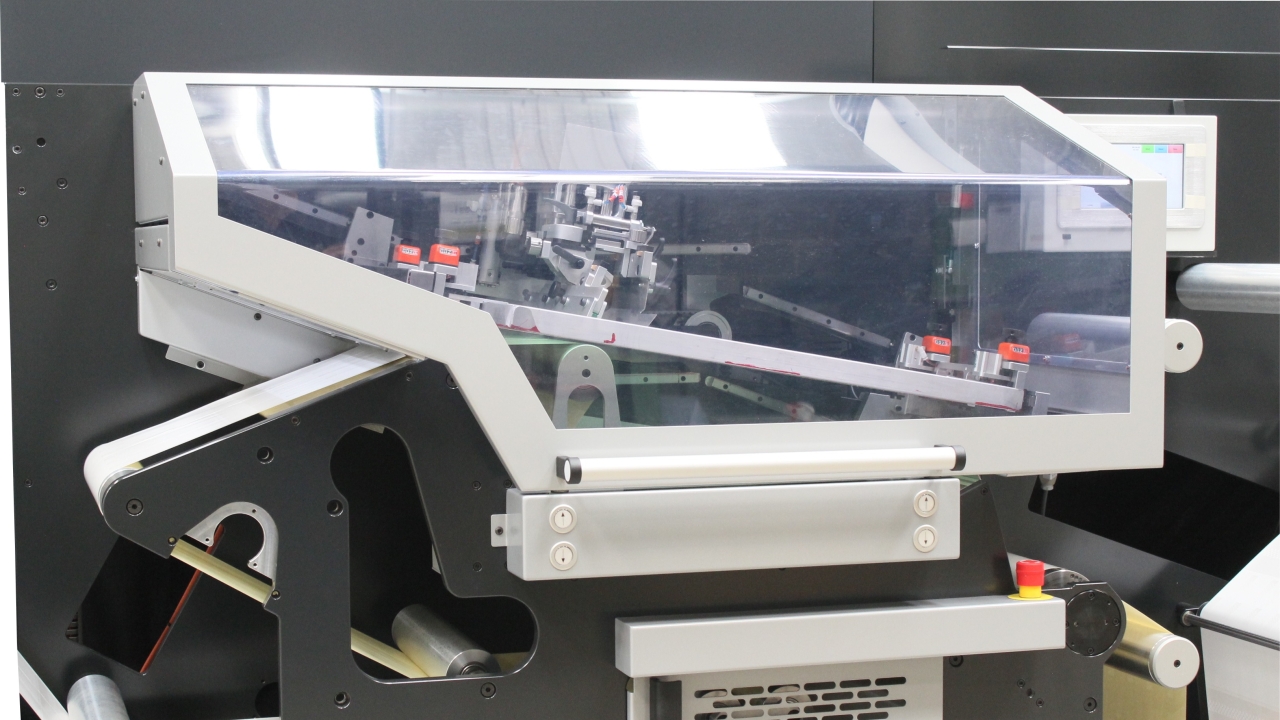

AB Graphic has developed an upgraded flat screen printing unit, to increase the running speed in line with other elements of its Digicon Series 3 finishing machine.

Debuting at Labelexpo Europe 2017, the new module has a full rotary web motion, whilst still using a flatbed screen. AB Graphic said the quality of UV curing is also improved by the rotary web motion. The physical size of the module has been reduced by over 20 percent, while the repeat area has increased to 410mm in the web direction. This last enhancement makes it compatible with AB Graphic’s Big Foot 50 hot foil stamping unit. There is also a chill roller option for delicate substrates.

Motorized lateral and skew adjustments for screen image position, plus on the run servo adjustment of the squeegee and scraper position, make it easy for the operator to adjust the level of ink through the mesh and onto the web.

Tony Bell, sales director at AB Graphic, explained: ‘Flat screen printing is traditionally the slowest module on any finishing machine. At Labelexpo Europe 2017, we’ll be launching our new flat screen printing unit, which has a significantly increased running speed.’

AB Graphic also showcases a number of fleyeVision inspection systems at Labelexpo Europe 2017.

‘Our fleyeLink Workflow manager creates a roll map of defects that can be doctored in a final process to eradicate substandard labels,’ added Bell.

‘Using a barcode printer for closure labels on the end of the turret, the small rolls with faults can be identified and then run quickly through small rewinder that highlights where the errors are, ready to be doctored. It’s a very efficient way of getting product through the finishing department quickly to the end user, completely safe in the knowledge that all rolls are of the highest quality.’

Read L&L's comprehensive Labelexpo Europe 2017 preview in issue 4, and here

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.