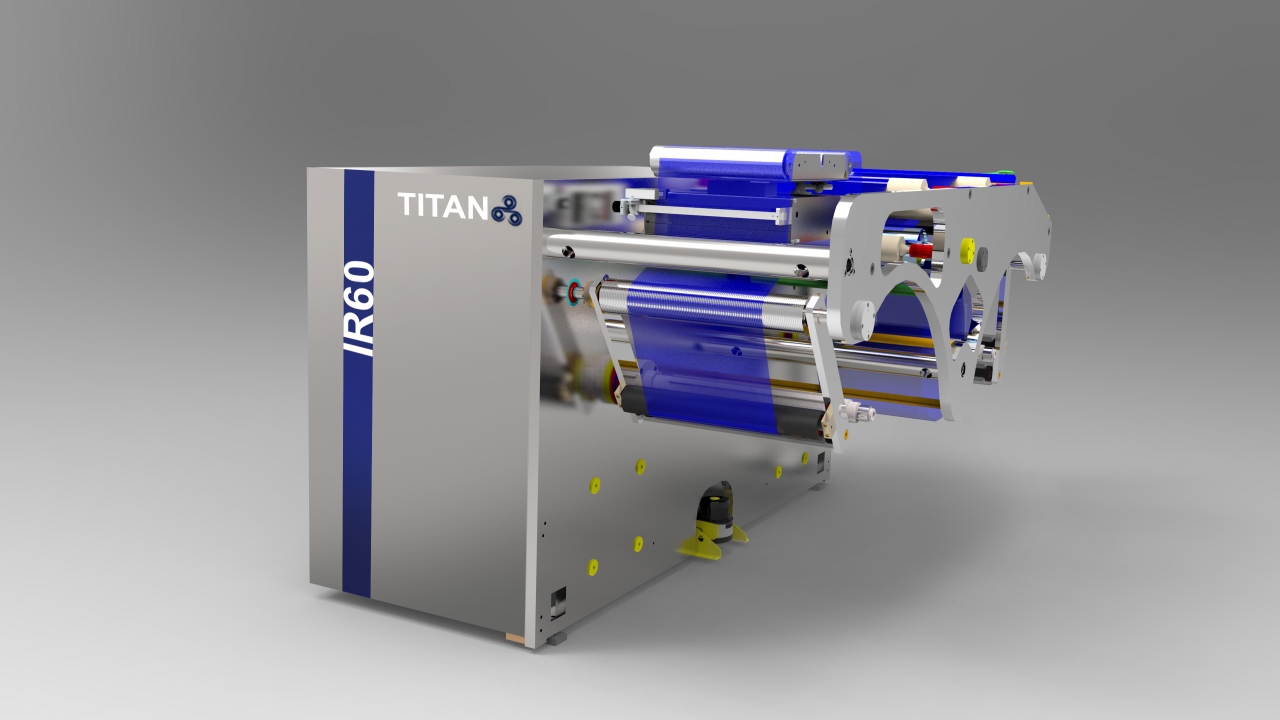

Atlas adds Titan inspection rewinder machines

Atlas Converting Equipment is to introduce a range of inspection rewinder machines to complement its Titan range of slitter rewinders.

To be launched at ICE Europe, running March 21-24 in Munich, Germany, the IR60, IR135, IR165 and RR165 models are designed to meet the market requirement for different web widths and complement the range of Titan slitter rewinder machines. The Titan series of inspection machines will unwind, inspect and rewind material from 60cm (24in) to 165cm (65in) widths to improve the quality of the mother rolls that go into the slitter rewinders, eliminating the need to stop the slitter therefore increasing the slitting efficiency and slit quality.

They can process laminates, film, paper, metalized film and aluminum foil.

The IR135 and IR165 compact inspection machines can also be used to splice together smaller mother roll diameters and deliver a larger mother roll, again increasing efficiencies of the slitter. The RR165, with its overhead web path, can also incorporate additional valued added processes such as web laser perforation/scoring and other web treatments.

Identifying defects on the web can be done either by a fully automatic 100 percent inspection system, manually using stroboscopic systems or by entering multiple stop signals based upon the flag location. The machines are high speed, fully reversible and with the inclusion of splice table the operator can remove all defects greatly reducing waste and time.

Barrie Homewood, sales director for Titan products at Atlas Converting Equipment, said: ‘These inspection machines complement our range of Titan slitter rewinders and deliver enhanced slitter productivity and quality for our customers; real productivity improvements are seen when large diameter “clean rolls” are supplied to the slitter rewinder.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.