BST ProControl launches PC16S-wave RS reflection sensor

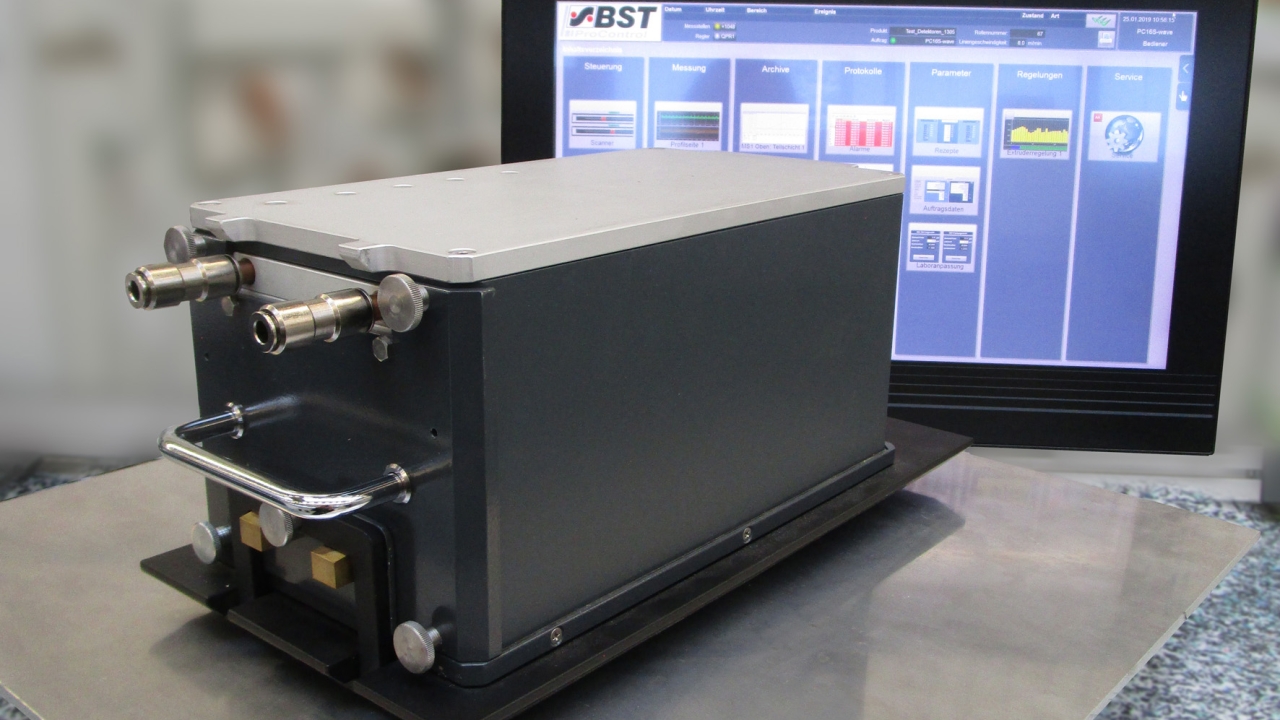

BST ProControl, a business unit of BST eltromat, has launched a new reflection sensor to allow high-precision measurement of coatings on metallic substrates.

The PC16S-wave RS reflection sensor measures the material web without contact using non-ionizing electromagnetic waves. The interaction of the non-ionizing electromagnetic waves with the material includes the waves being absorbed. Depending on the basis weights and composition of the coating to be measured, the measurement signal is weakened. The time-resolved measurements capture the weakening of the signals and provide precise measurements based on them. For PC16S-wave RS, the electromagnetic waves emitted by the sensor are reflected from the metallic substrates. Based on this, the weakening takes place on the two-time passage of the waves through the coating that is being measured. Due to the absorption-based measurement in reflection with the PC16S-wave RS, it is a one-sided measurement method.

PC16S-wave RS builds on the PC16S-wave TS transmission sensor. All sensors in the PC16S-wave family use non-ionizing electromagnetic waves. As a result, they do not require licensing and regulatory approval. In contrast to sensors that use ionizing radiation, BST ProControl noted that neither PC16S-wave TS or PC16S-wave RS are subject to the requirements of national or international authorities for transport, operation or disposal. They are also said to exhibit ‘outstanding’ electromagnetic compatibility (EMC) characteristics, making the sensors applicable for a wide range of measurement tasks. The measurement of coatings on metallic substrates is widely required in the manufacturing of food packaging. Further, they do not interfere with other equipment or pose a health hazard to employees, BST ProControl added.

Dr Frank Blecher, head of development at BST ProControl, said: ‘This new sensor gives our customers a wide range of options for measuring coatings on metallic substrates with maximum precision. For example, this might be aluminum foil for packaging that has been laminated, painted or coated.’

Mathias Klein, project manager at BST ProControl, added: ‘The PC16S-wave TS is now used by customers all over the world, including in the control of calenders. With its non-contact absorption measurement method in transmission, it measures the basis weight of polymer-based mono foils extremely precisely and quickly. We plan to bring the new PC16S-wave RS reflection sensor onto the market in the second half of 2019.’

In 2013, BST eltromat founded BST ProControl as a 100 percent owned subsidiary through the acquisition of betacontrol and Protagon. From the start of 2017, BST ProControl has been completely integrated in BST eltromat’s commercial procedures and has since been run as an integrated and independently operating business unit of the company at its location in Wenden, Germany.

Siegfried Steggemann, head of the BST ProControl business unit at BST eltromat, added: ‘The high-performance range of sensors from BST ProControl is the key to the successful realization of demanding measurements, such as basis weight and thickness. For example, the use of raw materials can be reduced while improving production quality.’

PC16S-wave RS was presented at ICE Europe 2019, where BST eltromat also formally confirmed majority ownership of Nyquist Systems.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.