Kroenert debuts coating unit for simultaneous double-sided siliconizing

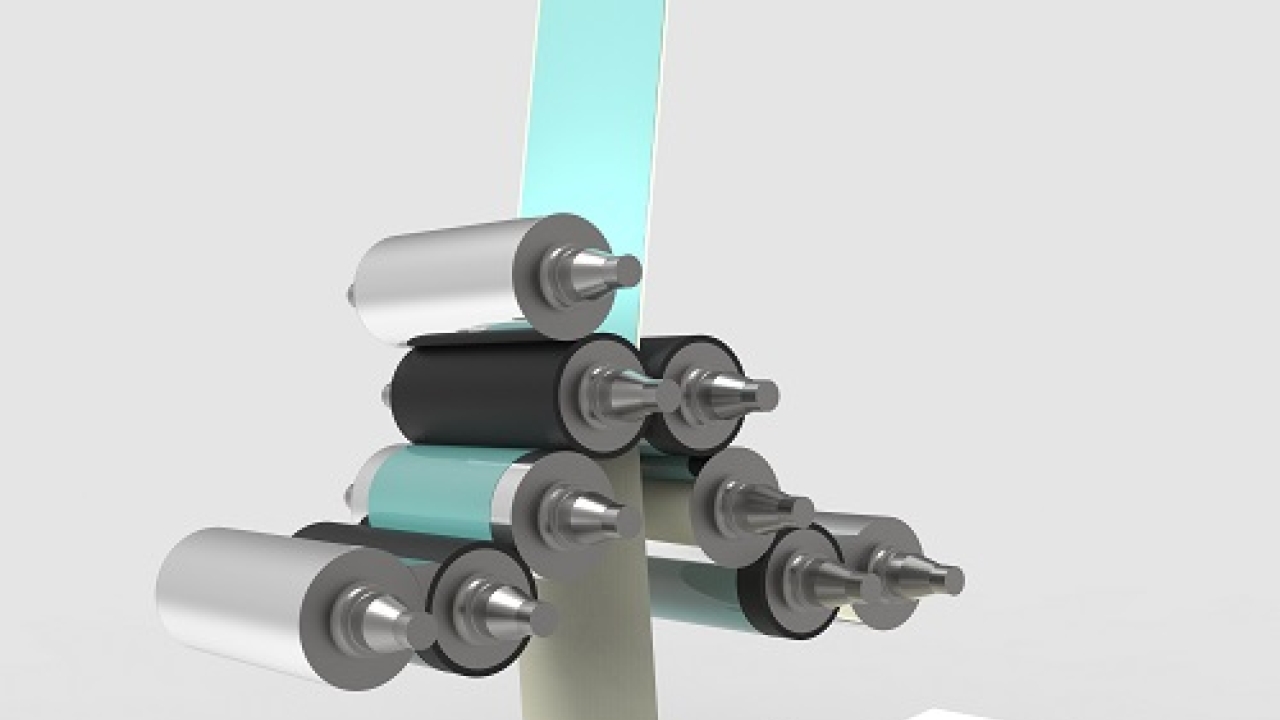

Kroenert, a specialist manufacturer of customized coating, printing and laminating systems, has developed a coating unit for simultaneous double-sided siliconizing webs.

Claimed as a first, the coating unit allows simultaneously siliconizing of both sides of a web with solvent-free silicones. This has seen Kroenert redesign a roll-to-roll system especially for this purpose.

This coating unit can be included in new plants or retrofitted in existing facilities. Retrofits allow the flotation dryer already installed in many plants to be used for the non-contact transport of webs and combined with a non-contact air turn in front of the dryer. This feature cuts down on costs for equipment and operations and minimizes environmental impact, according to Kroenert.

The process of double-sided siliconizing is identified as especially suitable for paper webs used as release liners for adhesive tapes, for example, and for graphic products. The simultaneous coating of the front and back of paper webs substantially prevents paper from drying out and the coating machine can be considerably shorter in length, taking up less space. Moreover, the system requires less operators, allowing one person to oversee two coatings at the same time. As only one dryer is needed, this process is very resource-efficient and consumes less energy. The siliconizing unit can also be utilized for one-sided coating and operate flexibly with other substrates and silicones at any time.

Wolfram Szczepaniak, head of technology at Kroenert, said: ‘Our new siliconizing unit has proven successful in practice and is an outstanding addition to our portfolio of top-quality products, which to date includes systems primarily with gravure rollers for double-sided coating.

‘The expansion of our product lines of efficient coating solutions is an ongoing process and we are already testing the next developments in our technology center.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.