Xeikon launches Panther DuraCure curing technology

Xeikon has developed Panther DuraCure, UV curing technology for use with Xeikon PantherCure UV inkjet inks.

Panther DuraCure curing technology is a unique technique combining UV LED and conventional technologies to deliver optimal gloss effects in all colors, as well as ‘ultimate durability’ for multiple applications across multiple sectors. Key benefits are identified as consistent curing performance, long-term durability, and the lowest possible energy consumption.

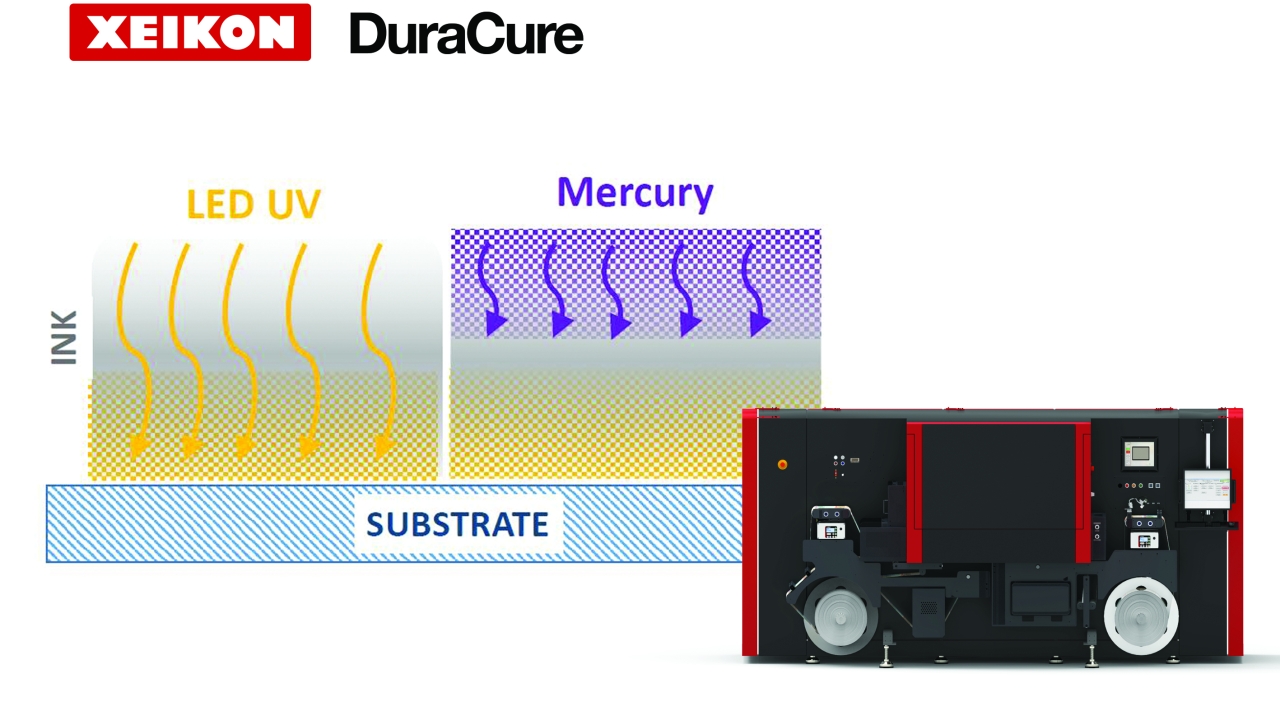

Working with the Panther UV inkjet series of digital presses, the Panther DuraCure curing process operates in a number of ways. UV pinning of white keeps the ink from spreading and bleeding into the CMYK inks. This ensures that the quality of the CMYK image is kept at the highest level. UV pinning after black following CMYK transfer means DuraCure ‘freezes’ all colors across the image and maintains a uniform optimal color brilliance and gloss. The use of UV LED curing, with its ability to go deep into the ink layers, combined with HG or mercury curing for lightly but effectively curing the surface of the UV ink, ‘offers the best of both worlds’, according to Xeikon, and takes it Panther UV inkjet series of digital presses ‘to new levels of performance’.

‘The intelligent use of these existing technologies is what makes the difference,’ the company noted. ‘Combining them in an optimal way to use less energy has a positive impact on the lifetime of the curing lamps.’

Jeroen Van Bauwel, director of product management at Xeikon, said: ‘In response to industry demand, DuraCure is the next step forward in our strategy to provide a portfolio of complementary solutions. Good curing performance is an important factor when looking to invest in UV inkjet printing technology. The quality and durability of DuraCure expands the capabilities of this printing technology and makes it a very attractive opportunity.

‘The new DuraCure technology can achieve optimal curing for a variety of applications, it combines with our PantherCure UV inks and substrates to achieve the highest quality results and provide added value business opportunities for our customers.’

Xeikon has applied to patent its Panther DuraCure UV curing technology for use with Xeikon PantherCure UV inks.

Van Bauwel explained: ‘The combination of all these curing steps results in the most durable, sustainable and effective curing solution on the market today. This is why we have applied to patent our Panther DuraCure curing technology. Xeikon continues to work towards excellence to enhance every facet of its portfolio. With our very long history and substantial knowledge of the digital label printing market and our access to market leading technologies as part of the Flint group, we can provide our customers with the very best products and services.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.