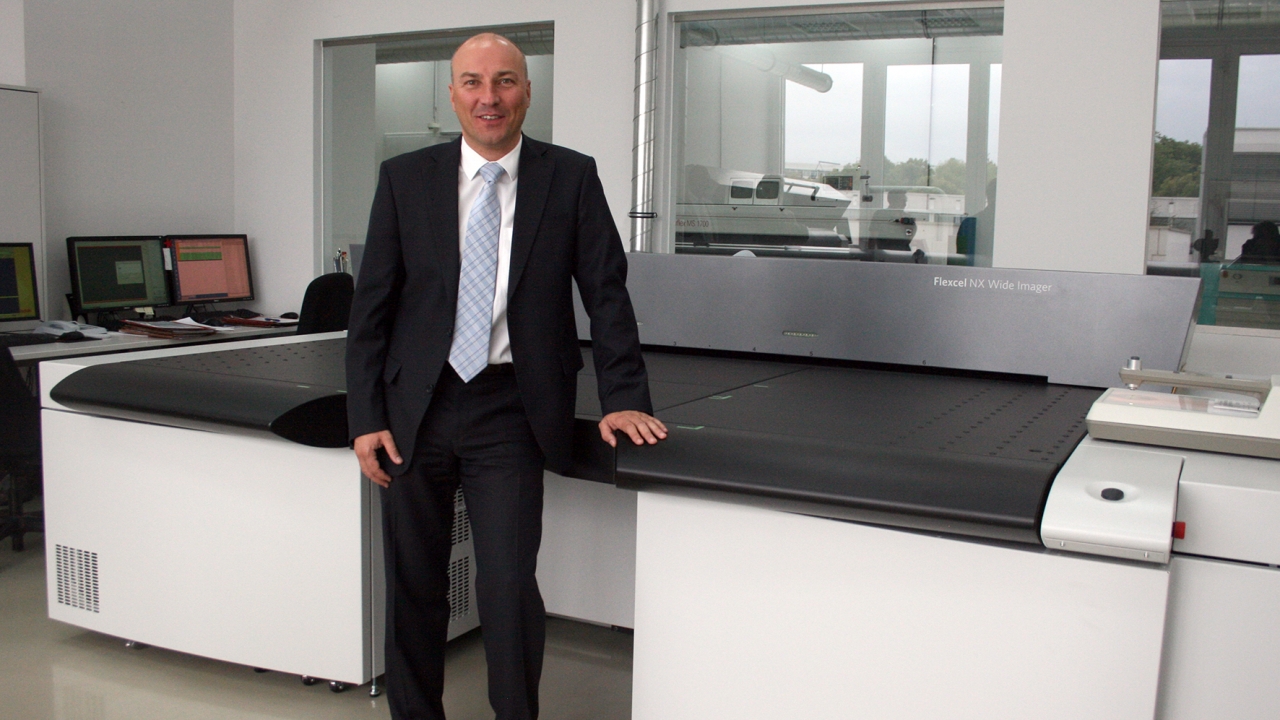

German repro house installs Kodak Flexcel NX Wide system

Munich, Germany-based Reproservice Eurodigital, a member of Matthews Brand Solutions, has invested in the Kodak Flexcel NX Wide system.

Reproservice Eurodigital supplies digital flexo plates to packaging printers and brand owners, mostly for solvent and UV flexo printing on plastic film, aluminum and other substrates. Plates for higher-fidelity presswork are typically made in 175 lpi.

The Flexcel NX Wide system enables the platemaking specialist to produce flexo plates up to 1067 x 1524mm. Reproservice Eurodigital has been a user of the Flexcel NX Mid system since August 2009.

Managing director Peter Hamm said: ‘The system lets us reproduce the key 42 x 60in flexo press format. This larger plate size is essential for meeting our customers' needs and with the help of the Flexcel NX Wide system, we can now also print up to a maximum width of 1400mm without having to mount the plates twice.’

The new system exploits the Kodak Flexcel NX Wide imager to achieve high-resolution imaging of the Flexcel NX thermal imaging layer. This results in a negative mask, which is laminated onto the Flexcel NX plate in the Flexcel NX Wide laminator, so that the sharp-edged mask image is in intimate contact with the photopolymer plate's surface. All subsequent steps with UV exposure are the same as when photopolymer flexo plates are processed in the normal way.

Kodak Squarespot imaging technology, coupled with platemaking using the Flexcel NX Wide system, ensures well-defined flat top dots on the plate. This is true with even the finest highlight dots, which have sturdy bases, just like the dots of the higher tones.

‘With the Flexcel NX system, we no longer have to resort to a special curve to bump up the highlights,’ said Hamm. ‘If necessary, we can even reproduce stable tonal values below 1 percent on the plates. Compared to classic digital LAMS technology, the tonal range is definitely larger. The sturdy dot bases guarantee consistent printing results. And screen builds explicitly adapted to one-off situations and substrates are a thing of the past.’

Thanks to the ultra-high resolution of Kodak Squarespot imaging technology, the Flexcel NX Wide system also supports Kodak Digicap NX Screening. Digicap NX Screening is a software-based feature for the Flexcel NX system that improves ink transfer efficiency through the application of a micro surface texturization pattern to the surface of all elements on the Flexcel NX plate. Print applications that traditionally struggle with efficient ink transfer can now enjoy higher print densities, smooth solid area ink coverage and expanded color gamut with process printing. Feedback from printers that have already purchased Flexcel NX plates from Reproservice Eurodigital confirms the potential 25 percent increase in the ink densities printed, and emphasizes the newly mastered ability to print finer highlights.

According to Hamm, flexo printers are impressed by the high on-press stability of the Flexcel NX plates. The majority of orders received are for 1.14 or 1.7mm-thick plates, however Reproservice Eurodigital can also supply Flexcel NX plates 2.28 or 2.72 mm thick.

The larger format enables Reproservice Eurodigital to transfer jobs which previously would have been turned down on account of the size from LAMS systems to Flexcel NX technology. In addition, more color separations on one plate are now possible for jobs with smaller sizes.

‘If we use Digicap NX Screening, the full format is imaged in just eight minutes. That’s the equivalent of almost thirteen square meters an hour,’ said Hamm. ‘In other words, the Flexcel NX Wide system gives us roughly three times the imaging productivity of the latest generation of LAMS CTP systems at the high end of the market.’

Pictured: Peter Hamm, managing director of Germany-based Reproservice Eurodigital

Click here for more stories about Kodak on L&L.com.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.