South Africa’s evolving label market

Sustainability and highly embellished labels are trends dominating this dynamic region.

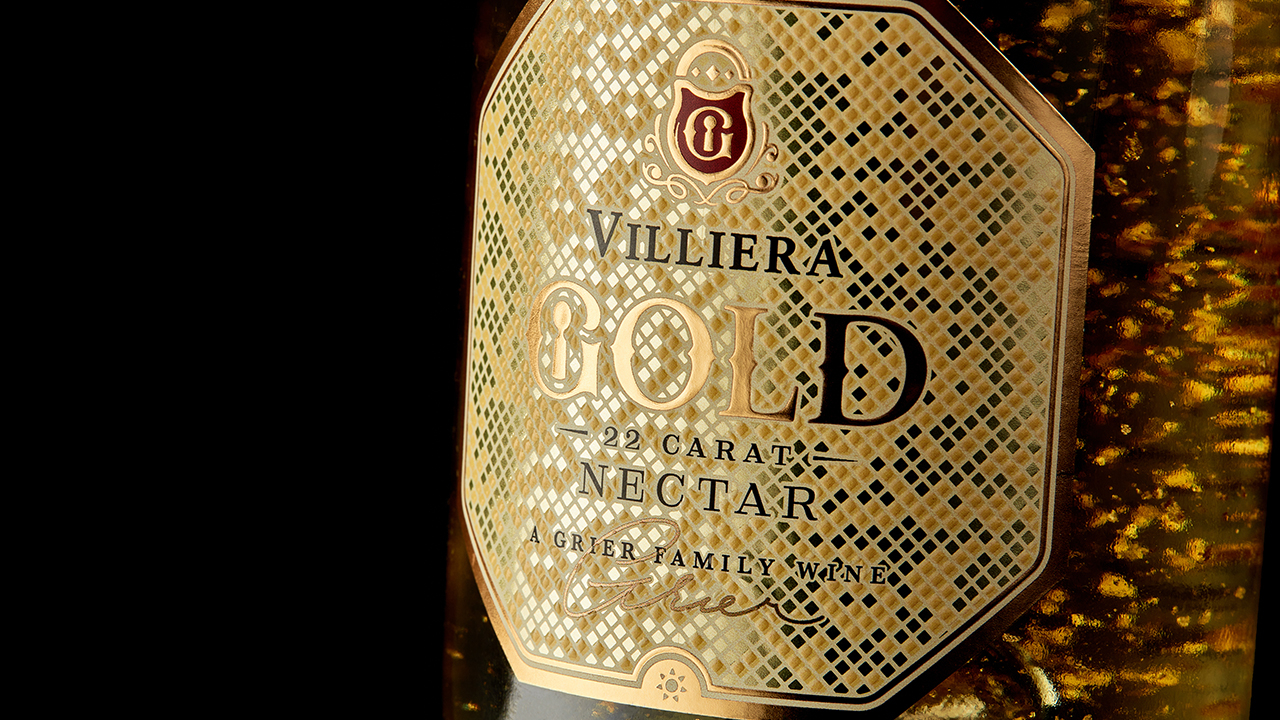

Highly embellished labels thrive in South Africa's wine label market

In the high-stakes race for shelf appeal, wine, beer and spirits labels have become strategic weapons in brand storytelling and consumer persuasion. In South Africa, the label printing industry is experiencing a dramatic shake-up, driven by global innovation and the relentless pressure to meet local market demands.

Thomas Veenstra, owner of RAM Labels in Cape Town, South Africa, captures this evolution succinctly: ‘In this market, it’s the fine details that capture attention. Premium decoration transforms labels into high-impact visuals that bring brands to life, drawing consumers in at first glance.’

While South Africa’s labeling industry has traditionally lagged behind global standards, a wave of innovation is rapidly closing this gap. Modern trends are pushing converters and brands to embrace premium tactile finishes, such as uncoated papers, rich foils in gold and purple, and glow-in-the-dark inks. These aren’t just aesthetic enhancements; they’re strategic tools. As Veenstra explains, such elements heighten sensory experiences, reinforce authenticity and

combat counterfeiting.

‘A well-designed label doesn’t just enhance the bottle’s look; it builds trust, communicates value and defines a brand’s character,’ he says.

This push for innovation is mirrored in the wine labeling sector, where players like Rotolabel in Cape Town are driving transformative trends.

Grant Watson, national sales executive, highlights the rising demand for specialized materials. ‘Brands are elevating their products through unique substrates, often importing bespoke materials to gain a competitive edge,’ he notes. However, he warns that forecasting demand for these diverse material stocks remains a logistical challenge.

Beyond materials, the operational landscape is evolving rapidly. European regulations mandating the transition from 1D to 2D barcodes by 2027 have intensified time pressures.

Simultaneously, label aesthetics are undergoing a bold reinvention. While traditional designs retain their charm, a shift toward vibrant, contemporary visuals is gaining momentum. ‘Even established wineries are trading classic crests for modern designs that resonate with today’s consumers,’ Watson says.

“Sustainable materials and processes are no longer seen as premium options — they are becoming the norm”

The potential integration of RFID tags marks another frontier. As Wicus Maritz, managing executive at Rotolabel, points out, RFID technology could provide consumers rich insights into a product’s origin and journey. Yet, the high cost of these tags poses a challenge to widespread adoption.

Adding to the complexity is the influx of new designers in the market, bringing fresh perspectives but requiring education on the entire label lifecycle.

‘Designers need to understand how to balance creativity with practicality and cost-effectiveness,’ Maritz explains.

Housekeeping

In the household product packaging space, choosing the right label substrate and adhesive is crucial, not only for a brand’s image but also for enhancing recyclability.

The complexity of household product packaging lies in the variety of plastic containers used, including high-density polyethylene (HDPE), polypropylene (PP) and PET. Each material demands specific adhesives and label substrates to ensure compatibility and recyclability.

‘There’s a lot of misunderstanding in the marketplace about the correct materials and adhesives to use,’ Watson asserts. ‘This is where we step in to educate and guide brands. It’s not just about slapping a label on; it’s about ensuring that label doesn’t hinder the recycling process.’

Rotolabel is trialing UPM Raflatac’s New Wave adhesive, designed for paper-based labels that cleanly separate from containers during the recycling process. ‘New Wave allows the paper label to remove easily in plain water at just 40 deg C, leaving the PP or HDPE container uncontaminated and ready for recycling.’

Watson is optimistic when asked about the cost challenges of using sustainable adhesives. ‘Sustainable materials and processes are no longer seen as premium options — they are becoming the norm. The cost of the label is relatively insignificant compared to the overall packaging, so it’s really about educating brands to make informed choices,’ he says.

Rotolabel’s efforts extend beyond adhesives to post-consumer recycled (PCR) content in labeling. It was the first company in South Africa to introduce PCR content in labels for Woolworths’ baby shampoo range. ‘While incorporating PCR into labels is still in its infancy, it’s a critical step towards a more sustainable future. The challenge lies in maintaining consistent quality, especially with color variation in PCR materials, but the technology is advancing,’ he concludes.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.