Sato New Zealand invests in Mark Andy Performance Series P7 press

The company improved the label production time by up to 40 percent and doubled its run speed on unsupported film work.

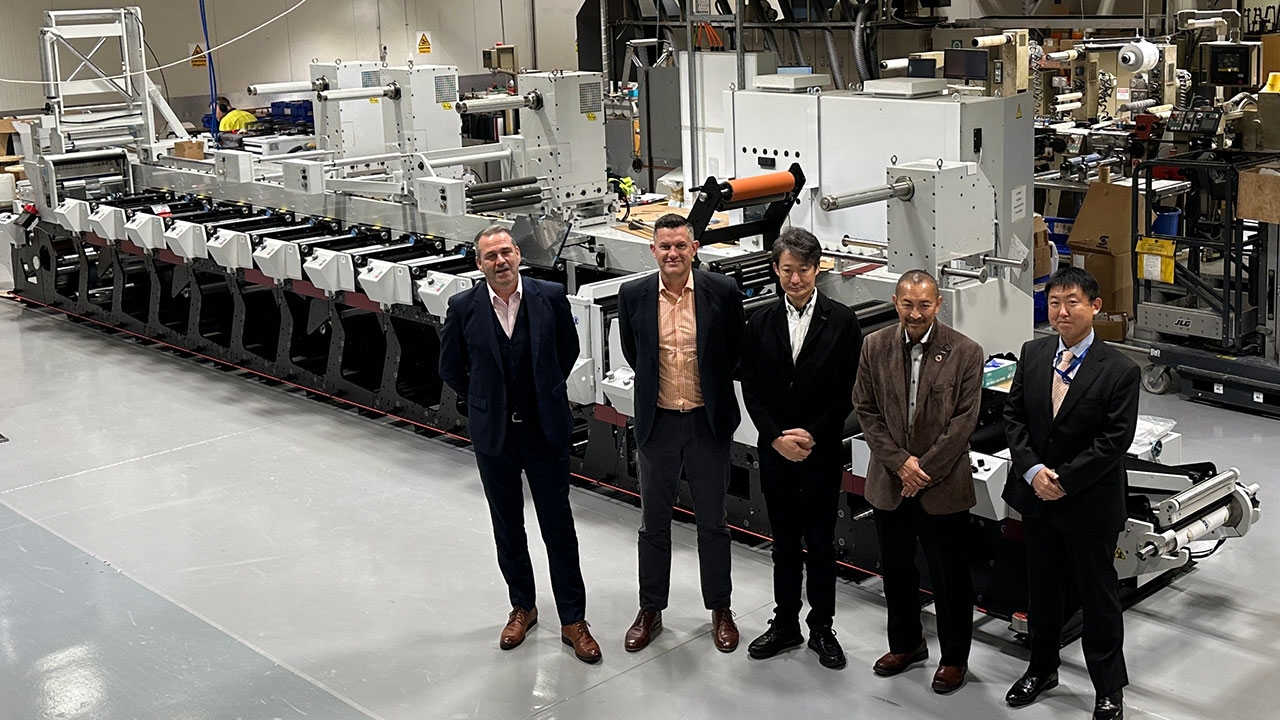

The New Zealand division of Sato, a global barcode and RFID technology company focusing on data capture and label printing, has invested in a Performance Series P7 flexo press, purchased and installed by Aldus Graphics, the regional distributor of Mark Andy equipment in Oceania.

Sato New Zealand was seeking a solution to revitalize its production capabilities, further motivated by a need to address the obsolescence of its equipment, which was reaching the end of its economic lifespan.

The inefficiencies in the company's operations led to the consideration of modern and advanced alternatives, which led the company to explore the capabilities of the Mark Andy Performance Series P7 flexo press.

'The implementation of the Mark Andy P7 involved a meticulously planned process initiated by the shipping of the equipment from the United States,' said Jurgen Gielen, general manager of Sato New Zealand. 'We encountered a challenge with shipping delays, which were efficiently managed in coordination with the operations manager and our freight forwarder. Upon arrival, the unloading and installation phase was expedited and completed impressively within a week.'

Sato conducted thorough print tests to ensure all units were correctly in register and auxiliary equipment was functioning optimally.

Given the Sato team's prior familiarity with Mark Andy presses, training two printers took just over three days. It was primarily focused on the new system's features and operations.

'The introduction of the Mark Andy Performance Series P7 has already manifested significant benefits in our operations, notably enhanced productivity, faster running speeds, reduced set-up times, and improved print register,' added Gielen.

These advancements have elevated Sato's print quality, ensuring greater consistency and amplifying its production capacity.

'As we continue integrating the new press into our workflow, we anticipate it evolving in tandem with our company's expanding needs, further optimizing our operational efficiency,' Gielen said.

The company has already noticed several improvements, with the self-adhesive label production now being between 30 and 40 percent faster on long-run jobs. Sato can also now run unsupported film, doubling the speeds achieved on the previous machine.

'Mark Andy Performance Series P7 presses are highly capable production tools with a wide substrate range and 305 meters per minute running speed with high-speed configuration. It is designed to drive profitability in a highly competitive industry and redefines workflow productivity through its simple design, efficient waste savings, and fast changeovers. I am very pleased that Sato New Zealand is already seeing the benefits of this modern equipment and achieving significant capacity improvements,' added Chris Bodger, national sales manager at Aldus Graphics.

'Our collaboration with Aldus Graphics has been a remarkably positive experience. From the initial demonstration to the installation and the post-purchase support, its team has demonstrated exceptional professionalism. We especially appreciate the ease and responsiveness in communication, which significantly contributed to the smooth integration of the new system into our operations,' concluded Gielen.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.