Fuya focuses on diversification

Recently the company introduced an ERP management system to help achieve steady growth through a strategy of diversification. Xiamen Fuya is located in the Special Economic Zone of the coastal city of Xiamen in Fujian Province.

Ms Ye Liling, founder and general manager of Xiamen Fuya, started out in the business forms printing industry in 1994. In 1999, she started working with her husband Fu Guohua to establish Xiamen Fuya with a clear focus on self-adhesive label printing.

‘At the beginning of our business, there were less than ten employees including me and my husband,’ recalls Ye Liling. Pushing through the initial difficulties, the wife and husband team were able to take advantage of the rapid growth of the whole label and packaging industry as China went through an industrial transformation. The company has now achieved ISO9001:2015 quality management certification, ISO14001:2015 environmental management certification and UL certification.

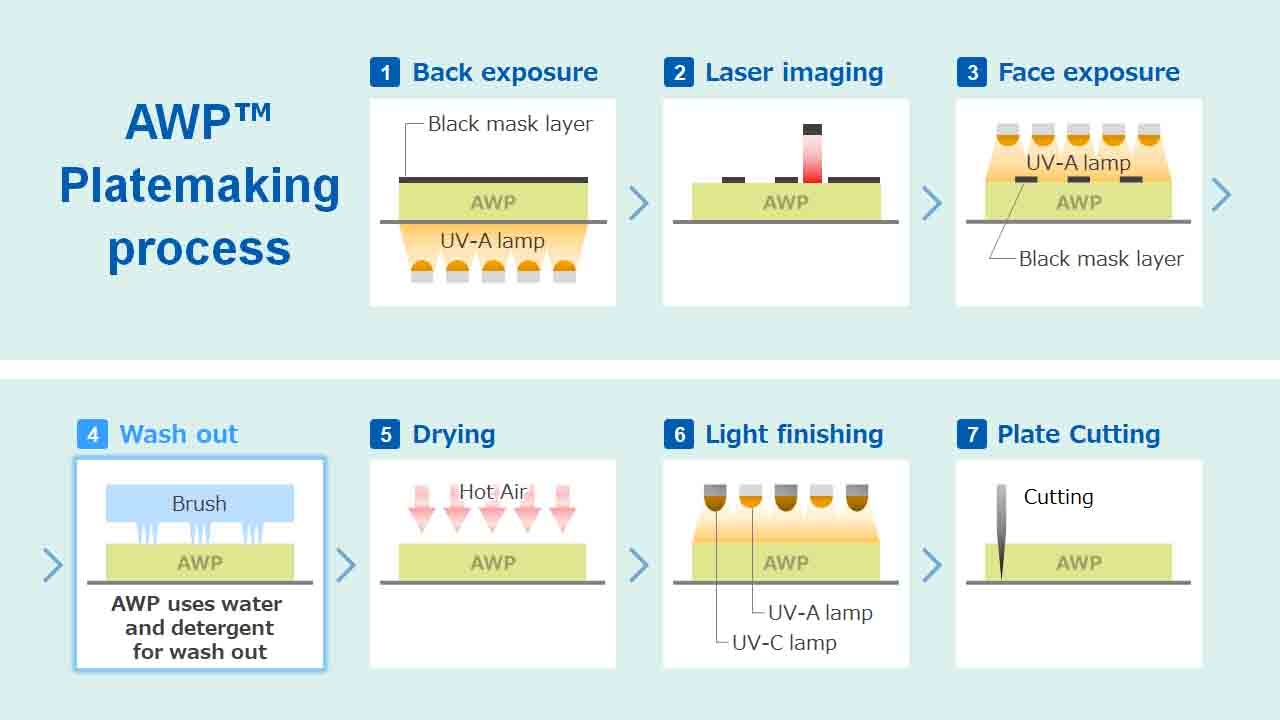

The original workshop built in 2001 and located at Guankou Town, Jimei District, Xiamen, was fully renovated in 2016. It has in-house platemaking and separate areas for conventional and digital printing, along with a post-press processing workshop. The company has a total production area of 4,000sqm and more than 70 employees and in 2020 total annual output reached 40 million Yuan (6m USD).

‘So from the beginning, Xiamen Fuya has adhered to its original aspiration of focusing on self-adhesive printing,’ says Ye Liling. ‘I love the self-adhesive printing industry, and I am full of interest in new materials, technology and equipment. Each time I go to a professional trade show, I want to invest in new equipment and new materials!’

Diversified development

Diversified development

Fu Guohua, general manager of Xiamen Fuya, says that diversification is a key strategic focus for the company, and its entire approach to specifying equipment, product development and management structure is designed with this end in mind.

Xiamen Fuya’s printing equipment includes a Qiangrun full rotary press, Jenki 8+1 full rotary press, Zonten 4-7 color intermittent offset rotary press, Konica Minolta 1060 single-sheet digital printing press, as well as Ribon and Vorey die-cutter, AVT and Luster inspection systems and Rhyguan post-press processing equipment.

At the end of December 2019, Xiamen Fuya invested in an HP Indigo 6900 digital press, and in March 2020 installed a Weigang 10-color unit-type flexo press. More recently, it invested in a Kurz digital hot stamping machine – a first in the Chinese market.

‘Our production equipment covers a variety of printing technologies including letterpress, offset, flexo and digital printing, which allows us to fulfil more than 90 percent of label printing orders on the market,’ says Fu Guohua.

Labels produced by Xiamen Fuya are widely used in the toiletries and cosmetics, pharmaceutical, health care, food and electronics industries, with household chemicals accounting for more than half of total business volume. ‘After years of endeavor, Xiamen Fuya has won wide recognition from the market by virtue of its high-quality products and professional service,’ says Fu Guohua. ‘Now we have a steady group of loyal customers.’

Looking to manage production, quality control and personnel more efficiently, Xiamen Fuya has invested in an ERP workflow management system from YLYprint, which has not only improved business management and operational efficiency, but also reduced operating costs.

Full-time personnel are dedicated to quality control using an in-house developed QC system which starts with intensive personnel assessment and training followed by an incentive system which rewards defect-free production. The effect of this is to make each individual responsible for quality control.

“Each time I go to a trade show, I want to invest in new equipment and new materials”

‘We are guided by the need to optimize production capacity, reduce wastage of labor and materials and improve overall competitiveness, so as to provide the best quality products and services for our customers,’ says Fu Guohua.

The Covid-19 epidemic of 2020 saw Fuya receiving a lot of label orders for hand sanitizers and disinfectants, and the company’s total business volume increased by 30-40 percent.

‘We understand that these increases are temporary,’ says Fu Guohua. ‘With the launch of the new coronavirus vaccines, the global epidemic will be gradually brought under control, and the label demands driven by Covid-19 will also gradually decrease. Label converters need to keep a sense of rational judgment and exploring how market and customers’ needs are shifting so as to achieve a steady growth.’

Increasing raw material prices and pressures for environmental protection have led the couple to consider the future development of the company.

On the one hand, the driver is always to optimize the company's production capacity, making best use of its blend of print technologies. The latest Weigang 10-color flexo press is mainly used for mass production orders; the HP Indigo 6900 is mainly for short-run, personalized, variable data labels; the Kurz digital hot stamping machine provides more possibilities for personalized decoration.

On the other hand, the goal is to continuously optimize the overall business model and exploit new business opportunities. At present, Xiamen Fuya is mainly focused on the local market within Fujian Province and some export label orders via agents. In 2014, Xiamen Fuya opened its flagship store on the Alibaba website, allowing it to accept small-run orders directly from online customers.

The future will be to attract more new customers by leveraging the new digital and in-line flexo press assets. ‘In the future, we will also consider moving into in-mold labels and flexible packaging,’ says Fu Guohua.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.