Linney invests in Focus Proflex 330SE hybrid press

UK packaging company invests in hybrid press to handle a growing percentage of short-run, digital full-colour label requirements.

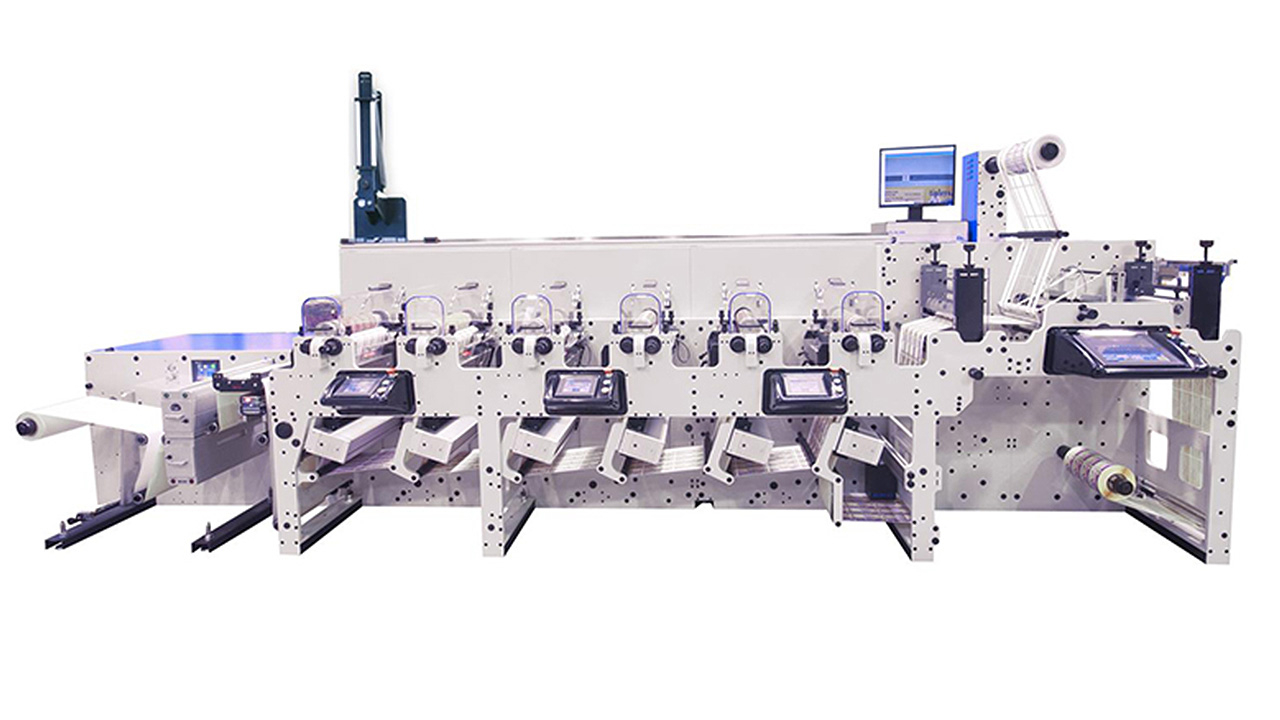

Linney, one of the UK’s largest independently owned print and packaging companies, has invested in the latest Focus Proflex 330SE hybrid press to handle a growing percentage of short-run, digital full-colour label requirements and higher-volume flexo jobs.

Having originally installed a 6-colour flexo press for label production from Focus Label Machinery several years ago, the company has recently invested in the latest Focus Proflex 330SE hybrid press.

Executive director Charles Linney commented: ‘Our Focus flexo press has been a great workhorse, giving us reliability and consistent quality across a range of different label types for all our medium and long run label jobs. In recent years, however, we have seen a steady increase in the requirement for short-run work, so we decided to incorporate digital inkjet capability to give us greater efficiency.

‘The Focus Proflex Hybrid really is a true hybrid press, in every sense of the word, successfully combining flexo, single-pass inkjet technology and in-line converting, giving us optimum flexibility.’

The Proflex SE Hybrid is a full-colour (CMYK) digital inkjet press with four in-line servo-driven flexo print heads and converting facilities. It is available with web widths of 250 mm and 330 mm. Die-cutting can be either full or semi-rotary. Both UV and LED drying systems are available.

Incorporating Konica Minolta's latest, high-quality piezo drop-on-demand inkjet heads, the Proflex Hybrid offers facilities for in-line flexo printing/coating, corona treatment, cold foil, laminating, varnishing and die cutting, either in roll-to-roll or roll-to-sheet applications.

The modular inkjet system is available in 149, 223 and 297mm wide versions, with running speeds of up to 50 m/min. In addition to process colours, a white option is also available, with LED pinning, for printing onto transparent or metallised substrates, aluminium foil or for overprinting dark background colours. The GIS software and RIP, with variable information and colour management system, are included in the overall package. There is no click charge and no mandatory service contract.

A wide range of substrates can be printed, including paper, PP, PE, carton board and aluminium foil, with no need to purchase specially coated materials for digital printing. For those few substrates that do benefit from pre-coating, this can be applied using a flexo print station supplied with either UV, LED or IR drying. In-line corona treatment is also available for surface treatment of filmic substrates.

The flexo printing and converting section of the press also enables high-speed four-colour, flexo production for longer runs and can re-register to pre-printed web, with accurate re-registration, at speeds of over 120 m/min.

James Thomas, head of sales and business development for Focus, commented: ‘For Focus, Linney represents a major UK PSP investing in our products and services. This says a lot about the Focus brand and quality of products designed and built with our customers’ businesses in mind. We are delighted to be part of Linney’s ongoing investments programs’

David Lee, sales director at Focus, added: ‘Linney is a very innovative and highly respected company. We are honoured and delighted that once again, it has selected Focus to be its trusted partner for this latest installation. The Proflex Hybrid model provides both flexo and high-resolution inkjet single-pass print technology, with an industrial performance, suitable for label and packaging manufacturers alike.

‘With increasing pressures from buyers to order lower quantity at more regular intervals, our hybrid technology offers an effective method of producing short and medium-run, digital print on affordable equipment, without click charges or obligatory service contracts.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.