Folding carton and flexpack enter Labelexpo

As the industry moves more into flexible packaging and folding cartons, Labelxpo Europe exhibitors already supply a wide range of products catering to those markets.

Edale FL5 carton press with in-line flatbed die cut-crease module

Labelexpo Europe 2025 will be the first in the event’s 25-year history to focus on folding cartons as well as labels and short-run flexible packaging.

Given how much print, converting and embellishment technology is shared across all package printing sectors, it is perhaps not surprising that over 25 percent of existing exhibitors at Labelexpo Europe 2025 have portfolios that reach across labels, flexible packaging and folding cartons.

FOLDING CARTONS

Inks and coatings

In the inks and coatings sector, suppliers to the folding carton industry include Sun Chemical, Flint Group, Eckhart, HuberGroup, INX, Paragon Inks, Toyo Inks and Zeller+Gmelin. GSE focuses on liquid ink logistics, where traceability is a key requirement.

Flexible packaging materials suppliers are recognizing the new mid‑web in-line technology as a distinct market sector and opportunity

These exhibitors span sheet-fed/rotary offset and flexo technologies across a range of chemistries, including UV and LED-UV, as well as water-based inks and coatings. The show also features a strong lineup of UV and LED-UV lamp technologies from companies such as GEW and Excelitas.

Barrier coatings are a key technology for both flexpack and folding cartons, and are well represented at Labelexpo Europe 2025 by companies such as Archroma Packaging Technologies and Triwill Group. Adhesives suppliers with specialist folding carton grades include Bostik and Eukalin.

Foiling and embellishment

Foiling also spans labels and folding cartons. Kurz, for example, is a key supplier to the folding carton sector, both for in-line cold foil application on sheet-fed presses and in off-line hot stamping configurations.

Pantec’s Cheetah W850/1060 rotary stamping technology is available for both in-line and off-line folding carton applications and is a strong performer in the tobacco packaging market.

Other foiling suppliers at Labelexpo Europe, spanning both sectors, include API, Univacco, and Gietz, with Leonardus demonstrating its holographic foils.

Digital embellishment is gaining increasing traction for both label and folding carton converters and this technology can be seen at Labelexpo Europe 2025 from suppliers like JetFX and Konica Minolta, which demonstrated its MGI AlphaJET single pass B1/B2 digital print and embellishment system at drupa.

Ancillary and consumables

Since wet glue labels remain the dominant technology for primary labels, Labelexpo Europe 2025 showcases suppliers of various ancillary technologies and consumables for offset presses.

These include suppliers like Continental showing offset blankets and Felix Boettcher displaying its offset pressroom chemicals.

In-line flexo coating units are standard equipment on offset presses specified for folding cartons, and the complete flexo ecosystem can be seen at Labelexpo Europe 2025. This includes varnishes, plates, anilox rolls, doctor blades, enclosed chambers, double-sided tapes, anilox cleaning systems and ink and varnish pump dispensers.

Inspection companies also span the three main package printing applications. Suppliers exhibiting at Labelexpo Europe include AVT and Luster Lightech, a Chinese AI-based inspection system developer. EyeC supplies the ProofRunner Carton 100 percent quality control system, which sits directly on the folder gluer.

Die-cutting/creasing

Die-cutting and tooling suppliers use Labelexpo to promote their label die-cutting plates and cylinders; however, these companies are also active in the folding carton market, particularly with male-female die sets for cutting and creasing on rotary flexo and offset presses. These exhibitors include Kocher + Beck, Wink, Sysco, Maxcess/Rotometrics and Lartec.

Laser die-cutting is an area of increasing importance at Labelexpo Europe, and laser cut/crease has also been a focus of development for the folding carton industry. Lang Laser, for example, has developed the Cartos Singular laser cutter, which allows for the production of folding carton samples, scalable up to full production runs. The Cartos system can also be used for intricate cutouts.

Among the new exhibitors is Technifold, whose retrofittable Technicrease cassette is designed to replace custom male and female creasing dies.

Pre-press

Automation of key pre-press processes, including preflight, imposition and color management, is common to all package printing processes. Both Esko and Hybrid Software specialize in full folding carton workflows, including structural design and 3D visualization. GMG offers its color-accurate prototype proofing system for folding cartons, while Hamilroad promotes its Belissima DMS screening technology for both litho and flexo applications.

Printing presses

Edale showcases its CartonLine folding carton press, demonstrating fully in-line print and converting of folding cartons. The press is configured with six LED-UV flexo units, a rail-mounted turnbar, lamination and Edale’s EZ foil unit with an in-line flatbed die-cutter.

Over 25 percent of existing exhibitors at Labelexpo Europe 2025 have portfolios that reach across labels, flexible packaging and folding cartons

Although this is currently the only folding carton press confirmed for the event, a wide range of presses at the show can be configured for in-line folding carton production. This is particularly the case for the ‘mid-web’ (26in/670mm) presses displayed at the show by Nilpeter, Mark Andy, Lombardi and Chinese supplier Spande.

Omet has a long history of building dedicated folding carton presses based around its Varyflex platform.

Rotatek demonstrates a print unit from its Universal 850 press configurable for folding cartons, along with an AI project that models ink-water balance on offset press platforms.

Mark Andy recently announced that its MAPP division, which supplies consumables and plate-making equipment to packaging converters, will now add folding carton consumables.

There is also great potential for digital printing of folding cartons among exhibitors. Xeikon has demonstrated digital print and embellishment of folding cartons at previous Labelexpo shows, while HP Indigo has a portfolio of digital sheet-fed solutions. Fujifilm has the JetPress 750 sheet-fed press configured for folding carton production.

FLEXIBLE PACKAGING

While folding cartons are new to Labelexpo, flexible packaging has been gathering momentum at the show for at least the last decade. Increasing numbers of label converters are adding flexpack to their portfolios, and wide-web flexpack converters are visiting Labelexpo to meet co-suppliers and to investigate short-run options using in-line or digital technology.

Because conventional flexible packaging presses primarily use flexographic technology, whether in-line or central impression (CI), all suppliers of flexo pre-press, plates and platemaking, inks and varnishes, anilox and doctor blades are relevant to flexible packaging converters.

The growth in the use of LED-UV curing systems is highly relevant to in-line printing of flexible packaging, as they significantly reduce the amount of heat transferred to the web compared to a standard arcUV lamp system.

GEW demonstrates its water-cooled LED LeoLED2 and E4C combination, which the company recommends for flexible package printing, although in some situations, GEW says its air-cooled AeroLED2 and E2C are sufficient

Surface treatment is an absolute must for the flexible packaging converter working primarily with filmic substrates, and IEEC and Vetaphone are among the suppliers demonstrating these systems.

Label converters moving are finding profitable niches in short-run, value-added flexible packaging work. However, what is considered a short run for flexpack is still a long run in labels, and may justify investment in the kinds of automated, non-stop unwinds and rewinds demonstrated by Martin Automatic.

Inks and varnishes

Where FMCG labels are mostly affixed to containers with a functional barrier against ink migration, flexible packaging is the direct container of the edible or drinkable contents. Apart from pouch materials which incorporate an aluminium barrier layer, this makes the ink and coatings choice a more critical factor. UV or LED-UV inks need to be specified as low-migration and often need to be encapsulated in a water-based coating. In other cases, brands may specify the use of water-based or solvent inks.

Among ink suppliers that can advise on these choices are Flint Group, Huber Group, Pulse, Toyo Ink Europe, Sun Chemical, VPF Ink Technologies, Frimpeks, Siegwerk, Zeller+Gmelin and Super Color.

Along with inks, barrier coatings and packaging adhesives are other key topics of interest to flexible packaging converters. At Labelexpo, first-time exhibitor Archroma highlights its adhesives for flexible packaging while RK Print Coat Instruments demonstrates R&D and QC test equipment for coating, inks, adhesives and barrier coatings.

MIS and workflow tools

As noted for folding cartons, MIS suppliers to the labels industry generally also have modules covering other packaging types, including flexible packaging.

Conics demonstrates an automated production workflow and planning tool for flexible packaging producers; Sistrade shows its dedicated flexible packaging MIS module, and Theurer showcases its C3 Flexible Packaging & Converting, which is the pre-configured business template for flexible packaging, film manufacturing and converting within theurer.com C3. Design, 3D visualization and workflow tools specific to flexible packaging can be viewed on the Esko and Hybrid Software stands.

Digital presses

While HP has long dominated the digital flexible packaging sector (although the company does not show the 200K at Labelexpo Europe), water-based inkjet is increasingly the technology of choice for digital flexible packaging.

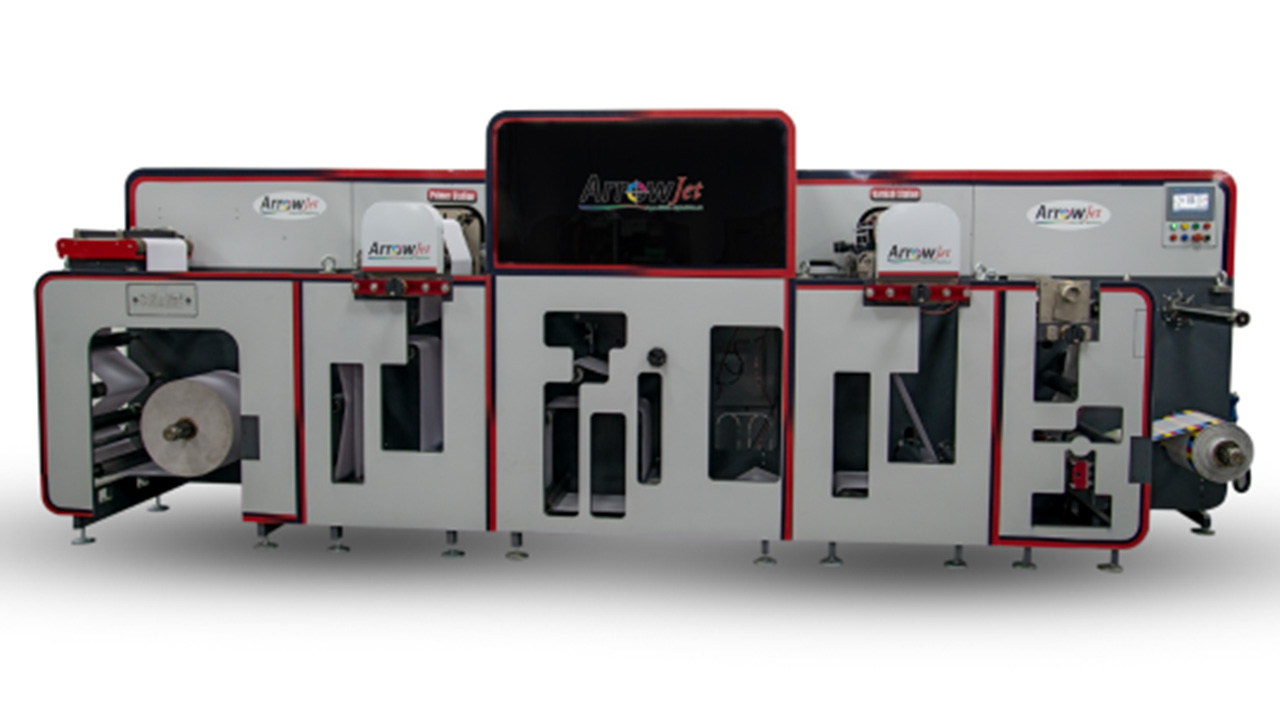

Arrow Systems shows its ArrowJet Hybrid Pro M printing on UPM Confidio barrier papers, along with sample pouches printed on the ArrowJet Aqua 800.

Screen promotes its Truepress PAC 520P water-based inkjet press for paper-based packaging. The company also shows samples from its Truepress PAC 830F water-based inkjet press for flexible packaging films.

But WB is not the only digital process on view at Labelexpo. Valloy launches the toner-based Rollio Xpress, a compact 330mm (13in)-wide 4-color press which can print on thin BOPP, aluminum foil, paper or composite film at resolutions of 1,200 x 2,400 DPI.

Durst demonstrates its latest LED-UV inkjet Tau press, specified for surface printing on barrier lamitubes and pouches. The press uses low-migration LED-UV inks.

In-line conventional

Mid-web presses (26-30in / 670-800mm) are ideally suited to the format sizes of flexible packaging and are well represented at the show. The ability to hold register on thin and extensible substrates is a must, along with ‘soft’ tension control systems.

Mid-web machines at the show capable of handling flexible packaging films include the Spande AC, Nilpeter FA-26, Mark Andy Performance Series S9, Omet X7 and Lombardi Invicta i1. Bobst and MPS both promote their mid-web presses configured for flexible packaging, although with no presses at the show. Rotatek shows a print unit from its Universal 850 rotary offset press, while Bengraphic demonstrates its F8-650 press specified for flexible packaging, with heavy-duty dual servo-driven print and converting units.

Multitec and Weigang both say their presses are capable of handling flexpack materials, with the Weigang ZJR series specified to handle 12 micron films.

Although there are no CI or gravure flexible packaging presses at the show, several suppliers will promote this technology to label converters looking to ramp up production volumes. Comexi promotes its F4 CI press, designed for shorter runs and available in the ‘mid-web’ 670 and 800mm-wide formats. This is an example of how CI and in-line presses are converging on this width.

A particularly interesting CI development is Giave’s Gialux UV LED CI press. Because it does not require a drying tunnel, the press is compact and eliminates the use of solvents.

Embellishment

One of the key advantages of in-line printing of flexible packaging is the ability to add decoration processes on a modular basis, in exactly the same way as on a label press.

Cold foil is one value-added decoration process for flexible packaging. Pantec demonstrates a range of pouch and embellishment possibilities, including textured foiling/embossing and micro‑embossing using its Rhino S410 embellishment equipment.

A range of exhibitors, including Kurz and Lemmaco, demonstrate cold foil and adhesive systems suitable for application to flexible packaging materials.

Digital embellishment is a key trend in both labels and flexible packaging. At the show, JetFX launches the Solo FlexPack, which extends digital embellishment to flexible packaging. With FDA-compliant embellishments and optional UV or eBeam curing, it allows food-safe gloss, matte and embossed finishes directly in-line on pouches, films, and wraps. The unit can be installed in-line on a press, on a laminator or on an off-line finishing machine.

Cutting and perforating tooling

Berhalter Swiss demonstrates die-cutting systems tooled for a wide range of flexible packaging applications, including lidding materials, as does Schobertechnologies, which brings to the show cutting, perforation and punching tools for flexible packaging.

Substrates

Flexible packaging materials suppliers are recognizing the new mid-web in-line technology as a distinct market sector and opportunity, which tends to require more of a ‘label-supply’ mentality of smaller and more frequent deliveries, even slit to width.

Barrier coatings are a key technology for both flexpack and folding cartons and are well represented at Labelexpo Europe 2025

Synthogra has led the way in tailoring its inventory to the requirements of the emerging mid-web in-line market. The company shows a high-barrier, mono-material film for flexible packaging in PE and PP, suitable for pouches and other applications.

GMerix showcases its custom-coated PET and specialty films for flexible packaging applications. The company also promotes contract slitting and rewinding services for flexible packaging films, toll coating and R&D support.

Nobelus is releasing a line of eight films in a variety of finishes and material types compatible with different flexible packaging structures. For gloss and matte, the company offers its Platinum OPP films and sustainable EcoElement CLS films, which can be used for compostable packaging. Toray International demonstrates its mono-material and retortable films.

Slitting and rewinding

While materials suppliers transition to a new supply model for short-run production, converters are investing in warehousing space to hold stock and slitters to process master rolls. There is also a requirement for slitting mid-web rolls off-line, and Ashe demonstrates its 800mm-wide Solitaire duplex slitter tailored to mid-web in-line flexible packaging presses.

Pouch making

Many label converters who have moved into flexible package printing have taken the next step up the value chain by taking pouch making in-house. At Labelexpo, Galaxy Packtech showcases its GS 24 Plus 200 pouch-making machine, designed for the production of stand-up pouches, three-side seal pouches and zipper pouches at speeds of up to 200 cycles per minute with a working web width of 200-1,200mm. It is fully compatible with recyclable mono-materials.

Shrink sleeves = flexibles?

It is interesting to note that for the wide-web converter, shrink sleeve labels fall under the category of flexible packaging, along with stretch sleeves and all other forms of unsupported filmic materials. For these converters, there is a wealth of shrink sleeve suppliers to visit at Labelexpo Europe 2025, demonstrating everything from inks, coatings and materials to seaming and inspection machines.

Exhibitors in this segment include DCM Group with its Sleeve3 entry-level forming, perforating, hotmelt application and inspection system; Karlville shows its latest K3 Plus Seamer, which can be configured as a stand-alone unit or with turrets; the Polly Automatic PA-series shrink sleeve seaming machine; Eckart metallic inks for both LED/UV and solvent gravure systems; and sustainable shrink sleeve materials from Taghleef, Klockner Pentaplast, Innovia and Sleevemaker by Maytech.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.