RFID Masterclass offers key insights

The Labelexpo Americas RFID Masterclass provided label converters with a key understanding of both converting challenges and new business opportunities.

The RFID Masterclass at Labelexpo Americas 2024 provided label and packaging converters with a comprehensive insight into the technology, along with an understanding of the challenges and opportunities for building new business.

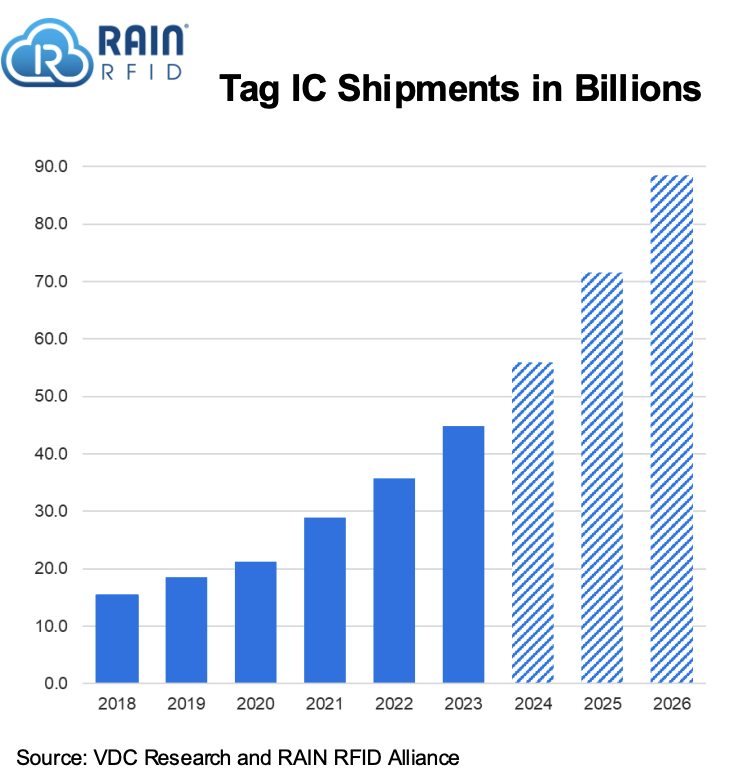

David Weinhammer, senior global RFID product manager at Zebra Technologies, opened the masterclass by explaining how RFID applications have exploded over the last few years. In 2023, 45 billion tags were sold. The end-use market is growing at a rate of 25 percent year over year, meaning that 90 billion tags will be sold in 2027 alone.

Dr Vlad Sljapic, COO Graphimecc explained, ‘RFID is at the core of the modern manufacturing and retail ecosystem: global traceability, the circular economy, tracking carbon footprint, brand protection and regulatory compliance.’

This provides unique opportunities for label converters, but it does require an in-depth understanding of how RFID systems perform, as well as the challenges of converting and how to specify deliverable RFID systems to customers.

Perfect placement

Gary Stegall, an RFID expert at Avery Dennison, emphasized the importance of label converters fully understanding how RFID tags will be used.

He explained how metal surfaces, including foil, and the presence of liquids, can impact the read range of RFID antennae.

‘Placement is a critical factor,’ Stegall says. ‘Walmart, for example, has metal shelving, and a lot of brands want to put the RFID tag on the bottom of the box because it is out of sight. That metal shelf causes the radio signal to bounce off. The antenna never gets a chance to grab the energy from that radio signal and wake up the tag.’

Liquids present another problem, which will likely be exacerbated as Walmart and other retailers move RFID into general merchandise.

‘A regular RFID tag put behind the prime label right in the middle of a bottle of antifreeze just doesn’t work,’ says Stegall. ‘There’s too much water in there.’

Stegall mentioned that Avery Dennison has successfully placed a tag in the middle of a prime label for a motor oil. ‘It’s the makeup of some of the motor oils. I found that (tags) work on kerosene. It’s just interesting that on certain products, liquid products, it will work. However, it will not work on anything water-based. What about shampoo? Is it going to work? We hear rumblings and rumors that the next thing that’s going to roll out, the next phase is going to be health and beauty and over-the-counter drugs at Walmart.’

Stegall says it is often possible to find a workable location for the RFID tag if the brand owner is flexible.

‘I’ve seen somebody with a car wash liquid where they’ve made a place on their prime label, so the RFID antenna flags off the bottle a little bit, but it still looks like it’s part of the prime label,’ he says.

‘Now that it’s off the bottle a little bit, now I can read it with a scanner. And Walmart approved it.’

Stegall says Walmart is happy to work with converters to find solutions. ‘They want to work with you, and they want to hear what you have to offer. And they are going to give you ideas.

It’s interesting that on certain products, liquid products, RFID will work. But anything water-based, it will not work on

For example, can you get a tag above the fi ll line on that bottle? Can you put it on the cap, on the trigger assembly? Is it possible? That’s not always possible. It’s very hard sometimes on the production line to get an RFID tag on a trigger assembly.’

In some cases, a hang tag-type assembly may be the answer.

‘Because it hangs down over the neck of the cap, that leaves possibly enough air space between the tag antenna and the liquid, so now it can be read.’

QC issues

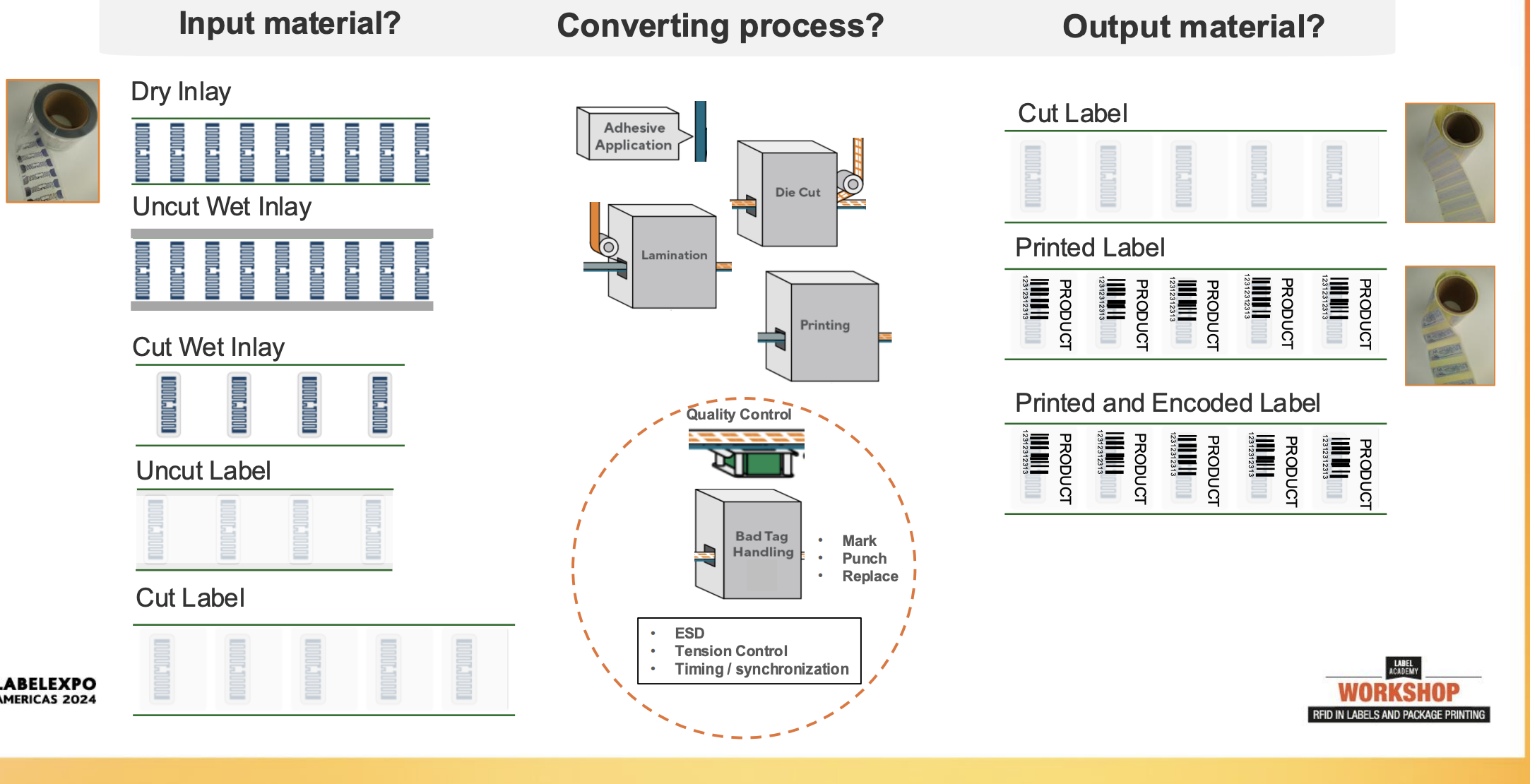

Teemu Ainasoja, sales director from Voyantic, addressed the issue of quality control during RFID production.

Traditional label inspection is based on cameras. However, in RFID, you cannot visually see whether a tag is defective. This needs specialized RF equipment. There also needs to be a way of marking and possibly removing bad tags.

A common practice for tags that fail the QC test is to print a void mark on the labels, or to have imperfect labels punched, ‘to somehow physically damage the label’, so that it is clear it will not accidentally end up in use.

During initial conversations with the customer, it is essential to specify whether 100 percent good RFID labels are required or if the widespread benchmark of 1 percent scrap is acceptable.

Explains Ainasoja, ‘Some customers in the medical field may require 100 percent quality, which means that if there is a failing tag, you need to either stop the line, replace a failing tag with a good one, or do post-processing with this kind of replacement or cutting procedure. So quality control and figuring out what will be done for the failing tags are the biggest changes when you move from traditional printed labels to RFID labels.’

Label converters, with their knowledge of films, face stocks and adhesives are in a unique position to deliver RFID into a wide range of end products

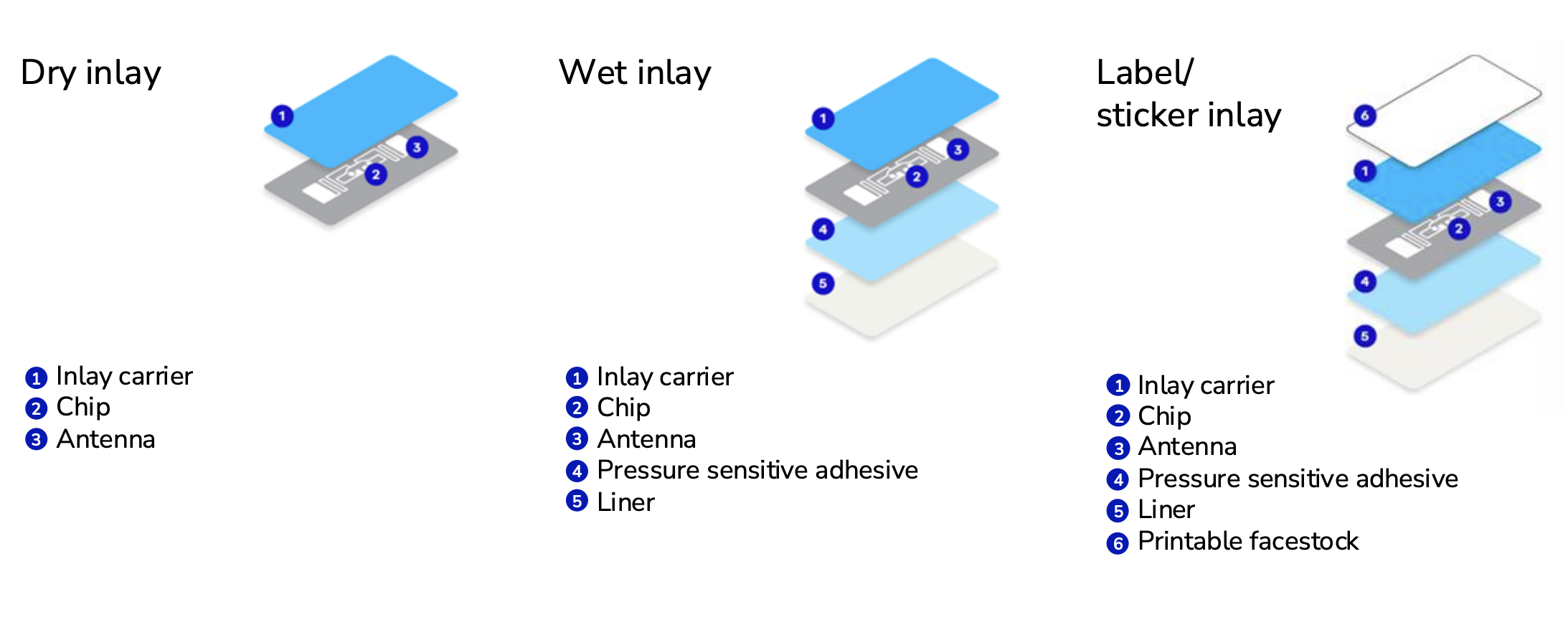

Ainasoja went on to outline other key converting challenges: ‘There are a couple of other things to think about, especially when you work with dry inlays, when there is no material on top of the (tag). They are then sensitive to ESD (electrostatic discharge), so ESD protection is essential.

‘Tension control is another one, again, especially for dry inlays,’ Ainasoja continues. ‘If the roll is too tight, the pressure on the IC (integrated circuit) can damage the connection between the integrated circuit and the antenna. Similarly, if the roll is too loose, it can start slipping and scrape off the ICs on the inlays.’

Die-cutting also presents challenges: ‘Timing synchronization is something else to watch out for. The dry inlays only appear to be continuous material when, in fact, it is intermittent. So, if the die-cut is not synchronized well, or the inlay insertion is not synchronized well, you can very quickly damage a lot of inlays by cutting the antenna. So, your machinery needs to synchronize things so that you don’t cut the antenna, but you cut in between.

‘The same with the insertion. The brand customer needs the label to be correctly placed, so the inlays should be in the right position inside the label. This again means that the timing and synchronization of the inlay insertion is critical.’

RFID specification

Voyantic’s Ainasoja explained that label converters need to tie down specifications and expectations with their customers before committing to production.

There are two key aspects to correctly specify RFID labels: system design and production quality control. Converters should clarify how the RFID labels will be deployed in practice and ask what kind of read ranges and reading angles will the RFID label be required to provide. For example, in applications where items are passing through a gate scanner, RFID tags with a very short read range will fail to scan.

Production QC covers how the label converter’s production department will create consistently performing labels across potentially millions of pieces. In technical terms, we are looking at tag sensitivity, or how much power a reader must provide to ‘wake up’ a tag.

‘There is some variation in any mass production process, and that applies to RFID also. The key is to produce labels within tolerance of the overall target RFID system,’ says Ainasoja.

‘Dead tags are easy to find. The challenge lies in finding live tags that are outside the read range tolerance for a particular application. The better, or the narrower, your variance is, the less waste is produced, and you keep your yield high. As mentioned, good and bad tags cannot be visually verified unless there is something obvious, like a cut antenna. Typical damage cannot really be seen, even under a microscope.’

One of the most common reasons for variation in performance is micro-fractures on the conductive glue between the connector tags in the IC and the antenna.

Ainasoja says: ‘You can only detect through the RF that the connection is good. Therefore, the readability of the tag is good. This is what the quality control system does.’

In most cases, there are no standards or criteria for setting the pass-fail limits or what kind of variance is acceptable.

‘How far from the middle point should my acceptance criteria be? That’s pretty much always the discussion with the customer: “This would be my normal yield, I propose this to be the cut-off limit”. And then if that’s good for the customer, you’re good,’ Ainasoja says. ‘If the customer requires better performance, then it’s always a discussion, because now my yield probably decreases. It turns into a pricing discussion. The discussion of the quality criteria, I think, is becoming more and more important when you discuss with label buyers.’

Conclusion

Today, RFID is a reliable, cost-effective technology. It provides retailers and brands with significant improvements to their inventory accuracy offering additional tertiary benefits, including supply chain transparency, brand protection and customer interaction.

Further, as Graphimecc’s Sljapic points out, ‘this is not just about the big retail groups who have been very public with their mandates. Many mid-size and smaller size companies are looking at RFID, not only to make their own processes more efficient, but because consumers now expect a higher level of communication and information about the products that they buy.

‘Label converters, with their knowledge of films, face stocks and adhesives, are in a unique position to deliver RFID into a wide range of end products,’ he says. ‘Understanding RFID technology and focusing on quality will be key differentiators, making converters better able to support their customers on the RFID journey.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.