Labelexpo Europe 2025: Finishing and converting

Automation, digital technology and laser systems drive finishing innovation.

The finishing and embellishment sector demonstrated remarkable innovation at Labelexpo Europe 2025, as converters seek technologies that combine automation, flexibility and premium aesthetic capabilities to meet evolving market demands.

Throughout the exhibition halls, suppliers showcased systems designed to address critical industry pressures: labor shortages, demand for shorter runs with faster turnaround times, and brand owners’ increasing requirements for distinctive, high-end finishing. The response has been a wave of automated, digitally enabled finishing equipment that reduces manual intervention while expanding creative possibilities.

Automation reduces operator dependency

The drive toward automation dominated finishing equipment demonstrations, with suppliers introducing systems that minimize operator involvement while maximizing productivity.

‘The overarching trend is to bring much more automation to machine processes to help operators and business owners achieve smooth operations,’ explains Pedro Teixeira, managing director at Lemorau. ‘What we are exhibiting here at the show demonstrates machines that do the job while automation allows the operator to simply supervise the machine operation.’

The Portuguese manufacturer emphasized that its approach focuses on making operators’ jobs easier, regardless of their skill level. By implementing software that automates processes, minimizes waste, and reduces setup time, Lemorau aims to support converters who struggle to find highly skilled personnel.

Automated turret rewinders emerged as a focal point for this automation push. Grafotronic unveiled the Infinity, a fully automated turret rewinder powered by Serame, designed to eliminate downtime during roll changes.

GM presented its semi-automatic turret with zero-waste job changeover capabilities, reducing changeover time from approximately 30 seconds to just five seconds. The system automatically reads barcodes to manage various jobs and includes automatic registration to correct cutting positions in real-time.

“Anything you can do to reduce the number of operators needed in the print shop is what’s driving the trend today”

‘It’s clear that fewer and fewer people are available to operate the presses in the print shop,’ notes Uffe Nielsen, managing director at GM. ‘People are looking for affordable ways to make production more efficient. Anything you can do to reduce the number of operators needed in the print shop.’

Nielsen emphasized that the challenge varies by region, with some markets experiencing more acute labor shortages. During a recent business tour in Japan, he observed that labor availability has become a critical issue, with converters actively seeking automation technologies to maintain production capacity.

Bar Graphic Machinery launched the BGM Elite 550iSR, a 22-inch finishing system incorporating GPS gear positioning technology that enables operators to load master rolls with self‑alignment, requiring no operator intervention. The system features constant air pressure technology and integral roll lifting capabilities.

Ashe Converting Equipment introduced its Opal Series ALCL, featuring a new autoset glueless four-spindle turret rewinder that sets itself automatically and requires no tooling change when adjusting core size. The machine runs at a guaranteed continuous production speed of 250m/min.

‘The new Opal Series ALCL brings converters more potential applications thanks to its wider width and quick set, and is 20 percent more efficient,’ comments Matthew Godbold, sales director for wide web machinery at Ashe Converting Equipment.

‘It optimizes productivity and efficiency with better throughput and fewer skills required by an operator to set the machine.’

Lemorau showcased its Smart-L Premium, equipped with next‑generation software developed in-house. The unified platform enables automatic initial positioning of tools, fast register setup and barcode scanning for tool recognition, drastically reducing setup times and material waste.

‘Lemorau is committed to creating intuitive, high-performance technology that simplifies complexity and delivers measurable value to our customers,’ comments Natália Lopes, part of the international sales team at Lemorau.

Digital embellishment expands creativity

Digital embellishment technologies represented one of the most significant trends at the show, offering converters the ability to add premium finishing effects without traditional tooling requirements. This shift eliminates substantial upfront investments in screens, dies and foil tooling while providing the flexibility to change designs instantly.

The rapid adoption of digital embellishment reflects a fundamental transformation in how the industry views inkjet technology. Digital inkjet is now seen as a manufacturing method, not just a printing process.

Printbars are being increasingly integrated into new machine configurations or retrofitted onto existing presses, enabling printers to meet the growing demand for label embellishments with greater efficiency and precision, without the need to replace entire systems.

Embellishments such as varnish, foil and raised textures are strongly associated with premium packaging. These features not only enhance the visual appeal of goods but also create a tactile experience that reinforces brand value. In sectors such as wine, spirits and luxury goods, embellishment of labels and packaging is often a key differentiator.

Digital embellishment is no longer a nice-to-have but is now a must-have feature for many original equipment manufacturers.

‘What’s driving it this year is digital embellishment,’ GM’s Nielsen explains. ‘We are showing some amazing stuff with digital varnish and digital foil, and that’s really helping in the print shops, because doing that before would require a specialist in screen printing. And these are the dinosaurs. They are hard to get. So having something where you can load a PDF and do the same amazing artwork, that’s really a trigger.’

GM featured its digital embellishment and foiling unit designed specifically for wine and spirits labels. The compact 1.6-meter frame fits into existing presses as a retrofit or new line, enabling short-run production with ease of use. Visitors witnessed the machine producing labels with complex foiling and varnish effects.

Cartes showcased its proprietary Jet D-Screen technology across multiple machines, combining digital embellishment capabilities with laser converting systems. The technology creates multi-layer effects, spot coating, complex tactile raised volumes, Braille printing, detailed foiling and metallic doming transfer.

‘Visitors particularly recognized Cartes for its ability to combine digital finishing with patented laser technology and modular platforms,’ comments Virgilio Micale, global sales manager at Cartes. ‘These are the pillars that allow our customers to differentiate in the marketplace while optimizing efficiency.’

‘The level of engagement we experienced in Barcelona exceeded expectations and confirms that converters worldwide are seeking approaches that deliver measurable production value alongside precision, speed and flexibility,’ states Enrica Lodi, chief marketing officer at Cartes.

Actega featured live demonstrations of EcoLeaf, its on-demand metallization technology, configured with a Gallus One digital press. Considered the new standard in sustainable metallic label embellishment, on-demand metallization helps converters and brand owners reduce their carbon footprint while delivering eye-catching labels and packaging designs.

‘One kilogram of EcoLeaf flakes replaces 3,000kg of foil. As industry innovators, this is a carbon footprint reduction that we cannot ignore,’ comments Marco Van Hooff, chief commercial officer at Reynders Label Printing. ‘Our on-demand metallization system, called S-Sential, is a true game-changer. It’s not just the carbon dioxide and waste reduction, such as eliminating the PET carrier film, that makes S-Sential compelling. It’s also the quick turnarounds achievable and the creative possibilities to use shiny metallization to differentiate your products.’

“One kg of EcoLeaf flakes replaces 3,000kg of foil. As industry innovators, this is a carbon footprint reduction that we cannot ignore”

Actega also introduced Signite applicator technology, making its Labelexpo Europe debut. This decoration for glass, PET and aluminum containers delivers approximately 30 percent lower Global Warming Potential compared to similarly sized pressure‑sensitive labels or shrink sleeves.

LemuGroup presented digital finishing equipment featuring an inkjet module for high-volume varnish application. The Mi 350 Digital Inkjet applies varnish in large volumes with maximum precision, eliminating varnish waste and requiring no tooling, screens or plates.

JetFx displayed its full suite of embellishment systems, including Solo, Solo FlexPack and Fusion, designed for seamless integration onto existing web presses, creating a single-pass workflow.

Brotech showcased its iDM800 digital embellishment system, capable of jetting white, digital foil and varnish, with capabilities for imaging Braille and adding textures, metallic and gloss effects.

Prati presented for the first time its DigiFast20000 in a high‑performance configuration, expanding its portfolio beyond narrow web to mid-web with capabilities for finishing all digitally printed jobs within the 760mm range with thicknesses from 12 to 450 microns. The machine handles flexible packaging, pouches, sleeves, labels and cartons, with finishing processes including spot white printing, protective UV or water-based varnish and digital embellishment.

‘If the end user wants to highlight their uniqueness and stand out in the market, now they can do so through finishing, adding extra value to their products,’ the company stated.

Xaar showcased how its printhead technology enables digital embellishment across multiple applications. The company’s Versatex Printbar, powered by Nitrox printheads, allows brands to incorporate high-opacity white, intricate textures, varnish effects and digital cold foiling. The Versatex’s High Creativity mode enables the simultaneous application of multiple textures and digital embellishments between 15 and 100 microns in one pass.

With the ability to jet three varnish effects at once, it eliminates the need for multiple substrate passes, improving production efficiency while reducing energy consumption and costs. At the Brotech stand, Xaar’s 2002 printhead was showcased within its varnish embellishment module, chosen for its superior productivity and versatility.

Laser technology advances flexibility

Laser die-cutting technology emerged as a critical innovation for converters seeking flexibility and waste reduction, with multiple suppliers showcasing advanced systems designed for high-mix, short-run production.

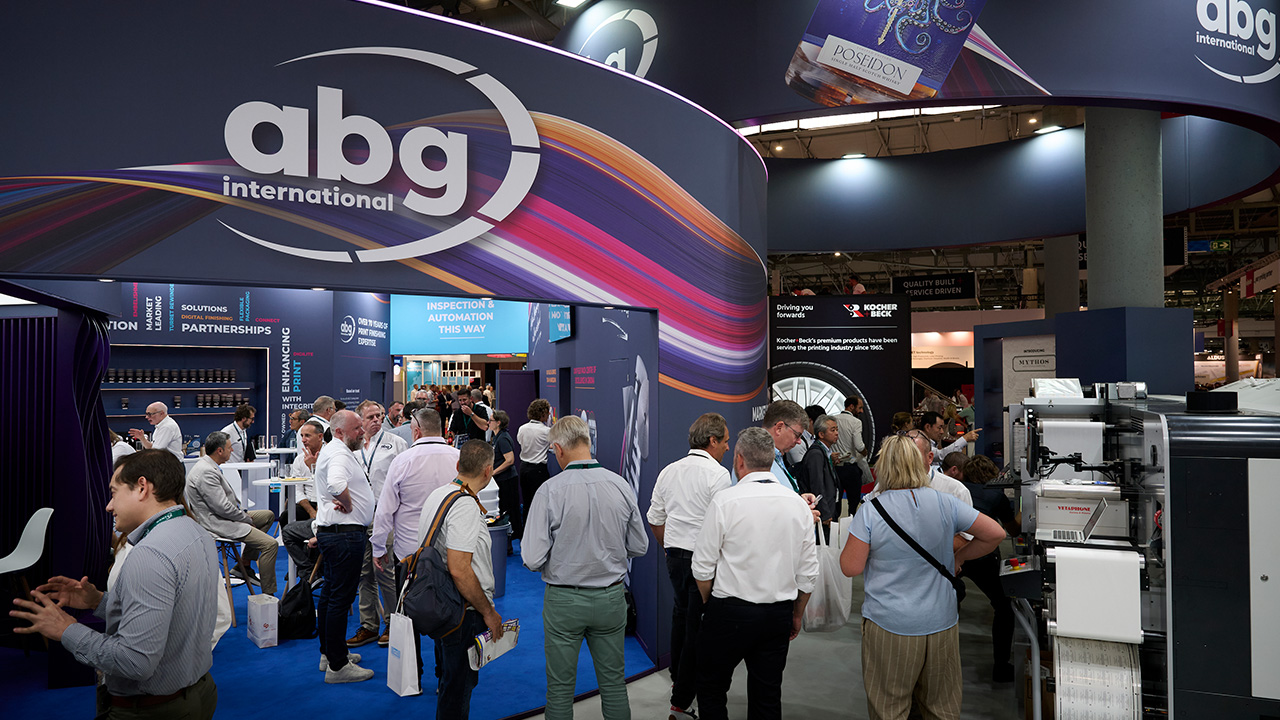

ABG’s DigiLase Duo proved to be a standout attraction, securing multiple sales at the show. By incorporating two independent laser light sources instead of one, the system achieves speeds up to twice that of a single-laser unit. A significant innovation within the system is Repeat Flow, which enables the automated switching of die lines within each web repeat, eliminating waste and requiring no operator input.

‘The DigiLase Duo is the result of listening to our customers and pushing the boundaries of what’s possible with digital laser cutting and in-house software development,’ notes Mark Norman, technical director at ABG. ‘By introducing dual independent lasers, we’ve been able to deliver enhanced speed, flexibility and reliability, while also helping customers minimize waste.’

GM’s laser technology attracted consistent crowds throughout the show, particularly for its ability to handle extremely short runs. The system demonstrated zero-waste job changeover and ease of operation, with the machine changing jobs continuously.

‘There’s a crowd around this laser all the time, especially for super short runs where you can stack 100 jobs in one roll,’ Nielsen observes. ‘The laser team is constantly busy answering questions about how the technology works.’

Grafotronic unveiled its next-generation Sci-Fi Laser, a fully modular laser finishing system available in roll-to-roll, roll-to-parts or hybrid versions. The company showcased more than 10 cutting-edge machines at Labelexpo Europe 2025.

Cartes featured its GE362WL-Dual, described as the fastest laser converting system developed by the company, equipped with patented Invisible Laser Cutting and lifetime unlimited laser source technology.

DPR Group showcased the Taurus X2 laser die-cutter, which features dual cutting heads generating 700 watts of laser power and can handle rolls up to 800mm in diameter.

Anytron promoted an upgraded Any-Cut for laser cutting, lamination and matrix removal, integrated with the company’s new automation software featuring hot folder-based job import, auto-nesting and auto-contouring.

Premium embellishment

The push toward premium, high-end finishing has become a defining characteristic of the label market, with converters investing in embellishment capabilities to meet brand owners’ differentiation requirements.

‘This industry has been growing in the embellishment area,’ explains Virgilio Micale of Cartes. ‘Customers are continually raising the bar higher and higher, and the range of products being offered continues to diversify. I believe the companies that are following this path are having success and will continue to succeed.’

Gietz unveiled a premium spirit label design that demonstrates the capabilities of its Rofo 450 ECO hot foil stamping unit through a sophisticated multi-stroke embellishment process on matte black paper. The complex label design incorporates four distinct production strokes, featuring precise, delicate lining and deep embossing textures.

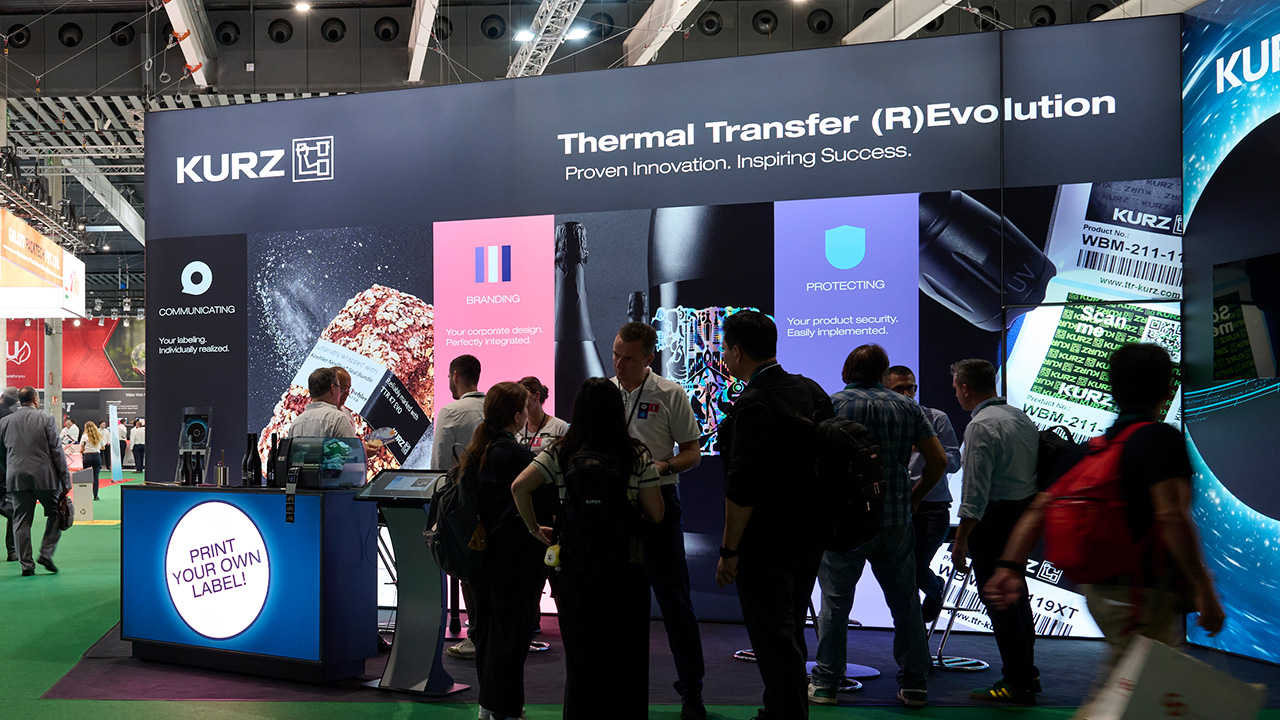

The company utilized Kurz’s DreamComposer software to visualize and optimize the design in 3D before production, allowing for careful selection of structures and color transfers.

ABG announced a partnership with Gietz to integrate the Gietz Rofo 450 or Rofo 570 units into its finishing equipment. The Gietz Rofo 450 Eco module provides a stamping area up to 24in in running length, a stamping force of 100 tons and up to 22,000 strokes per hour.

Kurz showcased live demonstrations of its DM-Uniliner 3D system and presented its expanded range of transfer products, including Silver Line, developed to provide labels with a premium appearance, and Lumafin, which offers a semi-transparent finish. Many Kurz products are now available on reduced thickness carrier materials of 10 or six microns.

The company focused on three distinct digital embellishment technologies at the show. The first, transfer-on-toner technology, demonstrated in partnership with Xeikon, uses heat to reactivate toner as an adhesive layer for metallic transfer. The second, inkjet-on-transfer technology, expands the substrate range from unsupported film to standard prime labels and uncoated materials. The third technology, inkjet-on-substrate 3D technology, enables tactile effects and gloss effects.

Stéphane Royère, head of business area packaging and print at Leonhard Kurz, speaking at the press conference, emphasized the importance of design in embellishment. ‘The start of labels is the design, is the creativity, is the emotion,’ he explained. Kurz presented its DreamComposer software showcased at the show, enabling users to add digital labels on screen and experiment with various embellishments.

Grafotronic unveiled new high-quality Haptic embellishing technology, advancing the company’s finishing capabilities for premium label applications.

Vinsak showcased its Label-Decore finishing machine, generating significant interest from visitors seeking premium label embellishment capabilities. The machine delivers decorative effects, including foiling, embossing and tactile finishes.

‘Finishing is no longer just an added step, but a key driver of differentiation and consumer engagement,’ according to Vinsak.

Prati’s DigiFastOne converting line targets wine and spirits applications, processing materials ranging from 12 to 350 microns in thickness. The system featured a 330mm web width with UV varnishing, semi-rotary hot foil stamping, digital screen printing, semi-rotary die-cutting and rewinding units.

Connected workflows

Integration capabilities emerged as essential for modern finishing equipment, with suppliers emphasizing how their systems connect with workflow software, printing presses and other production equipment to create seamless, automated processes.

Grafotronic’s IQ workflow automation system enables its DCL modular finishing line to perform job changes autonomously, handling all job settings automatically. During production, it constantly monitors and adjusts the register if required, functioning as a virtual operator. IQ sets and keeps the modules it is installed on in perfect register, using a pre-printed mark and cross with no external input required. Grafotronic calls this instant automation.

The system addresses the needs of every label producer who wants or needs faster setup times, less waste during setup, consistent workflows and automatic register quality assurance throughout the production run. IQ is part of Grafotronic Collab Workflow, which unifies and automates the full workflow of label producers, creating a seamless and highly efficient production environment.

The company’s Collab workflow system unifies and automates the full workflow of label producers. From JDF/JMF to REST API, Collab offers comprehensive integration options. The Collab Rest API streamlines machine integration with real-time control through HTTP-based interactions and live WebSocket notifications.

“There’s a crowd around this laser all the time, especially for super short runs where you can stack 100 jobs in one roll”

Grafotronic showcased its Hybrid system in collaboration with Domino Printing Sciences, combining Domino’s N730i Integration Module with Grafotronic’s DCL2 converting and finishing stations. Under the theme We are hybrid, the collaborative showcase demonstrated fully integrated hybrid label production. The complete machine unites digital printing with high-performance finishing in one streamlined process.

Visitors to the Domino Grafotronic Hybrid Arena experienced the complete process live from substrate preparation through to printed and fully finished label rolls, all in a single pass. This collaboration delivers flexibility, speed, efficiency and print quality to label converters, demonstrating how integration eliminates material handling between processes and accelerates throughput.

LemuGroup presented a complete self-adhesive label conversion line in collaboration with Martin Automatic, ETI Converting and Lundberg Tech. The fully automated system begins with Martin Automatic’s MBS non-stop splicers feeding ETI’s Cohesio modular machine, efficiently transforming raw material into finished labels.

A particularly striking feature was the structure designed jointly by the companies: a five-meter paper bridge suspended over the aisle connecting the two stands, allowing attendees to pass underneath.

‘This project represents a strategic collaboration between Martin Automatic, ETI Converting, Lundberg Tech and LemuGroup,’ the companies stated. ‘Each company contributes its expertise, enabling the construction of a highly productive machine.’

Prati’s DigiFast20000 operates both near-line and off-line, integrating with digital printing systems to handle flexible packaging, pouches, sleeves, labels and cartons with processes including registered white, protective UV or water-based varnish and digital embellishment.

Speed and productivity advances

Finishing equipment suppliers demonstrated significant speed improvements, addressing converters’ needs for higher throughput to handle increasing volumes of short-run work.

Grafotronic unveiled its X-1 semi-rotary die-cutting unit, which the company describes as the fastest single-anvil system globally. The machine features a single anvil design for enhanced control from setup to high-speed operation with up to 200m/min. The ultra-high-speed semi-rotary die-cutting unit represents a significant development in finishing technology.

The company also showcased the updated ultra-compact finisher SCF, now running at 100m/min, demonstrating how even entry-level equipment benefits from speed improvements.

Grafotronic presented innovations including the Next Generation Sci-Fi Laser, the fully automatic turret Infinity powered by Serame, a brand-new semi-automatic turret with auto-closing system and the market’s easiest multilayer module, Grafotronic MLL.

The latest version of the AI-driven computer vision virtual operator IQ+ is part of the Grafotronic Collab automation suite.

Brotech’s SpeedMaster semi-rotary flexo and die-cutting system runs at 110m/min in semi-rotary mode and up to 150m/min in full rotary, equipped with the company’s proprietary Digital Pressure Control system.

Bar Graphic Machinery’s 370eDSRT easy load die-cut slitter semi-automatic turret rewinder achieves rotary die-cutting speeds reaching 250m/min, with users reporting productivity improvements of up to 60 percent.

Prati’s Jupiter control table offers inspection speeds up to 400m/min and features semi-rotary die-cutting capability, handling mid-web print runs in a 670mm web width configuration. The system was presented for the first time with semi-rotary die-cutting, offering maximum safety, 100 percent quality and flexibility.

Nicely Machinery introduced the EG-8002 series slitter rewinder, offering expanded capabilities for high-volume production, with support for rewind diameters of up to 1,200 millimeters and speeds of up to 800m/min.

GM launched a new, upgraded DC350Flex fast finishing system. The Flex model range is a modular finisher engineered for high-speed digital label production, offering die-cutting up to 120m/min with semi-rotary and single anvil capabilities.

RFID converting advances

RFID label converting technology demonstrated significant advances, with suppliers introducing systems designed to meet the rapidly expanding market for smart labels.

BW Papersystems launched the SpeedLiner X, a radio frequency identification converting machine that delivers up to 25 percent higher annual output compared to conventional systems. The machine supports up to four tracks for simultaneous production, enabling converters to dramatically increase output.

‘With the RFID market expanding at over 30 percent annually, converters worldwide are under pressure to increase throughput, improve reliability and scale efficiently,’ explains Felix Waniek, strategic product manager at BW Papersystems. ‘The SpeedLiner X is a game changer. With up to four tracks, it delivers unmatched throughput, allowing you to produce more, faster.’

The machine features smart automation, including auto get-ready, auto sync and auto register functions, combined with an intuitive human-machine interface and advanced assistance systems that enable operators to set up and control the machine with minimal training.

The modular design allows configuration to meet current and future production needs, with the ability to add multitrack capabilities or additional attachments as requirements change.

GM unveiled the LR250+ RFID inspection system, providing 100 percent in-line RFID tag testing, high-speed RAIN/NFC encoding and automatic marking of any faulty tags. Fully integrated into GM’s modular rewinder, the LR250+ enables converters to achieve seamless inspection, encoding and rewinding in one continuous workflow.

Tamarack Products presented its RFID inlay insertion equipment, offering versatile configurations as a standalone system or integrated with a flexo press. Designed to handle production needs from low to very high volumes, the equipment inserts all types of inlays—both wet and dry—at high speeds with accuracy.

Scalability is a key feature of the Tamarack system, allowing label converters to expand as their volumes increase by adding lanes and other specialty modules. The equipment's modular design enhances flexibility, enabling optimized production for products that may require top or bottom lamination, hot melt applications, multiple die-cut stations and variable data printing.

The equipment includes an inspection module that ensures quality and can encode post-insertion if required.

LemuGroup presented the LI 220 RFID in combination with the Voyantic Tagsurance 3 module, offering real-time coding and quality control in a compact, modular system for high-quality smart labels.

DeltaModTech showcased its RFID label converting products with a live demonstration on its Delta Crusader platform running at 120m/min.

Inspection technology integration

Inspection systems have continued to evolve from standalone quality control devices to integrated data sources that inform production decisions and optimize workflow.

Bar Graphic Machinery’s 450 Label-I 200 percent Automatic Inspection Slitter Rewinder inspects both sides of the web simultaneously while slitting and rewinding. Optional features include 2D and 3D inspection, PDF management, reporting and comparison, plus UV and RFID inspection capabilities.

Prati’s Saturn control table in 450mm web width featured camera inspection for fast-moving consumer goods and personal care labels, while the Saturn Bidi bidirectional inspection table serves pharmaceutical, cosmetic and security sectors with 100 percent quality control, with inkjet heads for variable data overprinting.

The company also unveiled Saturn Next, an intelligent control system featuring automated quality control with defect rejection and splicing capabilities. Key highlights include the Fastcut self-sharpening cutting system with automatic blade positioning and smart features such as Make Ready for quick job changes.

The company invested significantly in its exhibition presence, with a stand of almost 800sqm designed to provide visibility to eight lines with nine machines on display. In total, Prati showcased 12 machines, with three Saturn units also featured at the booths of partners AVT, DecoSystem and BST Eltromat Italia.

LabelTech showcased its Ortles slitter rewinder featuring 100 percent inspection, along with the Sciliar horizontal bidirectional rewinder with variable data print and verification.

Rotocon presented the Ecoline RSI 540, a fully servo-driven finishing machine for label slitting, inspection and rewinding, combining user-friendly operation with low maintenance requirements and production speeds of up to 300m/min.

Modular and flexible configurations

The trend toward modular equipment enables converters to configure systems precisely for their needs while maintaining upgrade paths for future requirements.

Flexor presented modular machines for label finishing, including slitting, die-cutting, inspection and digital processing.

Each system is built to order and tailored to customer needs, combining flexibility, ease of use and high productivity.

Brotech’s SDF PLUS 370 smart modular digital label finishing platform offers flexibility with a patented intermittent flexo unit featuring quick changeover to rotary mode. Available in 330, 370, 420 and 520 sizes, it supports bidirectional workflow.

Rotocon’s Chrome RDF 340 features a modular architecture that supports customized configurations as converters’ needs evolve, including options for hot and cold foil, embossing, multilayer labels, in-mold labeling and screen printing.

‘Our goal has always been to deliver services that combine innovation, reliability and cost-effectiveness,’ commented Rotocon’s board of directors. ‘The positive response and strong sales reaffirms that our technology is helping printers and converters enhance performance, efficiency and value for their customers.’

Relationships and service

Several suppliers emphasized that equipment sales represent only the beginning of customer relationships, with ongoing support and service determining long-term success. Pedro Teixeira of Lemorau highlighted how the company differentiates through customer relationships. ‘The support is very important for us, because the first machine is the sales team that makes it sell, but second, third, and so on will be the support. We have many customers worldwide who believe in us, and we are really happy with what we are achieving.’

Prati dedicated an entire area to after-sales services to showcase the benefits of its new Fastlane platform, providing fast technical support accessible around the clock from the Prati website for submitting requests.

The system enables customers to open tickets and track various resolution steps in real-time, with remote connection capabilities for telediagnosis and troubleshooting.

Market outlook

The finishing and embellishment sector’s evolution reflects fundamental shifts in the label industry. As labor availability tightens and run lengths shorten, automation becomes essential rather than optional.

Digital technologies eliminate the need for specialist skills while expanding creative possibilities. Laser systems provide the flexibility required for high-mix production environments.

The integration of finishing equipment with broader workflow systems signals a maturing industry where isolated machines give way to connected production environments.

Premium embellishment capabilities have evolved from specialized offerings to mainstream requirements as brand owners seek differentiation in competitive markets.

Equipment suppliers demonstrated remarkable innovation across the technology spectrum, from entry-level systems enabling smaller converters to access finishing capabilities to sophisticated multi-unit lines that combine numerous processes.

The emphasis on sustainability, evident in technologies like EcoLeaf on-demand metallization and laser systems that eliminate die waste, indicates how environmental considerations increasingly influence equipment design and material selection.

“Finishing is no longer just an added step, but a key driver of differentiation and consumer engagement”

For converters, the message from Labelexpo is clear: finishing and embellishment technologies now offer the automation, flexibility and creative capabilities necessary to thrive in an industry defined by shorter runs, labor constraints and escalating quality expectations.

The convergence of digital embellishment, laser converting and automated workflows creates new possibilities for differentiation and operational efficiency.

The significant number of machine sales and partnership agreements concluded during the exhibition demonstrates strong market confidence in finishing technology investments.

Suppliers reported order levels exceeding expectations, with particular strength in laser systems, digital embellishment equipment and automated turret rewinders.

As the industry advances, finishing and embellishment capabilities will continue to differentiate successful converters from those struggling to meet market demands. The technology showcased at Labelexpo Europe 2025 provides the foundation for this differentiation, combining productivity, quality and creative possibilities in ways previously unattainable.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.