Extended content labels can maximize communication

In a world where shelf appeal and information dissemination are paramount, ECLs are becoming powerful tools for communication. Find out how?

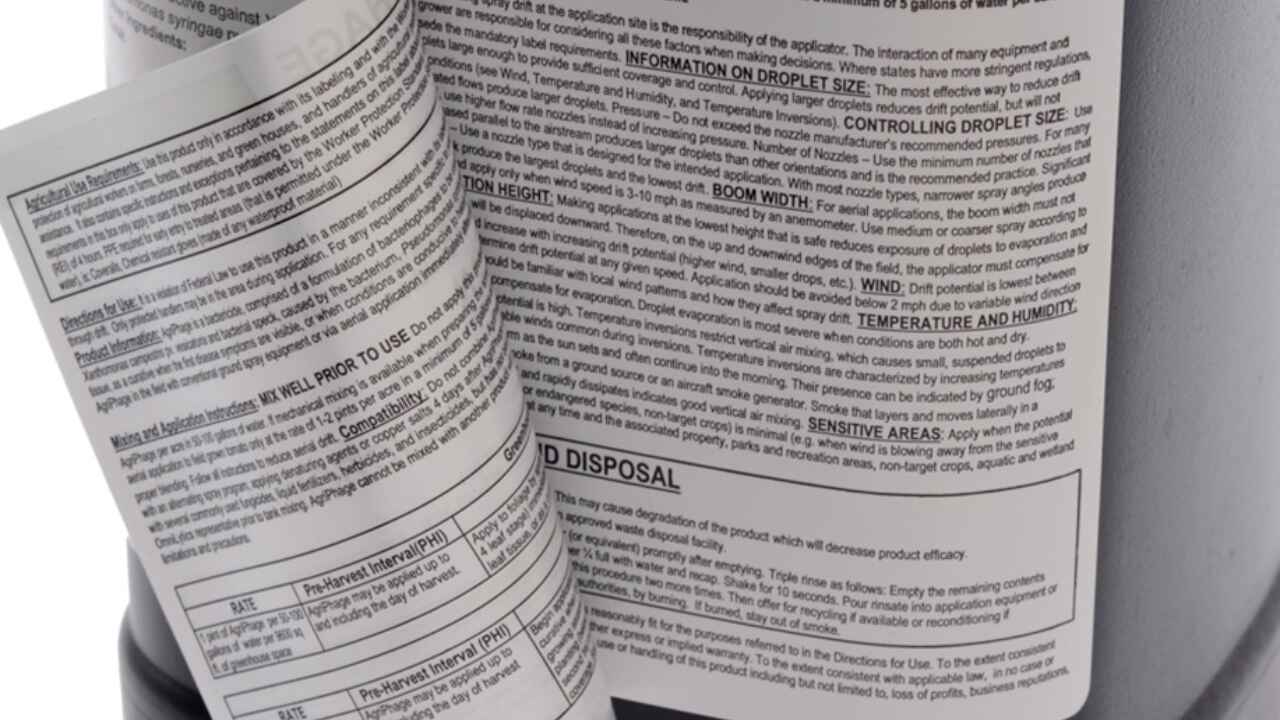

Booklet label developed by Schreiner MediPharm for Sanofi’s needle protection system.

It all began with a pressing challenge: how to fit more information on a product label without compromising branding or shelf appeal?

In the 1970s, as regulatory frameworks in pharmaceuticals and agrochemicals became more complex and international markets expanded, manufacturers needed to provide multilingual instructions, dosage details, safety warnings and compliance information, often within limited packaging space. The answer? Booklet labels.

Pioneered in Europe and quickly adopted by global pharmaceutical and chemical companies, the first booklet labels were small printed leaflets attached to containers. Early innovators, such as CCL Industries and Denny Bros in the UK, played a key role in this development. The latter patented the Fix-a-Form label, a multi-page booklet label that combined adhesive labeling with printed literature in a single, space-efficient format. These labels allowed manufacturers to wrap crucial information around bottles, cans and vials, opening like a book, yet securely attached to the product throughout its lifecycle.

Over the decades, this concept evolved, driven by improvements in materials, adhesives and printing technology. What started as a necessity in the pharmaceutical sector soon expanded to other industries, giving rise to the broader category of extended content labels (ECL).

Market size does matter

ECLs are any type of label that creates additional space, often through the use of extra panels or pages. Traditionally, labels are printed on one side of a piece of material, but ECLs typically utilize additional sides and panels to hold more information.

This format can take many shapes: intricate booklet labels that unfold like miniature guides, eye-catching instant redeemable coupons (IRCs), clever multi-layer ECLs packing information into tight spaces, and labels embedded with digital triggers. They’ve become indispensable tools in the modern marketing and packaging toolkit, shaping how products are presented, understood, consumed and purchased.

‘The ECL market has been rapidly evolving as consumer demands for detailed, transparent and easily accessible information on packaging increase,’ notes Richard Miedema, global sales director of MPS Systems.

These aren’t just a niche corner of the industry but a significant force. The market size of extended content labels was valued at 15.59 billion USD in 2023 and is projected to reach 45.6 billion USD by 2031, according to Verified Market Research. The market is expected to grow at a compound annual growth rate (CAGR) of 16.3 percent from 2024 to 2031, according to the market research agency.

Sharing her experience on the rising demand for ECLs, Cristina Arcos, general manager at US-based Blue Line Labels, observes: ‘We have seen an increase in orders for ECLs from customers expanding internationally. The need to include multiple languages on packaging has led brands to adopt ECLs as a solution for adding additional languages and regulatory information without cluttering the label.’

“The need to include multiple languages on packaging has led brands to adopt ECLs as a solution for adding additional languages and regulatory information without cluttering the label.”

The label industry is experiencing robust growth in ECLs across a broad spectrum of sectors, including automotive, healthcare, telecommunications, electronics and industrial manufacturing. This wide-ranging applicability is encouraging manufacturers to tailor offerings to sector-specific needs, fueling innovation and product diversification.

Manon Van Der Linden, sales manager at Belgium-based Asteria Labels, says: ‘We expect a rise in the adoption of multilayer labels and booklet labels to meet the rising demand for enhanced customer information such as multilingual usage guidelines, culinary instructions, safety precautions, exclusive discounts and exciting competitions. The booklet label offers a compact solution for presenting extensive information within a confined space.’

Asteria Labels has over 35 plants across Europe, providing a range of labels, flexible packaging and folding cartons for the pharmaceutical, food and beverage, animal care, personal care and FMCG industries and beyond.

Key industries targeted

The applications of ECLs span numerous industries, but pharmaceutical and nutraceutical markets are obvious places for extended content labels to thrive.

“The marketing department is rightfully selfish. They are fighting for consumer eyes on the shelves or retail stores.”

According to Future Markets Insights, the pharmaceuticals segment is expected to record the fastest CAGR of 6.8 percent from 2025 to 2035 in the ECL market. This growth is characterized by the stringent requirements imposed by regulatory bodies such as the US Food and Drug Administration (FDA), the European Medicines Agency (EMA), and the World Health Organization (WHO).

This emphasis on regulatory adherence has propelled the demand for innovative specialty label techniques that effectively convey vital drug information to healthcare professionals and patients. Leading the innovation arena in this segment is Schreiner MediPharm.

Part of the Germany-based Schreiner Group develops and produces innovative specialty labels for the healthcare industry. Its 32-page booklet label for the French multinational pharmaceutical and healthcare company, Sanofi, with medical information in 22 languages, is a classic case in point.

‘When Sanofi conducted an international phase III clinical trial, it sought a label for its needle protection system that provided complete information in several languages. The label also had to firmly adhere to the plastic needle protection system without impairing its functionality,’ shares Dr Jens Vor der Brüggen, director technology and innovation management at Schreiner Group.

He continues further: ‘Among the most complicated ECL applications we encounter is when a client needs to place a large number of pages around a small diameter vial or syringe. This is akin to wrapping a small book around a curved surface. Try it, it’s not easy. Even if the paper used is exceedingly flexible, when the booklet is wrapped, it’s a challenge to ensure reliable adhesion of the label with the integrated booklet to the container. It requires extensive know-how regarding materials and printing technologies to yield a perfect ECL fit.’

The company developed a compact booklet label tightly wrapped around the needle protection system. The label adheres to the plastic substrate of the needle protection system. Due to the flexible construction of the thin booklet paper and film layers, it can be easily wrapped around the quadrangular device. A starter tab allows for easy opening and re-closing of the label.

‘The booklet label is partially affixed to the device, allowing the pre-filled syringe and its contents to be readily visible after opening. The booklet features perforations, allowing for its removal before an injection; only a small part of the label remains on the device. The label material is suitable for custom overprinting using thermal transfer printers to support the processes during the clinical trial,’ informs Vor der Brüggen.

Serving looks

Labels are instrumental in fitting both regulatory requirements and branding information all on one label. However, adding all the content can clutter the label, affecting the overall design. ECLs provide a more elegant alternative, allowing one to design around legally required statements without compromising visual aesthetics.

Talking about how extended content labels have given a fresh look to brands trying to balance between content and design, Jeff Bertrand, founder of JH Bertrand, says: ‘Our client, SK Floor Cleaner, wanted to revamp the product label where the regulatory copy overshadowed the brand identification and benefit statements. In the ‘before’ product, SK’s label doesn’t stand out. There is too much copy with no white space. It ‘looks dangerous’ to use, given all the legal copy screaming for attention. As a consumer, I might walk right past this product because it doesn’t look friendly.

‘However, the ‘after’ product shows great improvement. The non-selling, intimidating regulatory copy is inside the booklet label. The label has a more prominent brand name and logo. More copy space has given the company designers a chance to add a beautiful color pattern. Additionally, the benefit statements are in larger fonts, helping to explain why the customer should purchase the product. The use of a booklet label has enabled SK to change its image, allowing it to stand out above the competition.’

ECLs also play a vital role in impacting how consumers perceive a product. Regardless of industry, brand identity is essential in labeling to ensure authenticity.

‘The marketing department is rightfully selfish,’ says Tom Spina, president and CEO of Luminer, a label manufacturer from Lakewood, New Jersey. ‘After all, the marketing and sales departments are fighting for consumer eyes on the shelves or retail stores. By using an extended content label, both the marketing department and the regulatory department can be satisfied, giving both the room they need on the package.’

Accelerating retail action

Coupons have been a powerful tool to drive sales, support marketing initiatives, and boost visibility since 1887, when Coca-Cola co-owner Asa Candler conceived the brilliant idea to distribute handwritten tickets to consumers that could be exchanged for a complimentary glass of Coke. That marketing strategy resulted in Coca-Cola being served in every US state by 1895.

Today, these coupons have taken the shape of instant redeemable coupons (IRCs), serving an effective role in the marketplace.

Throwing more light on the role of IRCs in influencing consumer behavior, Kim Hensley, product manager at US-based Mactac Roll Label, says: ‘If a consumer is looking at several products side-by-side, the one with the promotional offer will move off the store shelves faster than the products without. If it is a coupon label, the consumer feels good about their purchase because they received an additional saving. It sets you apart from the competition.’

IRCs will always be a leading force in product marketing. Due to the retail space being a competitive marketplace, IRCs are a crucial final piece of a marketing strategy to capture the consumer’s attention and sway purchasing decisions.

Talking about how critical IRCs can be, Mike Apperson, CEO and president of US-based Resource Label Group, recalls: ‘We had a personal care brand that wanted to run an on-package promotion using an IRC. However, there was a challenge. The product came in a small tube with limited design real estate. Our client requested that we engineer and print an IRC label that would maintain the existing space visibility and seamlessly integrate with the product packaging.

‘Due to the special nature of the challenge, we printed and designed a custom label that used a tombstone-shaped tube flag. Instead of taking the well-worn approach and placing the IRC on the tube’s backing, we increased the product’s visual height by adding the IRC to the top. Normally, an underused area became a billboard that served a functional purpose and seamlessly accented the product design.’

Navigating the challenges

Despite the excitement for extended content labels, the path to growth isn’t without its bumps. Stakeholders face several ongoing challenges.

“If a consumer is looking at several products side-by-side, the one with the promotional offer will move off the store shelves faster than the products without.”

The rise in raw material prices seriously discourages market growth in ECLs. Since producers depend on several materials, including paper, synthetic paper and plastics, to produce labels, any increase in the cost of these raw materials affects total production costs. This can make end products more expensive, making them less competitive.

Furthermore, higher expenses can compel producers to downsize the quality or functionality of labels in order to preserve profit margins, thereby lowering consumer satisfaction and confidence. The higher raw material prices thus present a difficult situation for producers to innovate and grow, constraining the market’s growth for specialty labels.

Cost is another factor that hinders the growth of specialty labels. Due to the complexity of their construction, the use of advanced materials, and potentially slower production speeds, specialty labels often cost more than standard ones. ‘Design can impact costs. Some brands just want coupons that help products move and deliver messages like “Save 50 cents”. Others want a premium piece that conveys the brand’s value,’ shares Aaron Kilgore, regional vice president for Resource Label Group.

The rapid pace of technological change also puts financial strain on companies that must continuously update their equipment and processes. Adding sustainability goals to the mix further complicates this equation, as eco-friendly materials or processes may sometimes carry a cost premium, although this gap is narrowing. Finding the sweet spot that delivers performance, sustainability and value is key.

The specialty labels market faces challenges related to consumer awareness and perception. Despite the advantages of ECLs, many consumers may not fully understand the benefits or functionalities of extended labels. This lack of awareness can limit the market’s growth, as consumers may not seek products with specialty labels. Additionally, ensuring consistency in labeling standards across different regions remains a challenge, as variations in regulatory requirements can complicate the production and distribution of ECLs.

In recent years, supply chain vulnerabilities have also been highlighted as a threat to those in the labels industry. Shortages or delays in specialized films, papers or adhesives can halt production.

However, where challenges exist, there are also tremendous opportunities.

Significant growth opportunities exist in emerging markets, where the adoption of advanced packaging continues to accelerate. Specific industry segments, like nutraceutical, cannabis or craft beverage markets, present fertile ground for innovative labeling techniques.

Additionally, technological advancements such as faster digital presses, smarter sensors, more sustainable materials and new interactive possibilities open doors for creative design and new applications that were previously impossible or impractical.

The next chapter

As brands look to do more with less — less packaging, less waste and less confusion — extended content labels provide the extra space, storytelling capacity and intelligence needed to meet today’s packaging challenges and tomorrow’s consumer expectations.

The message is clear for brand owners, converters, suppliers and technologists alike: The label matters more than ever. Investing in future-ready labeling practices isn’t just about keeping up; it’s about unlocking new ways to connect, inform, persuade and, ultimately, succeed in tomorrow’s complex and competitive marketplace.

Know your labels

Booklet labels, also known as multi-page, multi-ply, multi-layer, or onserted labels, are among the most commonly used labels to pack extensive information into a small label area. These labels print separately from the product label and can be added later to optimize your branding efforts.

Instant redeemable coupons are among the best-known marketing strategies. Usually constructed with a clear, adhesive-backed liner that serves as the base label, a coupon is printed on a separate piece of paper and is attached to the liner, creating a ‘peel-away’ or ‘peel here’ style label.

Peel-and-reseal labels are designed to enable the end-user to open and seal the label multiple times. They can take three to five panels of information within the confines of the regular prime label size.

Peel-back labels are similar to peel-and-reseal labels. These labels feature either a hinged top layer that remains connected when peeled or a peel-away top layer that can be applied to another surface.

Piggyback labels are a type of label construction where one label is placed on top of another in a single-use manner. The top label is removed and either used or discarded, and the bottom layer is either clear or contains information.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.