Technotrans and Windmöller & Hölscher deepen partnership

Companies sign an exclusive deal for the Turboclean Advanced E ink supply system in flexographic printing.

Technotrans and Windmöller & Hölscher (W&H) have strengthened their cooperation by signing an exclusive framework agreement for the supply of the jointly developed Turboclean Advanced E ink supply system, designed to meet increasing demands for efficiency and sustainability in high-performance flexographic printing.

The system will be used exclusively in W&H flexographic printing presses. The agreement secures Technotrans an order volume in the low double-digit million euro range, underscoring its system expertise in fluid management for print applications.

'By continuing this close cooperation, we are securing significant revenue potential and consolidating our strong position in the print focus market,' said Michael Finger, CEO of Technotrans SE. 'The approach we have developed together with W&H provides clear competitive advantages in terms of efficiency, sustainability and operating costs.'

The development of the complete ink supply system for flexographic printing presses, used to print films for the packaging industry, was carried out in close, multi-year collaboration. To optimally support the development and intensive testing phase, Technotrans temporarily deployed a resident engineer at W&H.

'Our goal was to create a system that consistently meets our high standards for performance, resource efficiency and user-friendliness in flexographic printing,' said Dr Björn Feldhaus, head of printing press development at W&H. 'With Technotrans, we have found a development partner who implemented our concept excellently with technological expertise. We are delighted to further strengthen this successful partnership with the new framework agreement.'

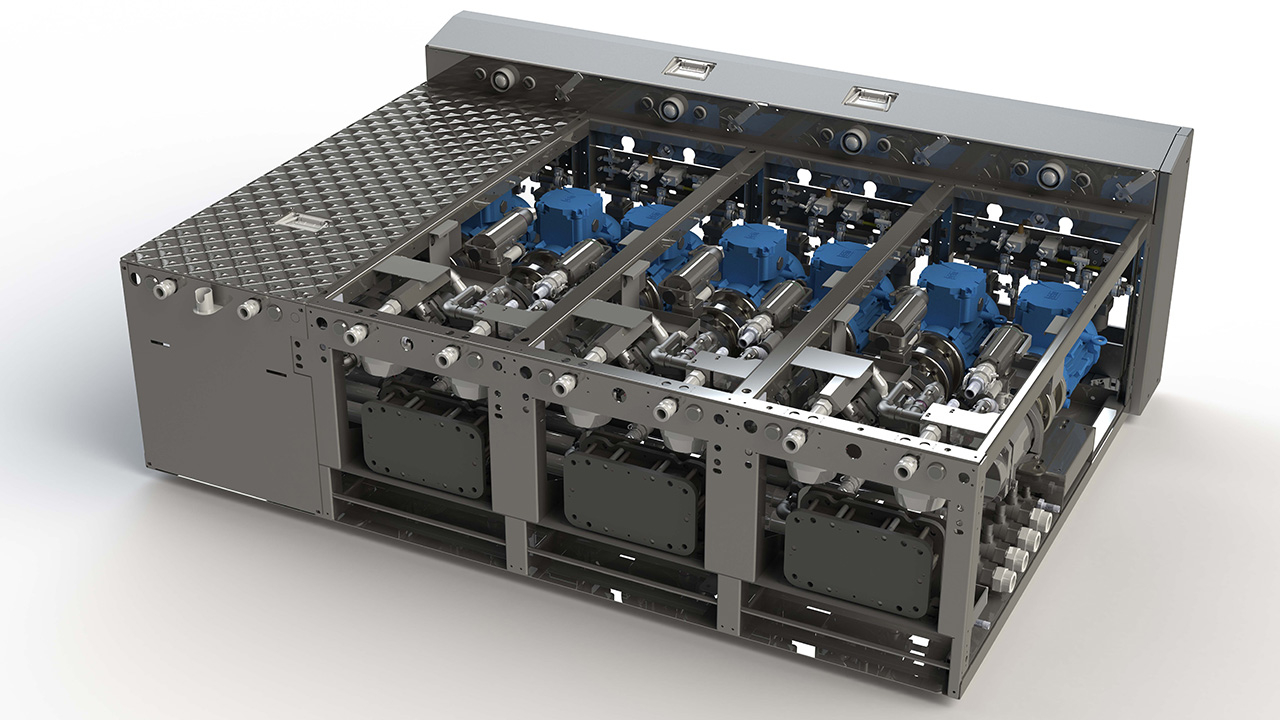

The core of the Turboclean Advanced E system are electrically operated piston pumps, rather than the commonly used pneumatically driven diaphragm pumps. The resulting advantages are significant compared to conventional systems. They enable energy savings of up to 80 percent. In addition, the system minimizes ink loss during the frequent color changes typical in flexographic printing. The pump technology allows residual ink to be recovered from the lines and returned to the circuit.

Faster color changes in just five minutes and significantly extended maintenance intervals, thanks to the use of low-wear pump components, are further benefits. The piston pumps feature statically loaded seals, making them particularly durable against the abrasive components in printing inks – a decisive advantage compared to pumps with dynamically loaded seals.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.