Ambitious Arclad seeks foreign growth

With a second factory and two new product ranges, Colombian labelstock manufacturer Arclad has ambitious plans to target the US market. James Quirk reports

Colombian labelstock manufacturer Arclad is used to constant growth. The company strives to double its sales every four years – and has achieved this in every such time frame since 1984. Its headquarters in Rionegro has undergone 13 separate expansions; beginning with 768 sqm in 1980, the site now stands at nearly 12,000 sqm.

One of Latin America’s leading labelstock suppliers, the company opened a new plant in Cartagena, Colombia, two years ago. This site, representing an investment of USD 23 million and dedicated entirely to export, brings Arclad’s production capacity to 244 million sqm of materials a year.

Now, with two new high quality ranges added to its portfolio and making its debut at Labelexpo Americas in Chicago in September, the company has ambitious plans to expand its presence outside its traditional markets. With the Cartagena plant strategically located in the Colombia’s closest port to the United States, and aided by the free trade agreement signed by the two countries in May this year, Arclad has set its sights on the giant market to the north.

Regional presence

Arclad – exporting 70 percent of production – already has a large regional presence in Latin America, with its two manufacturing sites in Colombia complemented by local slitting and distribution centers in Costa Rica – which serves the rest of Central America – Ecuador, Peru, Venezuela, and three in Mexico: in Mexico City, Guadalajara and Monterrey. All these sites are equipped with slitter rewinders from UK-based Ashe Converting. Lesser quantities of material are also sent to Argentina, Brazil, Chile and Uruguay.

Arclad produces self-adhesive paper and film labelstock for a wide variety of end user applications, including food, personal and household care, pharmaceutical, cosmetics, industrial, textile and school supplies.

Its product line includes BOPP and PE plastic films; hot melt, matt, fluorescent and thermal papers; and metalized papers and films. Its adhesives range includes FDA and ISEGA-certified products, and adhesives for frozen food, pharmaceutical and security applications.

Ultra-destructible resins were added to this latter range in 2010, aimed at anti-counterfeiting applications.

These product lines have been added to this year with the launch of wine label and security films ranges. Wine production is growing – albeit from a low base – in countries such as Brazil and Mexico; while Argentina and Chile remain the region’s biggest markets. The new wine label material range represents Arclad’s first move into the sector, and is said by marketing manager Laura Durango to be a key focus.

The security film range, meanwhile, is aimed at brand protection applications and allows the end user to customize the product according to its needs. Not only void text is left remaining, but also metalized material which can contain a personalized message or company logo.

Production

Arclad was founded in Rionegro, near the city of Medellin in the Antioquia district, in 1980 by Vicente Ferrer. It took the first two letters of its name from Pennsylvania, USA-based Adhesives Research, from whom Ferrer sought investment and support. With intelligent foresight, he purchased the land where the company is located to this day because its size would allow for significant expansion of operations. The original factory of 768 sqm has since given way, via 13 different expansions, to a 12,000 sqm plant which houses some 230 staff and has a production capacity of 12 million sqm a month.

Arclad became the Colombian market’s second local labelstock manufacturer, after Carleib. It is no longer in business, but Arclad was joined in the local market by Avery Dennison’s manufacturing site in Medellin in 1998.

The Rionegro site houses a silicon coating machine from Germany-based Kroenert for silicon application on paper and transparent polyester film. Installed in 2006, Arclad says it remains the only such machine in Colombia. An inline laminator with emulsion technology for adhesive application was installed in 2001 and has been repeatedly upgraded. A hot melt adhesive laminator from Nordson was installed in 2005, and the company was the first producer of hot melt label materials in the country.

According to Juan David Duque, product director, emulsion is used for 80 percent of production, with hot melt making up 20 percent.

The Cartagena operation – at 10,000 sqm with 120 staff and a production capacity of eight million sqm a month – hosts a silicon coater for application of solventless silicon with thermal curing, also from Kroenert.

The site was built from scratch and adorned with new equipment, with the exception of one siliconizer transferred from Rionegro. It also houses a laminator which has been configured to apply adhesive via either emulsion or hot melt technology, thanks to a combination of equipment from Kroenert and Nordson.

Finishing in both plants takes place on a fleet of Titan and Kampf slitter rewinders. Rionegro houses five roll to roll and two roll to sheet machines; Cartegena hosts four roll to roll rewinders and one roll to sheet.

Among other equipment at the Rionegro site is a flexo press, used for printing labels for Arclad’s own products and for testing the performance of new materials. A smaller coater is also dedicated to testing and development.

The company attaches great importance to research and development; its laboratory buzzes with nearly 30 employees and is equipped with a variety of testing systems from ChemInstruments.

According to marketing manager Laura Durango, Arclad has managed to absorb some of the rises in raw material prices by manufacturing substitute products, reducing the weight of rolls, and developing thinner materials. ‘It’s a price-driven market,’ she acknowledges, ‘and we’ve been able to keep prices for the local market pretty constant. Export markets are different, though, because they are affected by dollar fluctuation. We try to make the price not the only reason to buy our materials, so we focus a great deal on after sales service.’

An example of such a service is how the company assists its customers in improving their production efficiency. Arclad works with a consultant who is sent to the converter to review its operations and help to make improvements.

Environmental focus

With environmental sustainability of ever-increasing importance in the label industry, last year Arclad began an impressive initiative which sees the company reuse its liner waste. A dedicated division, RexAr, recycles many tons of material waste every month in a pulp molding process to make cardboard trays for eggs and drinks.

The project will have paid for itself within a few years: it has halved waste disposal costs as well as reducing the company’s environmental impact.

‘Although not much money is made through the initiative, it saves the cost of disposing of the waste and brings significant environmental benefits,’ says manufacturing manager Alejandro Gonzalez.

The local community has also benefitted – previously, these types of products were brought in from other parts of the country, such as Bogota and Bucaramanga, with prices higher due to transport costs.

The waste material has other possible applications – such as plant pots and protection for the corners of household appliances like fridges – but the immediate focus is to reuse this waste within Arclad’s own material ranges. The company expects this to begin later in the year.

The local government of Antioquia, the district where Arclad’s Rionegro plant is located, is demanding when it comes to environmental issues. A further initiative, in partnership with a local government environmental project called Cornare, sees waste materials treated and deployed in children’s playgrounds, or parques ecológicos.

Arclad is certified to ISO:14000 and uses no solvents in production. In corporate responsibility initiatives, it offers loans to employees that have worked at the company for more than five years, and also gives scholarships to local students to help them pay for higher education.

With the added production capacity of its plant in Cartagena, new high quality materials and impressive environmental credentials, Arclad seems set to continue the growth to which it has become accustomed.

Colombia in context

Arclad estimates annual Colombian label market consumption to be around 88 million sqm a year. With a population of some 46 million, this puts the country’s annual per capita label consumption at 1.9 sqm, a figure not far from the region’s more developed markets of Brazil and Argentina.

Colombia has been one of the region’s recent success stories. Under president Juan Manuel Santos and his predecessor Alvaro Uribe, the country’s security and economic growth have significantly improved. Foreign direct investment has risen almost tenfold since 2003, to USD 13.2 billion in 2011. The economy grew at six percent last year and is closing in on Argentina as South America’s second largest.

Colombia hosted the Summit of the Americas in the Caribbean port city of Cartagena on April 14 and 15, welcoming US president Barack Obama and 31 other western-hemisphere heads of state. During the event, president Juan Manuel Santos told Time magazine that Colombia was ‘not just a recovered nation, but the new economic and diplomatic player on the Latin American calle, or street’.

A free trade agreement between Colombia and the United States came into force on May 15 this year, in a further boon to a country that has seen a dramatic reversal in fortune in recent years.

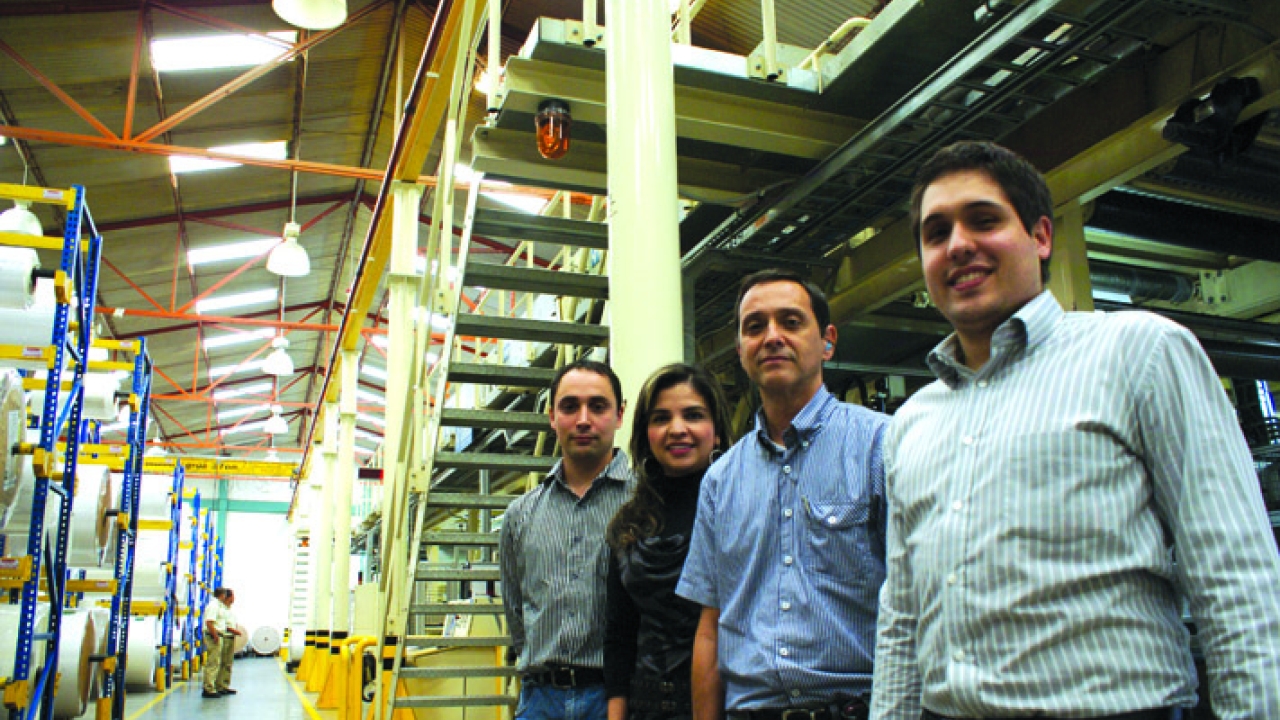

Pictured: (L-R) Federico Restrepo, technical manager; Laura Durango, marketing manager; Alejandro Gonzalez, manufacturing manager; and Juan David Duque, product director

This article was published in L&L issue 4, 2012

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.