Automated shrink sleeve production to debut at Labelexpo Americas 2018

In a world first, automated shrink sleeve production is to feature as part of the Automation Arena at Labelexpo Americas 2018.

Automation Arena debuted at Labelexpo Europe 2017, but this year will mark its first appearance at a trade show in the Americas. More importantly, automated shrink sleeve production will be shown for the first time at a trade show anywhere in the world.

This will see slit rolls of flexo-printed shrink sleeves transferred to an Accraply ASFC fully continuous forming and seaming machine. There, an identification barcode is scanned and the instruction file from the code read to automatically set-up the forming and seaming operation. Secondly, the lay-flat shrink sleeves are transferred to an Accraply DM12 Shrink Sleeve Inspector, a compact vertical seaming inspection machine used for lay-flat quality checking.

This element of the Automation Arena will come after labels are printed using digital and flexo technology.

Alongside Accraply, Avery Dennison, AVT, Cerm, Esko, Grafotronic, Klockner Pentaplast, Kocher + Beck, Matho, MPS, Xeikon/Flint Group, WLE and Zeller+Gmelin are taking part in the Automation Arena at Labelexpo Americas 2018.

Between them they will be digitally printing several different self-adhesive label designs and flexo printing shrink sleeves ‒ all on two fully automated live press lines.

The Automation Arena will cover job creation, right through to pre-press, printing, inspection, finishing, waste removal, warehousing and customer invoicing. This will all be centrally managed by a Cerm management information system (MIS), and integrated with an Esko software platform, supporting end-to-end label and shrink sleeve workflow.

Located in Hall F of the Donald E. Stephens Convention Center in Chicago, the Automation Arena will be showcasing three 30-minute demonstrations on the first two days of the show at 11am, 1pm and 3pm, and a further two on the last day at 11am and 1pm. Each session will be filmed live and relayed via large screens to show visitors every detailed aspect of the job.

The initial job creation, artwork uploading, MIS order processing and workflow automation for both presses will take place in Cerm’s system before label personalization, pre-flighting, quality checks, color management, the creation of rules for inspection, proofing and customer approval are progressed using Esko’s software platform and Automation Engine. This will be followed by Cerm scheduling and substrate checking, tool ordering and the sending of JDF files, ready for digital label printing to a Xeikon CX3 press, integrated with a Xeikon laser die-cutting unit, turret rewinder and Matho waste removal. This digital jobs are being printed on Avery Dennison 79100 Fasson 2 Mil white top coated self-adhesive facestock and using a Flint Group Digicoat gloss varnish.

When the Xeikon press starts its run for label printing, the audience will be able to see the different identification barcodes in operation, AVT defect detection, laser die-cutting set-up and rewinder automation.

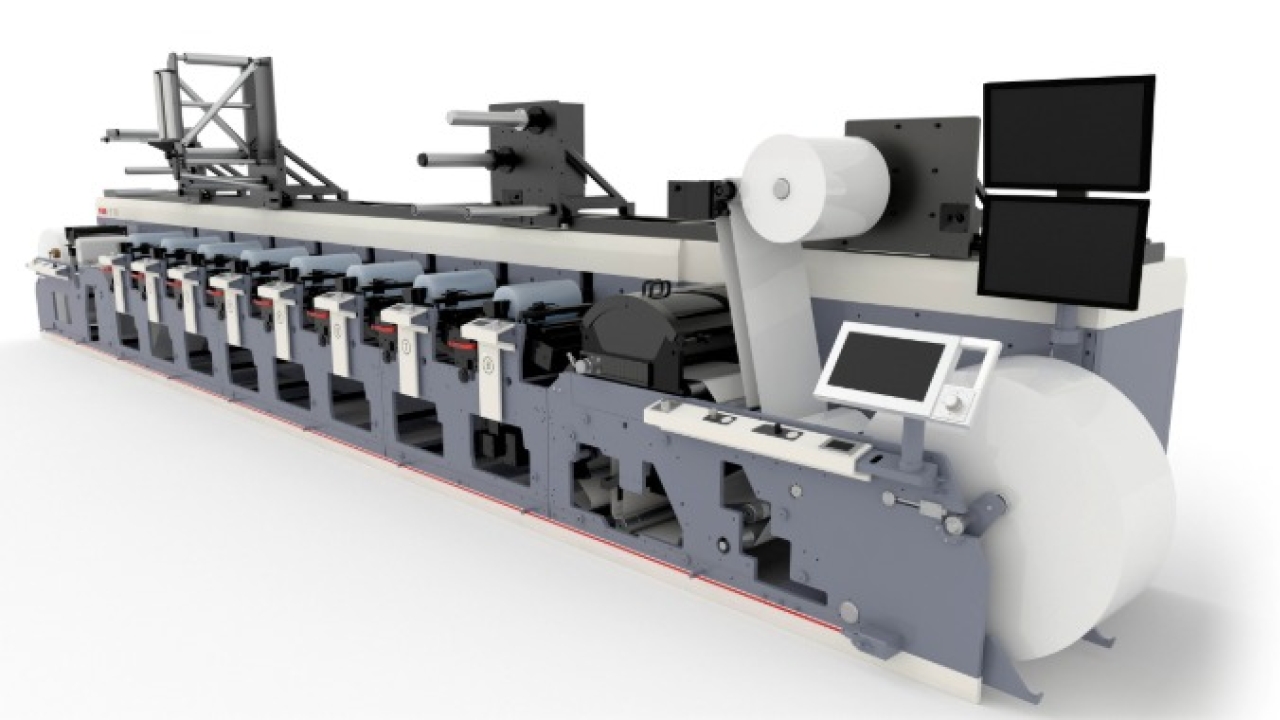

The conventional flexo press shrink sleeve print runs will be produced on an MPS EF 430, 8-color flexo press – with no gear cylinder connection, intelligent pressure setting and zero waste roll change – which in turn will be fitted with a Kocher + Beck UR Precision 440 U non-stop butt splicer and AVT’s Helios inspection technology. The MPS press will be printing on Klockner Pentaplast PETG 50 micron sleeve film using Zeller+Gmelin’s 32 Series Nuvaflex range of UV flexo inks developed specifically for sleeve production. The MPS EF 430 operator reads the MIS-generated job ticket on screen, enabling them to check that plates, tools, inks and substrate had been delivered, and changing the unwind roll butt splicer. Each roll loaded is scanned and becomes fully traceable throughout the whole process, interacting with the Cerm system in order to provide real-time production values. A Cerm inspection command is also sent to the AVT’s automatic press inspection function, which monitors printing defects.

Printed rolls coming off the flexo press will be identified with an ID barcode which, when scanned, enables an electronic instruction file to automatically set-up shear slitting on a Grafotronic high-speed inspection slitter rewinder. An AVT camera will then automatically stop the machine whenever a defective label is detected in the printed reel so that any repairs can take place. The final, ‘clean’ and slit roll is then rewound and a barcoded label applied to the reel.

This is where automated shrink sleeve production takes over.

The final parts of both job automation processes will return to the Cerm operator and the audience will be taken through steps including warehousing, job picking, shipping carrier allocation, customer notification and invoicing.

Tasha Ventimiglia, Labelexpo Americas event director, commented: ‘The Automation Arena is something we introduced at Labelexpo Europe last year and it proved such a popular experience that we are bringing it to Labelexpo Americas 2018 for the very first time. The main difference this year however, is that the shrink sleeve automation through the two Accraply elements on show are a world first. It’s therefore a unique opportunity for attendees to experience first-hand how the industry could evolve over the next decade and meet some of the companies at the forefront of this.’

Mike Fairley, Automation Arena lead and Labelexpo strategic consultant, added: ‘In an era of ever decreasing run lengths, production bottlenecks, plus shorter lead and delivery times, it seems certain that increasing automation of tomorrow’s label and shrink sleeve plants will become a necessity for their successful performance and profitability. The Automation Arena will provide an important showcase at Labelexpo Americas 2018 of just what is now becoming feasible.’

Fairley will also be hosting three Label Academy master classes that touch on a number of the key components being demonstrated at the Automation Arena, as part of the show’s comprehensive educational program. For master class attendees, the Automation Arena is an unmissable opportunity to see the theory in action.

Labelexpo Americas takes place September 25-27 at the Donald E. Stephens Convention Center, Rosemont, Illinois. The Automation Arena is free to attend for all Labelexpo Americas 2018 registered visitors.

Read a comprehensive preview of Labelexpo Americas 2018 in Labels & Labeling, issue 4, 2018

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.