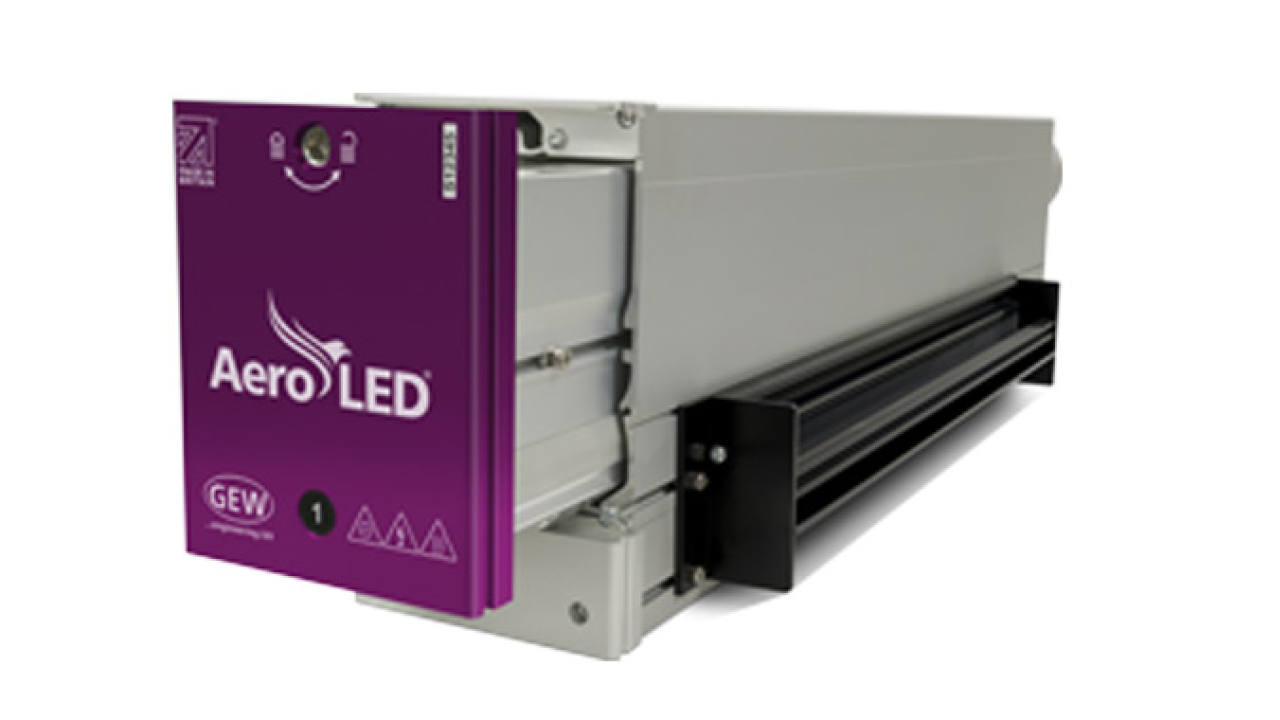

GEW highlights air-cooled AeroLED UV LED system

UV curing systems manufacturer GEW is showcasing the full product range, with a particular emphasis on its air-cooled UV LED system AeroLED, which is now ArcLED compatible.

AeroLED is a high-power system for full curing, printing, coating and converting applications up to 60cm wide. New at Labelexpo is an innovative design update that makes AeroLED compatible with GEW’s ArcLED system. Using the same fan and ducting arrangement as the industry standard E2C, customers have total flexibility to switch between arc and LED curing on any station. No filters are required due to the high redundancy, making maintenance a breeze and an AeroLED retrofit more cost effective than ever before. Moreover, any customers with GEW’s Rhino/RLT power supply platform can upgrade to LED within a matter of hours, by simply changing the cassettes and running a software upgrade.

In an AeroLED system, air is extracted by a single centralised fan sited away from the press. There is no need for integrated fans or electronics in the individual lampheads, which eliminates the high-pitched noise and risk of failure that these bring. AeroLED features the same LED chassis and core components as GEW’s LeoLED lamphead, for proven reliability. As with LeoLED, the lamphead has tough watertight seals to protect the LED modules from ingress and to make cleaning easy and safe.

AeroLED’s efficient optical design enables the lowest energy usage of all GEW products. This delivers, according to the company, energy savings of typically 50-70 percent, when compared to a conventional UV arc system. In addition to offering greatly reduced operating costs, printers upgrading to LED can free up a significant level of mains capacity, which can then be used to install new machinery and subsequently increase production capability. Two AeroLED systems have a lower electrical supply requirement than just one conventional arc UV system.

A further advantage of LED is its predictability and stability of UV output in the curing process. AeroLED delivers a step change in process control by ensuring stable UV output year after year, and eliminates the uncertainty of conventional UV lamps, reflectors and mechanisms to ensure consistent production quality. As is the case with all new GEW UV products, AeroLED uses GEW’s Rhino power supply and control range, for ultimate reliability with Industry 4.0 approved, IoT Remote Monitoring as standard.

GEW is also showcasing its water-cooled UV LED option, LeoLED. Launched in 2019, LeoLED delivers maximum power and UV dose for more demanding applications. Both UV LED models are built to GEW’s usual exacting standards, using state-of-the-art manufacturing techniques, for robust performance and reliability. Both are available with a five-year GEW system warranty, for peace of mind.

Robert Rae, managing director of sales at GEW, commented: ‘UV LED is no longer just a technology for the future, it has become an essential technology for the present day. This change has been driven by the recent and dramatic increases in global energy prices, creating an unprecedented demand for low-energy, sustainable LED solutions as well as improved ink technology and availability. Technological advancement is leading to ever more efficient and cost-effective UV LED products, as is demonstrated by the introduction of AeroLED. The opportunities are huge, and we are convinced that LED will soon become the dominant technology in our narrow web market.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.