Phoseon and Cyngient join forces for UV LED

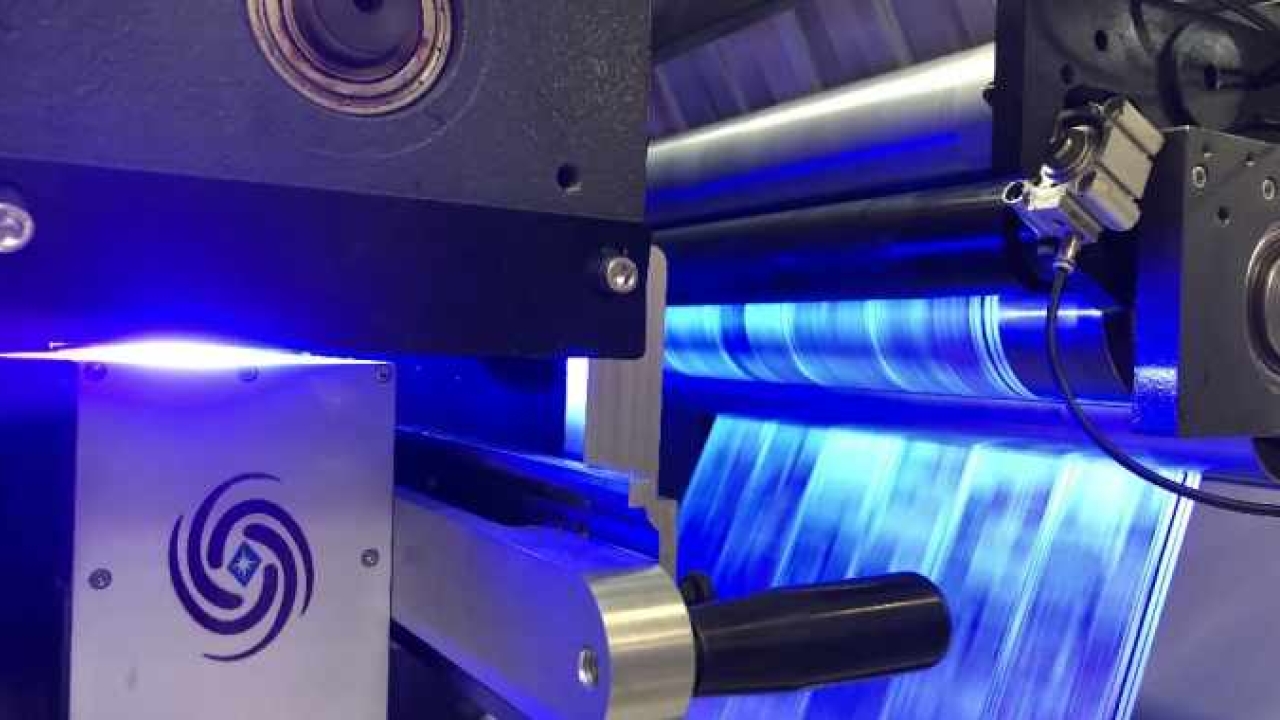

Phoseon Technology and Cyngient have join forces to develop adhesive technology optimized for label converters using LED UV curing systems on flexographic and hybrid presses.

‘Technical support from Cyngient allows Phoseon to offer customers faster and more efficient adhesive product support with predictable consistent performance,’ said Andrew Wasserman, managing partner at Cyngient.

Cyngient’s HYPERcure LED and UV adhesives combined with Phoseon’s LED curing technology are said to offer customers peace of mind for turnkey cold foil and lamination products with stronger bonds and better cold foil transfer. These adhesives deliver more predictable results when paired with LED curing systems.

Combination of both technologies is said to double production speeds versus UV mercury, improve through cure, better cold foil (3pt at 500 FPM) transfer and stronger bonding for structural lamination adhesives on label, tube and industrial applications.

The family of HYPERcure adhesives demonstrates improved results for cold foil transfer for self-wound, unsupported films, shrink films and paper where better results are required and often when no other product works. They are optimized for speed, cure, flexibility, and high shrinkability, eliminating adhesive cracking for shrink film products and increased bond strength where required with the low energy output of LED /UV lamps.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.