Schober redesigns SL 106

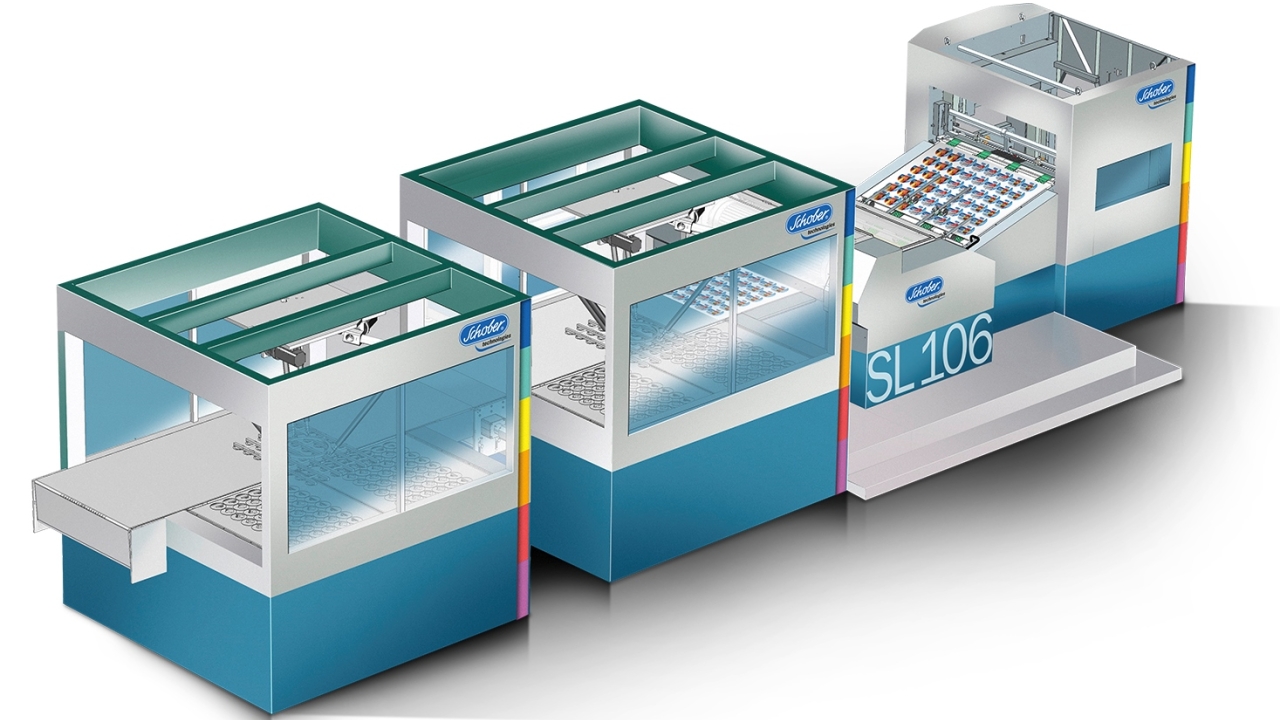

Schober has redesigned its Sheetline SL 106 rotary sheet-fed converting line.

The Sheetline SL 106 is equipped with a high-speed belt stream feeder combined with suction head technology and a heavy duty die-cutting station, as well as a robot-automated stacking, counting and piling system.

Most of the features which have proven their efficiency in the web-fed die-cutting machine such as the pre-set and calibrated cutting pressure adjustment, high-precision bearing assemblies and housings for low temperature running, vibration-free design and micrometric die wear compensation adjustment (GCS) have been integrated in the die cutting station of the Sheetline SL 106.

In addition, the converting station is equipped with a vacuum controlled magnetic cylinder tool and the new and unique gripper sheet guiding system which ensures high-precision finishing of pre-printed sheets. The products are separated from the matrix immediately after the cutting process and redirected to the robot-automated stacking unit by a conveyor belt. Magnetic dies guarantee a set-up time as well as the highest productivity, even for short runs, the company claims. Further, the design of the die-cutting station and its accessibility allows the possibility to integrate additional finishing tools at a later stage.

The robot-automated stacking system is capable of handling different types of products combined within the same printing image. These can be heavily nested and can be a combination of large and small products.

Product specific fast exchangeable pick-up plates collect products at synchronized speed and stack them non-stop into a twin piling cassette system.

The Sheetline SL 106 is designed for a sheet size of 106 x 78cm and a foil thickness starting at 50 microns.

The system was launched in 2012.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.