Stork Prints appoints Italian distributor for RotaPlate screen

Stork Prints has appointed Milan-based paper converting and specialist printing agency SO.MA.CA to distribute the Dutch company’s reusable nickel RotaPlate screen in Italy.

Wim Zoomer, account manager at Stork Prints, commented: ‘We are delighted to announce this distribution agreement with SO.MA.CA. The company not only offers proximity to our customers, but has a long-standing record of expertise in narrow-web markets. This partnership will ensure our Italian customers have access to a reliable, highly acclaimed screen and first-class technical and sales support, too.’

The electroformed, non-woven RotaPlate program, suited for non-Stork systems, covers the full range of rotary screen applications, from fine linework to Braille and tactile image features. SO.MA.CA. offers the RotaPlate range in both rolls as well as pre-cut and punched sheets.

Specifically for non-Stork systems, RotaPlate is said to offer greater strength, handling qualities and resistance to damage during printing. Furthermore, its hexagonal structure allows up to 40 percent greater hole-counts in a given area compared with alternative meshes, making the screen ideal for high-detail reproduction.

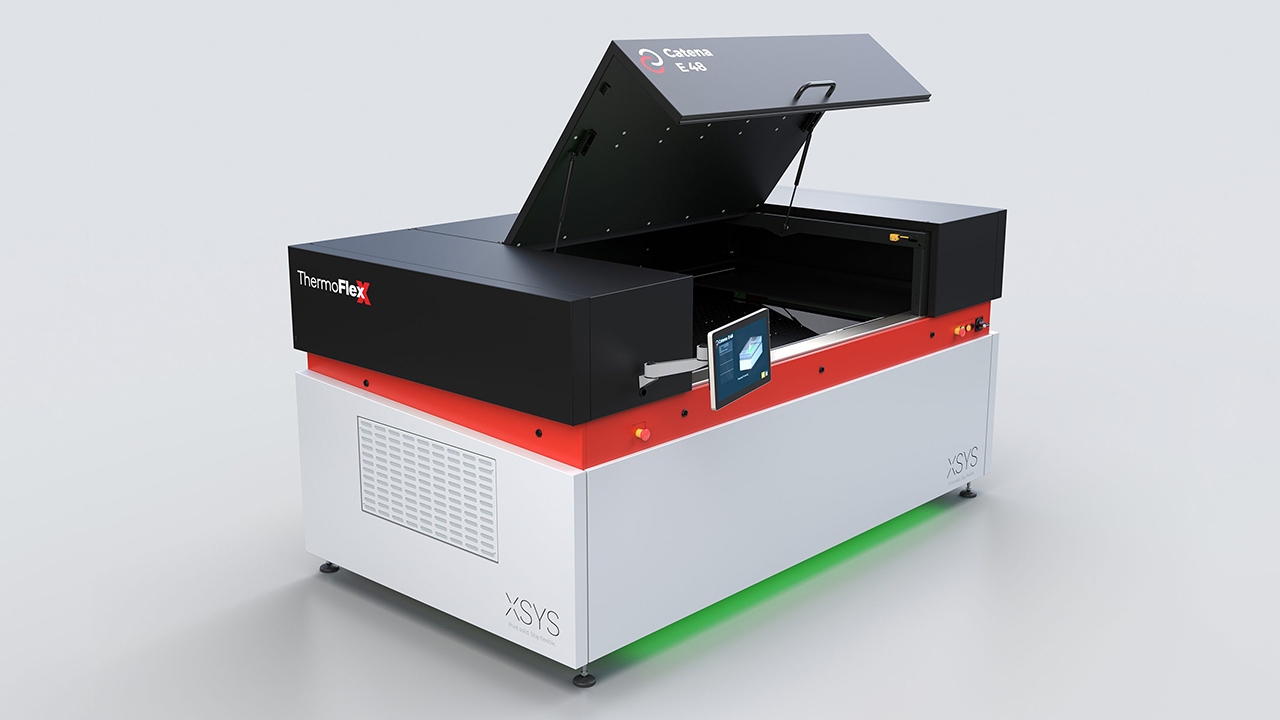

As an alternative to conventional exposure, Stork offers a fully digital way of pre-production for RotaPlate users, known as ‘direct laser exposure’. With the company’s newly launched table-top rotaLEX 6610F system, a laser exposes the emulsion of the non-image (negative) areas, enabling the unexposed areas to be removed with ease. The screen is subsequently ready for insertion into the printing station. This method avoids the need for film, ablative film or ablative plate processing.

Click here for more stories about Stork Prints on L&L.com.

Click here for more stories about SO.MA.CA. on L&L.com.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.