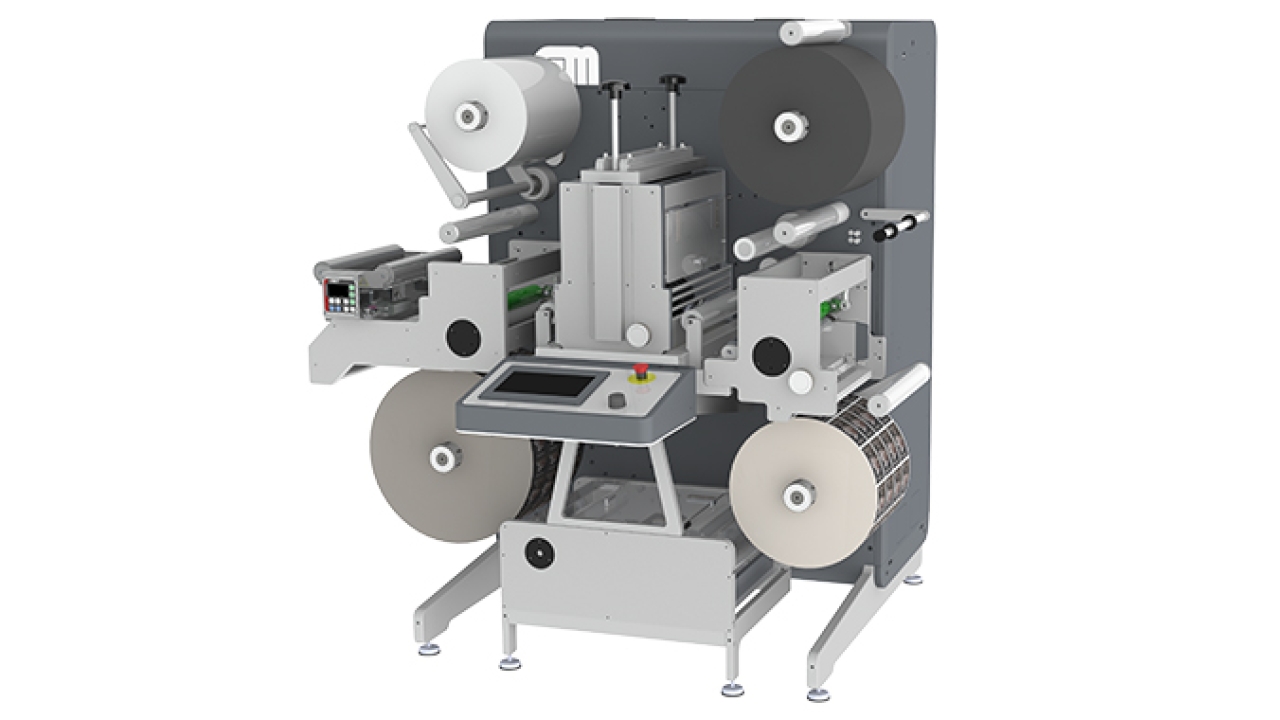

GM launches DC350Nano compact converting unit

Grafisk Maskinfabrik has expanded the range of its wider web machines with GM DC350Nano, ultra-compact and cost-effective unit for self-adhesive lamination, semi-rotary die-cutting and length slitting of label web widths up to 350mm.

The new unit offers the same benefits as the older 330mm web width Nano model, but also features increased speed in semi-rotary mode of up to 45m/min (148ft/min) and comes in a new design consistent with the entire 350mm line.

The DC350Nano is the most compact unit in GM’s series of label finishing machines, measuring only 1600 x 1600 x 1700mm (63 x 63 x 67in). It is built on a solid 20mm (0.8in) metal frame for vibration-free operation of the servo motors that drive the web. Lamination, die-cutting, slitting and rewinding come as standard, with the option to add online support and remote service, buffer module for in-line converting, Kocher+Beck Gap Master, advanced stripping roller system and extra mark reader. Webs in widths up to 350mm (13in) and a max substrate thickness of 200 microns can be converted.

‘We continue to push the boundaries and further develop our product line, and as digital label printing continues to grow, label printing companies are realizing the need for all-inclusive systems that provide value-adding features for producing fully finished labels,’ said Uffe Nielsen, CEO of Grafisk Maskinfabrik. ‘This compact, but versatile unit is ideal as a converter for a small digital press or as a backup to an existing finishing line, and it fits nicely into our 350mm portfolio.’

The new machine can be set up as an in-line extension to any digital label press, allowing the web to continue directly into the converter, or it can work as a standard offline unit. With semi-rotary die-cutting, lamination and a genuine pneumatic knife box with crush knives, it offers the majority of the equipment needed for short-run digital label production, but it can also work as a simple die cutter for the production of blank labels.

The new machine can be supplied with full connectivity through GM’s VPN Gateway technology for remote diagnostics, service and support using a secure internet connection. This establishes access through the firewall of the existing wired network infrastructure to provide remote access for on-demand, real-time servicing.

The DC350Nano is another product in the new wider line of machines, which also includes the DC350 premium finishing line, the DC350MiniFlex compact converting line, SR350 slitter rewinder and the IR350 multifunctional inspection rewinder.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.