OPM Europa and DG Press develop printer-to-container technology

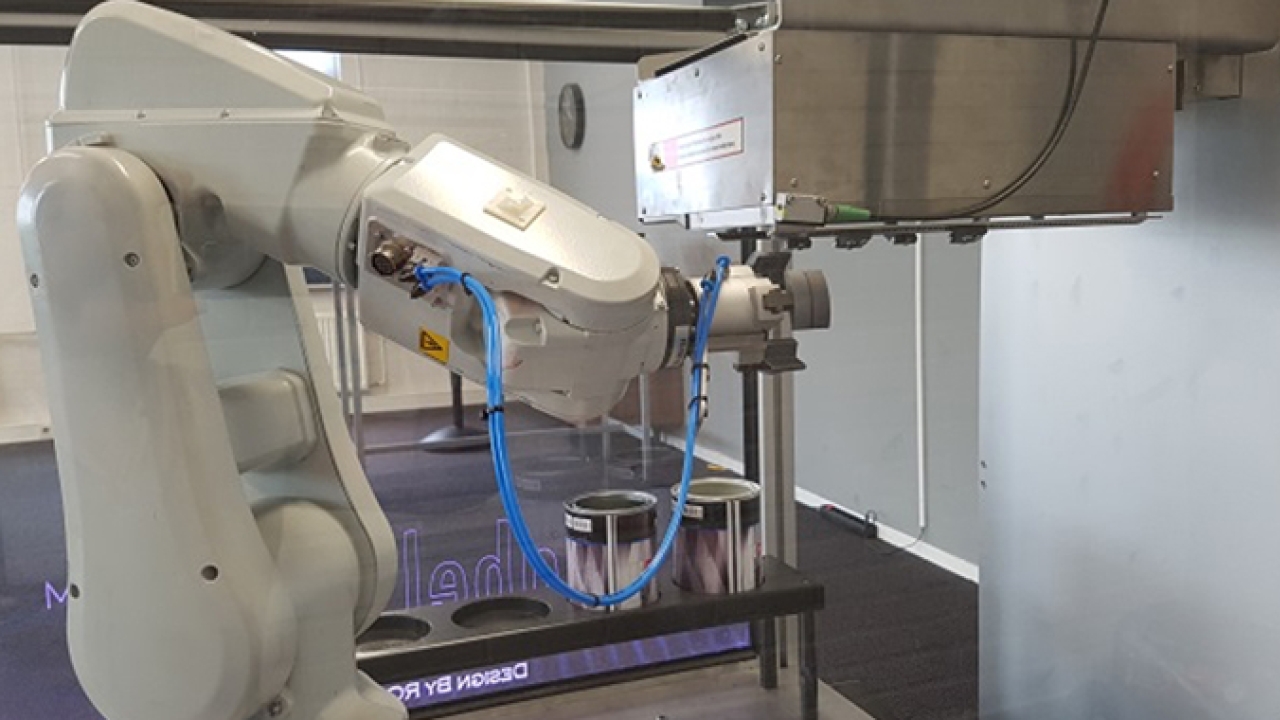

OPM Europa has partnered with DG press to develop LabelSaver, an inkjet printer using water-based ink for direct-to-object printing of containers and bottles. It will be manufactured, installed and supported by DP press.

Direct-to-object inkjet printing of cans and bottles is an application with a very strong growth. L&L has recently published an article about the world’s largest brewery, which has been testing this technology since 2014 on a small batch of products. This technology offers a sustainable option with water-based inks, which are safe to use and friendlier to the environment than UV, solvent or liquid toner inks.

According to OPM, the LabelSaver is the first device enables direct printing of jerry cans, paint cans and HDPE/LDPE bottles with aqueous inkjet inks. It is said to offer environmental and economic advantages with achievable cost savings for short to medium production runs. OPM also claims that a positive return on investment can be realized in less than six months.

‘We have been researching the market for water-based inkjet technology for years and concluded that Memjet has the most sophisticated and suitable solutions for this application, said Dursun Acun, owner and managing director of OPM Europa. ‘With the LabelSaver, we can 360-degree print up to 3,000 cans per hour in full color. Painting cans is challenging, as it demands print quality and chemical resistance at the same time. The LabelSaver is versatile and can easily be adapted for other size and materials of containers.

‘The logistical cost savings for the customer are enormous; no need to order and wait for your labels, no need to align production volumes and the number of labels of many kinds, and of course print design changes can be made on the fly with no need for new printing plates. Now you can print on demand and to order volume at the time you start filling your goods.’

Remko Koolbergen, director of DG press added: ‘DG press is a well-established machine manufacturer of high-end hybrid printing presses with an excellent service reputation worldwide. We know the label market very well, and the trend to eliminate pressure sensitive labels is strengthening. We believe in the near future labels will be increasingly replaced by inkjet object-to-container printing. For our future business and our customers’ business, we want to build and support this unique featured LabelSaver. We engineer, install and service the machine and its controls anywhere in the world. We believe the LabelSaver will give a strong positive contribution to the digital print business direct-to-object.’

‘We are delighted to see Memjet as the technology of choice for this type of application,’ added Donald Allred, VP of packaging at Memjet. ‘Direct-to-shape digital inkjet printing provides many manufacturers with the flexibility and benefits of digital printing while providing a positive impact on their profits. Congratulations to Dursun and his associates for diligently working to bring this new capability to the market.’

The LabelSaver will be on show during this year’s edition of drupa 2020 between 16-26 June in Düsseldorf, Germany at the DG press stand where the company will be providing more information on the possibilities of digital direct-to-object printing.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.