Uflex launches extrusion lamination machine

Uflex has launched the EL-1300 extrusion lamination machine.

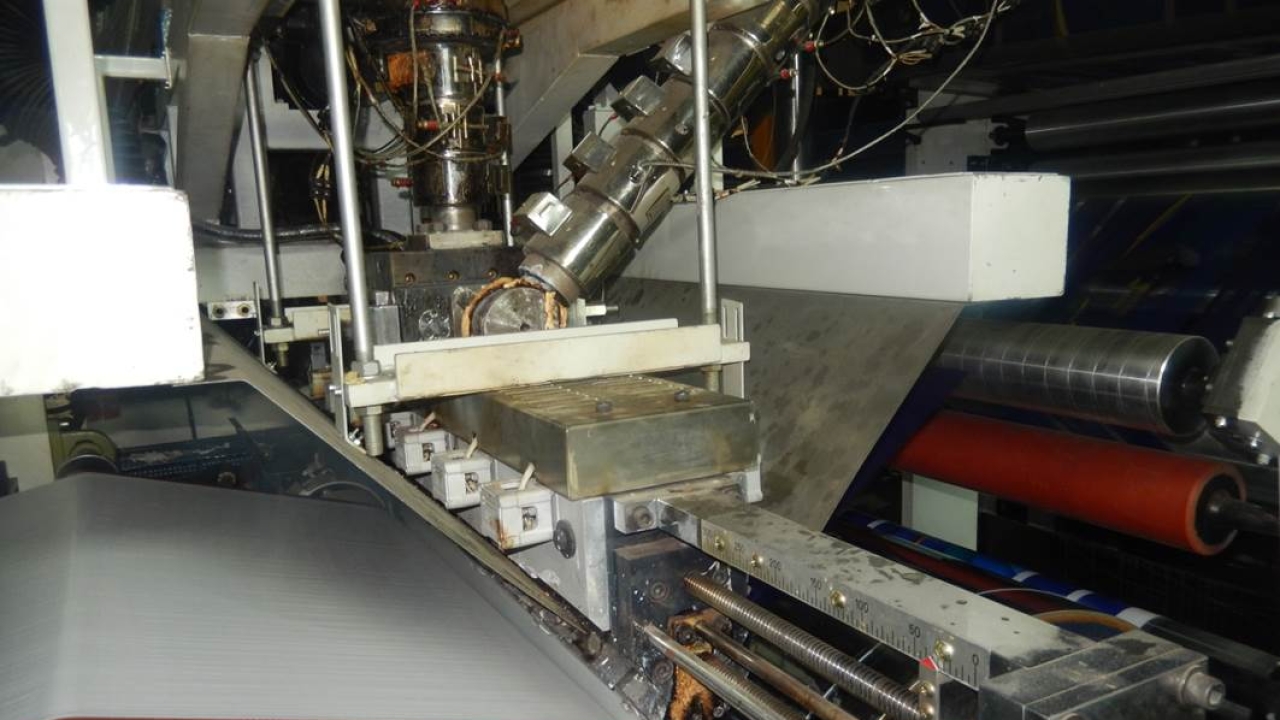

The machine operates at speeds of 250 m/min. Other features include independent drives for all segments of the machine, T-die with internal duckling and lip opening up to 1mm, motorized three axis movement of carriage for air gap setting, and chamber type doctor blade for anchor coating.

The machine is equipped with turret type unwind and rewind, and AC vector grade motor with digital AC vector drives. Design of the lamination drum maintains even temperature across the width of the machine. The laminator includes a corona treater and optional sleeve-type coating nip.

Ashok Chaturvedi, chairman and managing director, Uflex said, ‘Our USP lies in the very fact that we are a fully integrated flexible packaging solution company. We can offer laminates as rolls and pre-formed pouches, and machines that can form packs our of those rolls, fill the product and seal it. We also offer a wide array of printing and lamination machines that are capable of carrying out high precision converting processes to make these laminates.’

Uflex is a fully integrated operation from PET chip manufacturing for polyester films to speciality packaging films, laminated flexitubes and bags. The company also manufactures rotogravure printing cylinders, flexo-polymer plates, elastomers and sleeves, inks, adhesives, coatings and polyols used in the converting process.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.