Digital presses take center stage

It has been three years since the last Labelexpo show so there was much to catch up on, and a clutch of world firsts greeted the 13,500 Americas 2022 show attendees.

This Labelexpo in many ways represented a turning point in the relationship between flexo and digital printing. Up to now, digital has been seen mainly as a way for converters to offload their short-run work, allowing the flexo press to handle the medium-to-long runs. But a new generation of digital presses developed over the pandemic years is now challenging that assumption, matching the speeds commonly reached by flexographic presses in real-world production environments.

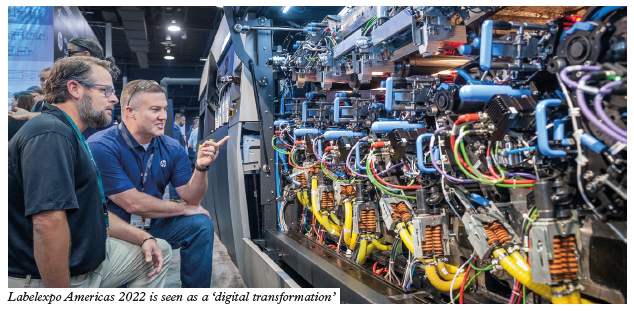

Expectations were sky-high after HP Indigo announced that it would be showing its new V12 press at Labelexpo Americas, and after a hair-raising journey to Chicago from the New York docks that involved lost cargo and multiple teams setting it up in time for its debut, the V12 arrived safely at the show – the first time this press has been seen outside of HP’s demo and production building in Israel. It was certainly worth the wait, printing at 394ft/min (120m/min) in six colors at 1,600 DPI, fully matching the productivity and quality of flexography.

Expectations were sky-high after HP Indigo announced that it would be showing its new V12 press at Labelexpo Americas, and after a hair-raising journey to Chicago from the New York docks that involved lost cargo and multiple teams setting it up in time for its debut, the V12 arrived safely at the show – the first time this press has been seen outside of HP’s demo and production building in Israel. It was certainly worth the wait, printing at 394ft/min (120m/min) in six colors at 1,600 DPI, fully matching the productivity and quality of flexography.

The V12 makes use of HP Indigo’s new LEPx technology, which replaces the intermittent digital plate cylinder found in all previous HP Indigo label presses with a continuous rotary blanket, building up the colors sequentially and then depositing the finished image onto the substrate. There are a total of 12 color stations, any six of which can be engaged for full-speed printing. If more than six colors are required two rotations of the blanket are required, halving the print speed. It is expected that most standard jobs will be covered by six colors.

Both near-line and in-line finishing systems are under development by HP Indigo’s long-term converting equipment partner ABG.

Also present on the HP Indigo stand was Maximilliano Martino, chief technology officer of the global All4Labels group, which is the first beta site for the new press at its Hamburg, Germany plant.

Inkjet technology is also closing in on flexo productivity. Durst Group gave the global tradeshow premier to its 20in wide Tau RSCi, printing four colors at 100m/min (328ft/min).

The RSCi was shown in a roll-to-roll configuration incorporating two UV flexo units, one before and after the digital print engine – allowing, for example, a first down white and varnish to be applied.

The press was demonstrated with Durst’s own workflow and analytics software allowing real-time machine monitoring. Optional is Durst’s Smart Shop software, which enables web-to-print operation.

Dantex Group launched the next generation of its Pico UV inkjet digital press series. Four different modular print platforms will be available from entry-level to full hybrid, 8-color and high-speed models.

Developed over the last two years, the range includes the PicoColour HD 1200, PicoJet 1200, PicoJet 1200i, and the flagship high-speed PicoJet 1200s which was on the Dantex stand. The presses use Ricoh’s latest inkjet print heads.

Each press in the series is based on a modular design incorporating in-line finishing and a wide format touch screen which takes up two panels of the press side frame and allows easy access to all press parameters. The PicoJet 1200s launched at the show was configured with one flexo unit after the digital engine, a lamination unit and a slide-in/slide-out rotary die-cutting station.

The press is designed to register against the die station, allowing rapid end-to-end job setup with minimal waste.

Dantex’s SuperWhite and DecoTactile technologies are included as standard. SuperWhite ink delivers up to 92 percent opacity in a single pass, while DecoTactile can create a wide range of textured embellishments. Additional OGV color options are now offered, extending the color gamut to a claimed 96 percent of Pantone colors at a Delta E of 3 and below.

The Pico press software has been strengthened through partnerships with leading workflow suppliers, including Esko.

Domino showed for the first time its N730i UV inkjet press, the first Domino label press to use the 1,200 DPI Bitstar print heads developed by parent company Brother Group.

The N730i is configurable with up to seven colors (CMYK+OV+W), which covers up to 92 percent of the Pantone color range. Roll lifts at the unwind and rewind support media rolls up to one meter in diameter.

Flexo stations can be retrofitted before and after the digital print engine. The fi

rst station could be applying a primer for more difficult media types and the post-digital unit applying varnish, a brand spot color, or flood white for shrink sleeve applications.

The established N610i continues to be sold, and was present on the Domino stand, alongside the K600i dual bar digital UV inkjet printer. The K600i allows variable data printing at speeds of 492 ft/min.

JetFX launched a ground-breaking 30in-wide print bar at the show, printing at 100m/min using both eBeam and UV inks. JetFX was showing examples of embellishments on pouches and shrink sleeves as well as PS labels.

Also launched was the JetFX Visualizer software, which allows users to preview the effects of the embellishment in detailed full relief. The system holds a pre-loaded library of embellishment effects, including both foiling and varnishing.

The digital foil is of exceptionally high-quality due to a two-step process with a pre- and post-cure using a cocktail of different photoinitiators at different wavelengths. This results in excellent edge cure, avoiding the edge lift, which often characterizes digital cold foil applications. Varnish can be applied in multiple thicknesses in a single pass.

Xeikon also had a major inkjet announcement at the show. Xeikon/Flint Group is claiming a first for its LED-UV inks, which can be used on any Panther inkjet press installed since 2017 after an LED lamp retrofit. Xeikon says this reduces energy consumption by 20 percent during printing and more during standby when the lamp is switched off.

WATER-BASED INKJET

There are enormous potential benefits in using water-based inkjet in migration-sensitive applications such as pharma labels and food packaging, and this has become more practical with the development of pigment-based ink systems.

Labelexpo Americas 2022 saw a number of new water-based systems launched using these inks.

Arrow Systems launched a new digital press using Memjet’s established Duraflex pigmented water-based ink technology. The ArrowJet Aqua 330 is designed to print labels, flexible packaging, blister foils and shrink sleeves at 1,600x1,600 DPI resolution and speeds of 150ft/min. For print-and-cut applications, the company showed its ArrowJet Nova 330R, which can use either blade or laser-cutting technology.

Anytron launched its Any-Jet III, a 13in (330mm) press also using Memjet aqueous inkjet technology, which is configured inline with laser die-cutting and an optional thermal lamination unit. Print speed is 45m/min at 1,600 x 1,600 DPI resolution.

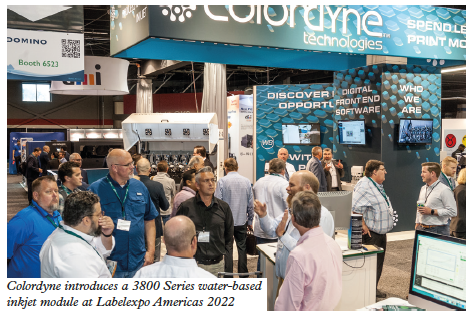

Colordyne Technologies specializes in retrofit inkjet modules for flexo presses, and its major introduction at this show was the 3800 Series water-based inkjet module, targeted at food and pharmaceutical packaging applications and using Kyocera printhead technology.

Expanding its strategic partnership with Kao Collins, the 3800WB module leverages Colordyne’s proven 3800 Series UV engine design and Kao Collins’ LunaJet inks to create a system capable of printing on labels, plastic flexible film packaging and other non-porous substrates.

Colordyne was also promoting its new LED-UV inkjet integration module and announced a tie-up with Fiery to use its Fiery Impress server to drive both UV-LED and water-based retrofit modules.

Epson showed its SurePress L-4733AW water-based resin inkjet press, the successor to the highly successful L-4533AW.

Konica Minolta had a technology preview of its PKG-1300 digital corrugated/carton box printer, targeted mainly at the e-commerce packaging market. The press prints at 27m/min at 1,200 x 1,200 DPI with pigmented water-based inks on uncoated cartonboard and corrugated stock up to 51 x 63in (1,300 x 1,600mm). The PKG-1300 can be supplied as a fully automated line including an auto feeder and stacker. The launch date is Q1 2023.

TONER DEVELOPMENTS

With so much focus on inkjet, it is easy to overlook the advances being made in dry toner technology. Xeikon launched a swathe of new products which will revolutionize what can be achieved with its Cheetah-series toner presses.

First up is a new dry toner technology the company calls Titon. Like Xeikon’s ICE toner, Titon is qualified for direct and indirect food contact, but in addition incorporates protective layers, which provide heat, sunlight, water, scratch and scuff resistance.

As well as durable food-safe labels, a key market Xeikon sees for Titon is paper-based flexible packaging - stand-up pouches in particular - now being specified by many brands as an alternative to plastics-based constructions. This would allow paper to be used as a mono-material without a plastic or aluminum barrier. Its high level of mechanical resistance would mean no requirement for a protective varnish or laminate, and chemical resistance would make it ideal for products like wet wipes. Titon can be readily removed from paper products during the recycling process.

Titon toner will not run on the current generation of Cheetah presses, so we will need to wait for the next generation of Titon-enabled press technology.

Xeikon also unveiled new metallic silver and gold toners to run on the fifth print station of its Cheetah presses, allowing converters to add metallic embellishments without the need for adding conventional processes like cold/hot foil on the converting line.

For adding tactile effects on labels for beer, beverage, food, and health & beauty markets, Xeikon introduced its haptic printing process, which helps converters make significant time savings by avoiding any modifications to the pre-press files.

Konica Minolta continued a successful strategy of repurposing its commercial-market toner engine to the narrow web label sector, allowing Konica to take advantage of economies of scale in manufacturing, distribution and support.

The 13in-wide AccurioLabel 400 is the latest in this press series, adding a highly opaque white toner to the previous CMYK and upping press speed to 139ft/min (40m/min) in 4-colors at a print resolution equivalent to 3,600x1,200 DPI. Running with the white station drops the speed to 20m/min. The toner reservoir allows for 3,000 meters of continuous printing, and the unwind can take rolls up to 800mm. The Intelligent Quality Optimizer (IQ-520) software enables real-time control of white toner opacity and color using an inline spectrophotometer developed by Konica Minolta.

The AccurioLabel 400 is supplied with the AccurioPro Flux software package for the imposition and ganging of labels, which includes pre-flight and color management modules. A Kodak (Creo) controller for high-volume VDP is also available.

The press also includes as standard a sensor kit for registration to pre-printed media. A partnership with GM makes available the DC330 Mini all-in-one compact label finishing machine for either in-line or near line operation.

Also on the stand was the AccurioLabel 230 which put Konica Minolta on the narrow web map, along with a GM DC330Mini finishing unit with hot foil, screen embellishment and optional turret rewind. Konica says there have been more than 1,000 global AL230 installations since the company entered the narrow web market in 2016.

DIGITAL TRANSFORMATION

While there were no flexo presses at Labelexpo Americas 2022, there was still a lot of interest from visitors in finding out about new flexo developments, and flexo presses were actually sold at the event.

Mark Andy, one of the founders of the narrow web flexographic industry, was promoting the theme of digital transformation, presenting three narrow web hybrid presses for label production.

The show was the world premiere of the Mark Andy Digital Pro Max press. Compared to previous Digital Pro models, the press is faster, has a lower cost to print, includes toner white, and can be upgraded with flexo and converting modules. The DPro Max press is based around the latest Konica Minolta AL400 print engine and offers a maximum speed with CMYK of up to 160 ft/min (49m/min). The press can be configured with up to three flexo stations before or after the digital engine. Cold foil and lamination stations can be added at any time.

For printing on the back of the liner, the press can be equipped with a turn bar and upgraded with Mark Andy’s semi-rotary vertical die-cut unit. The toner white adds transparent and metalized substrate capability without the need for a flexo station.

This was also the first trade show outing for Mark Andy’s Digital Series iQ press. The press is built around a Domino N610i UV inkjet module integrated with Mark Andy’s Evolution Series press platform. The Digital Series iQ can be configured with up to seven UV inkjet colors - CMYKOV+WW. Hybrid converting components include flexo print stations, semi-rotary die cutting, a rail system for web turn bars or cold-foiling unit, and inline slitting, as required. The press offers 600 x 600 DPI resolution at up to 70m/min (230ft/min). Live demos included VDP printing on white gloss BOPP foil and a Kombucha label printed on chrome metalized PP foil.

The established Digital Series HD press was also on show configured with four flexo units, in-line varnish and die-cutting.

An important highlight was the launch of Mark Andy’s sMArt link software, a real-time on-press data collection and press monitoring system. sMArt link ties shop floor equipment together in one analytical tool that is accessible from anywhere with an internet hookup. It can be accessed through a cloud-based platform and is suitable for new and existing Mark Andy presses, both flexo and digital/hybrids. Mark Andy says other manufacturers’ equipment can also be tied into the system. sMArt link can also be integrated into wider factory management systems.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.