The pandemic’s effects on sustainability

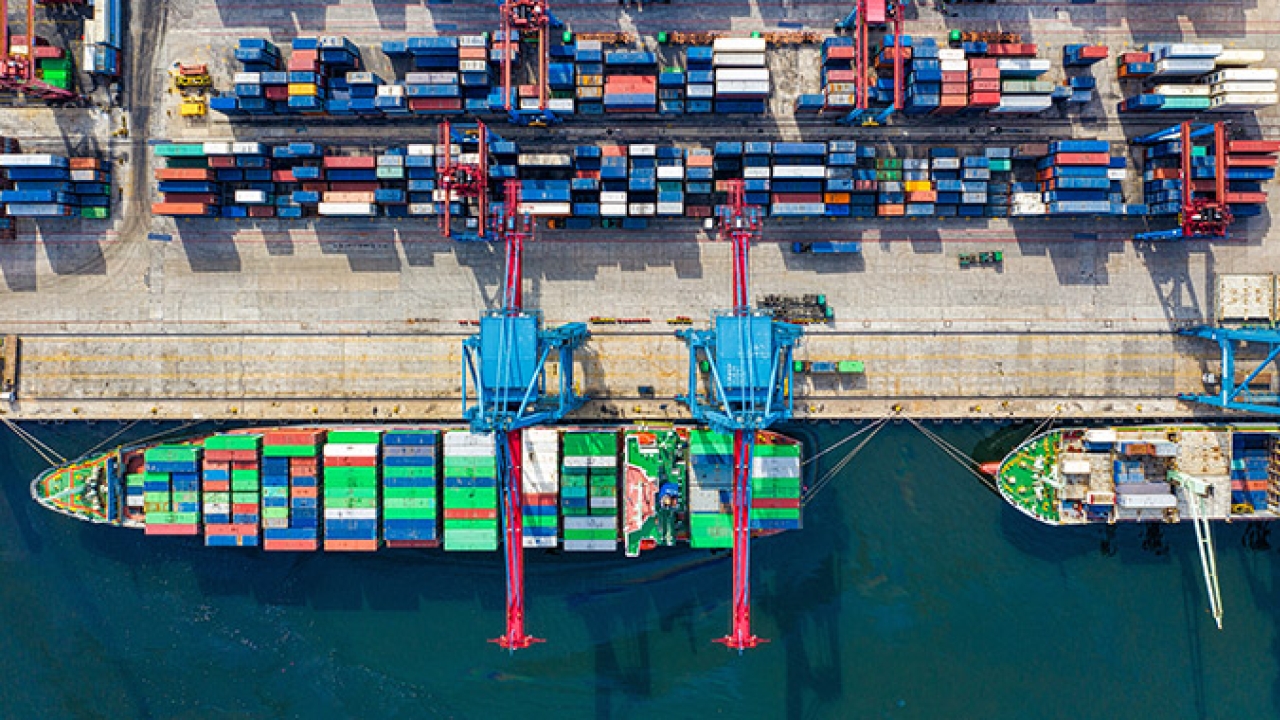

The huge shortages in CPG has created a Catch-22: brands don’t want empty shelves in stores or out-of-stock issues online, but they don't want to over-produce, either. They want just enough product and packaging to meet demand, while having enough product for ‘just in case’. (Just in case of shipping interruptions, spikes in Covid cases, weather events – you name it). It’s a balancing act of planning for efficiencies and contingencies.

How much is just enough?

How does supply chain disruption uniquely impact packaging? First, conventional printing typically requires long lead times. In the Pandemic Paradigm, brands need to get products on the shelves (and in warehouses) faster. That means creating print and packaging faster, too – only not too fast and not too much. The old equations for supply and demand simply don’t apply. The new formula needs to determine how much is just enough.

Which leads us to the topic of sustainability. When brands produce too much, it causes storage issues, waste and the potential for products (and therefore, packaging) to become obsolete. For example, if a brand changes its formula, flavor or branding, they have to discard the previous packaging. That’s not only expensive, it’s also wasteful and in direct opposition to many brands’ environmental mission and their customers’ desires to do business with environmentally-conscious companies.

Can digital print fill the gap?

A primary concern of supply chain disruption is, of course, the risk that brands may lose customers forever. If brands don't have enough product to sell or ship, their customers will buy a different product that is in stock, and may never return. So as brands are figuring out the balance of just enough and just in case, converters have an opportunity to help them navigate through it.

How can mass production and smaller print runs work together? One option is digital printing, which can fill the gaps when there are supply disruptions. Digital printing can also minimize waste, because brands can print the fewer quantities they need. Additionally, many digital printing OEMs are committed to reaching carbon neutrality and supporting the recyclability of their printed products by supporting the de-inking processes. While liquid toners are 94 percent de-inkable, some dry toners are 100 percent, which helps the viability of that recycled substrate. If brands can address these issues within the packaging manufacturing process, that's an environmental benefit and, for many consumers, a reason to switch brands or remain loyal.

Packaging’s responsibility

Brands and their packaging print partners have a duty to create responsible packaging beyond end-of-life recyclability. The dilemma for brands is balancing that responsibility with manufacturing costs, product margins, brand positioning and differentiation. Often, it can be more expensive to make a sustainable package than it is to make a less sustainable one. So brands have a decision to make: do they absorb the cost increase or pass it on to the customer? How will consumers respond? After all, it's one thing for consumers to say that they would pay more for a brand with sustainable packaging1; it's an entirely different thing to actually pay more!

Brands can also look at the cost increase through the lens of their mission and marketing strategy. That is, if the sustainable packaging helps the brand acquire new, environmentally-conscious customers, is the additional cost reasonable? In the Pandemic Paradigm, where shoppers are already more constrained, it’s easy to see why brands may be hesitant to raise their pricing. Time will tell if consumers are willing to put their money where their values are.

Digital printing, just-enough and just-in-time inventory is a solution of both efficiency and sustainability for the supply chain issues we are experiencing. Bottom line: if you're a converter and you're not addressing this, you need to. If you’re a brand and you’re not addressing this, rest assured that another brand is.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.