Linerless labels and their application

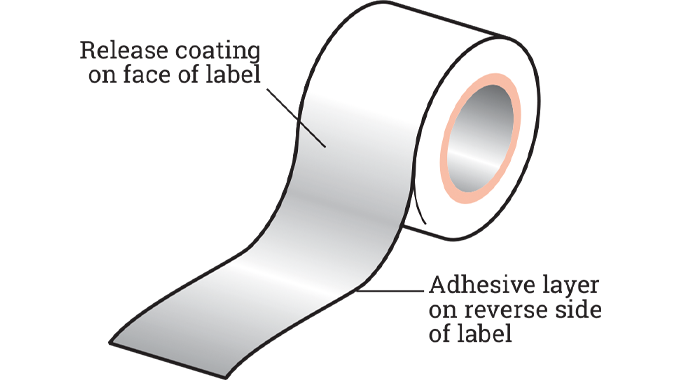

Conventional pressure-sensitive labels consist of a face material, an adhesive and a siliconized release liner backing that functions as a carrier for the label and protects the adhesive layer during handling, printing, finishing and right up to the point that the label is ready to be applied.

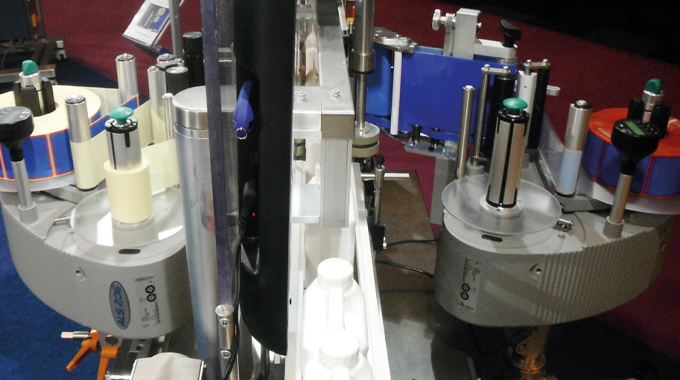

Applicators and labelers for conventional pressure-sensitive labels need to peel away the backing release liner for each label to be dispensed and successfully applied to a container, product or pack. The liner then needs to be disposed of as waste. Conventional pressure-sensitive laminated labels like this produce the highest waste levels of any packaging component with over 50 percent lost during conversion and final end-use application.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.