A look at digital drop-on-demand color label presses

Having briefly outlined some of the key elements of digital printing technology in previous articles it now becomes possible for the label converter planning to invest in digital on-demand color label printing to look at some of the main technologies, presses and suppliers on the market today and have an indication of their comparative performance in terms of printing technology, front end, resolution, etc.

Decisions to be made include:

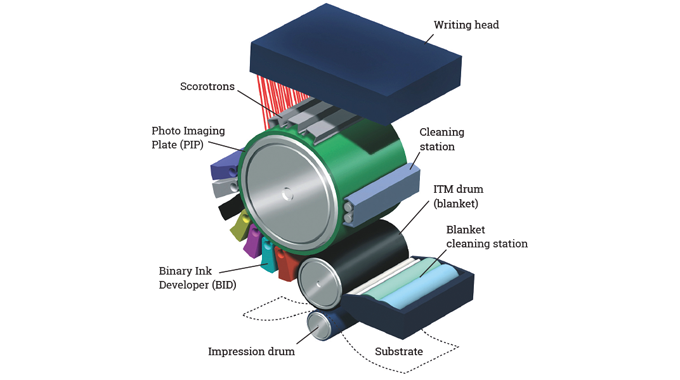

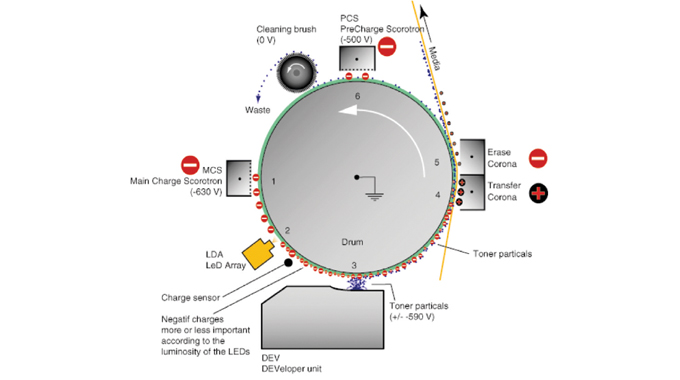

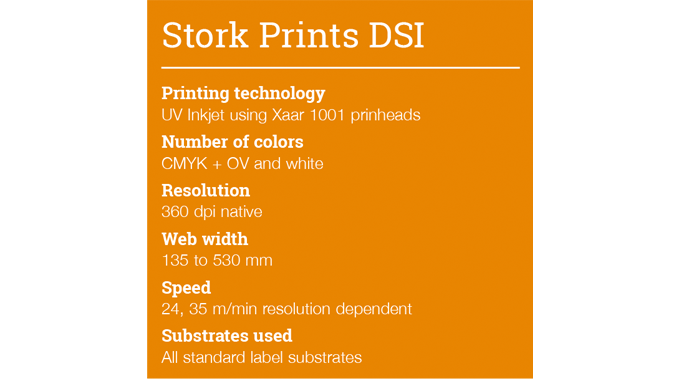

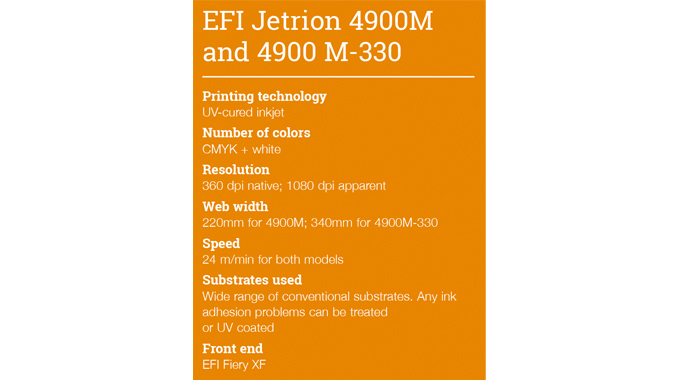

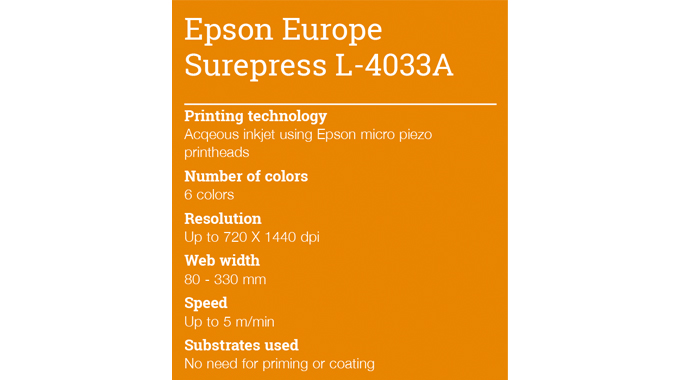

What digital printing process to invest in, e.g. liquid toner, dry toner, UV inkjet, water-based inkjet?

What print resolution will best meet the converter customer end-user requirements?

What web/print width is required? Does this need to fit in with existing analog press widths?

Do some or all substrates require a top coating or surface treatment?

Are there any substrates commonly used by the converter that are not suitable for printing with the particular press technology?

How many colors/print stations are required? CMYK, CMYKOV, extended color gamut?

Do the print jobs produced need a dense white, e.g. for printing on clear materials?

Is the press speed/throughput important?

Once the press is installed, are there other costs to consider, e.g. click charge, service charges, head replacement, etc?

Does the press Digital Front End (DFE) need to be compatible with existing pre-press and workflow?

Will it be necessary to upgrade or invest in a more sophisticated MIS system to better manage workflow?

What type of work will the press be expected to achieve? Multiple colors, CMYK only, UL approved, food contact, over-varnished, etc, and what are the main markets it will need to produce for – food, wines and spirits, personal care, pharma, industrial.

What are competitors using for this work?

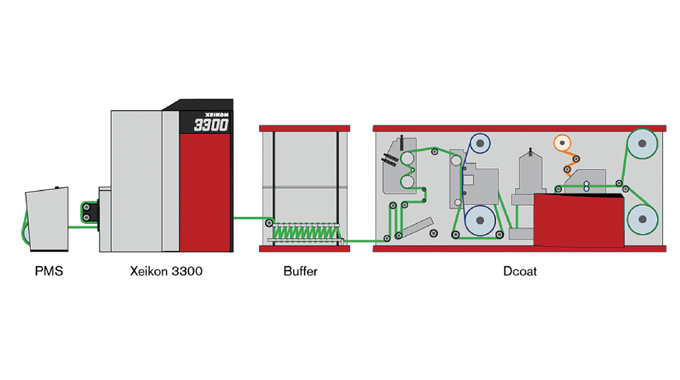

Does finishing need to be in-line or off-line? What finishing options will be needed, e.g. die-cutting, varnishing, embossing, foiling, etc. What additional investment will be required to finish the labels?

Can existing analog tooling be used on the digital print finishing line?

Does the volume, variety and sizes of work to be produced make laser die-cutting a viable finishing option?

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.