Systems for optimum drying and curing

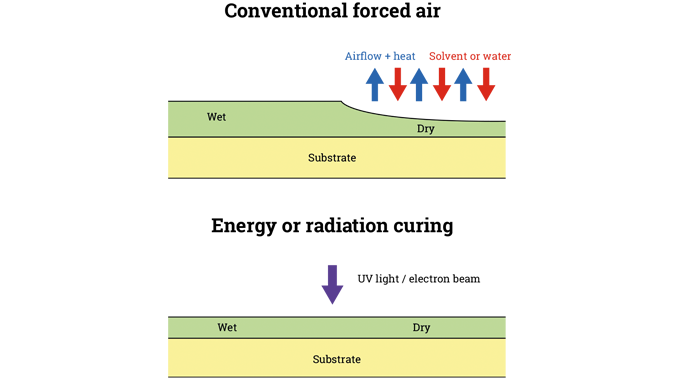

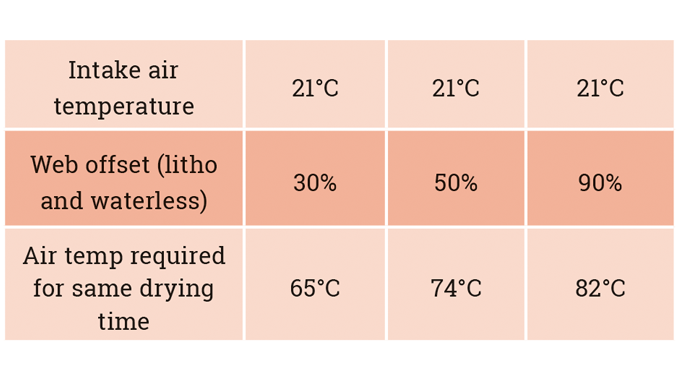

Optimum ink drying and curing is the key to faster press speeds. In the narrow and mid web in-line press sector, the web is moving at speeds up to 200m/min, and it is critical to fully dry the ink to avoid set-off of ink between the layers on the reel (see Figure 4.1).

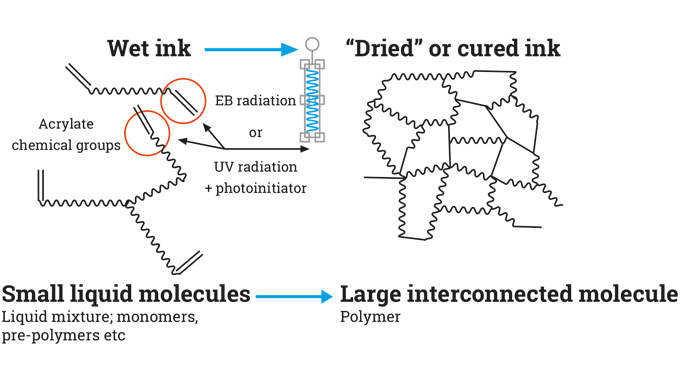

In UV flexo printing, due to the press configuration and ink characteristics it is normally necessary to dry the inks between each print unit, whereas in offset printing drying between each unit is not normally necessary (wet on wet printing) but can improve overall drying – for example of black and dark color inks in UV printing.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.