Mondi and ATS-Tanner launch paper band for food bundles and multipacks

Kraft paper bundle packaging features functional barrier on both sides of the paper

Mondi and ATS-Tanner launch paper band for food bundles and multipacks

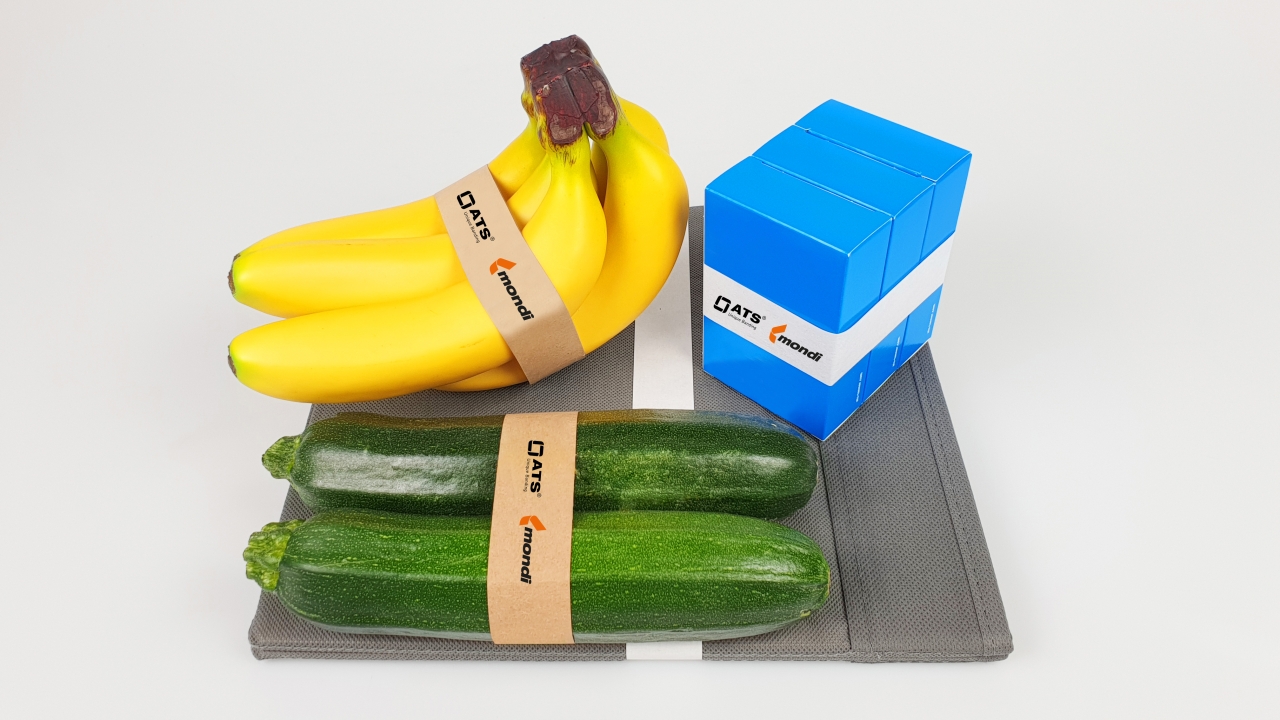

Mondi, a global leader in sustainable packaging and paper, has collaborated with Swiss converter ATS-Tanner to create TruePaper, a paper band, which can hold individually labelled products or bundles, reducing unnecessary plastic.

ATS-Tanner used Mondi’s kraft paper Advantage MF SpringPack and converted it into a band by adding a functional barrier on both sides of the paper. The paper is then sealed using ultrasound, eradicating the need for any adhesive. This ensures that the products are secured with minimum packaging, reducing waste and delivering a cost-efficient solution.

Mondi’s kraft paper can hold up to 20kg, making the band ideal for fruit and vegetable bundles as well as multipacks of bottles and other consumer goods. The paper ensures excellent printing results meaning brand, product, return and responsible waste management messaging can be communicated to the end user.

The paper band is made from renewable, responsibly sourced and certified materials. It is recyclable in existing paper recycling streams across Europe, even fulfilling Germany’s ratio of 95/5.

Carsten Breiter, Mondi, International key account manager, speciality kraft paper, said: ‘By combining our expertise in sustainable packaging with ATS-Tanner’s machinery and skills, we have created a system that offers great product protection while reducing unnecessary plastic.’

Serge Tanner, owner & CEO, ATS-Tanner said: ‘We trialled various paper grades and Mondi’s kraft paper offers the required strength to substitute plastic packaging with this paper band. TruePaper is a resource efficient product that can – depending on the banding machine used – wrap products measuring up to 1300 x 500 mm and is convenient to store. Using paper instead of plastic is not the only advantage: an ultrasonic banding machine from ATS-Tanner consumes 98% less energy than it would take to pack a like-sized delivery using a shrink-wrapping machine.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.