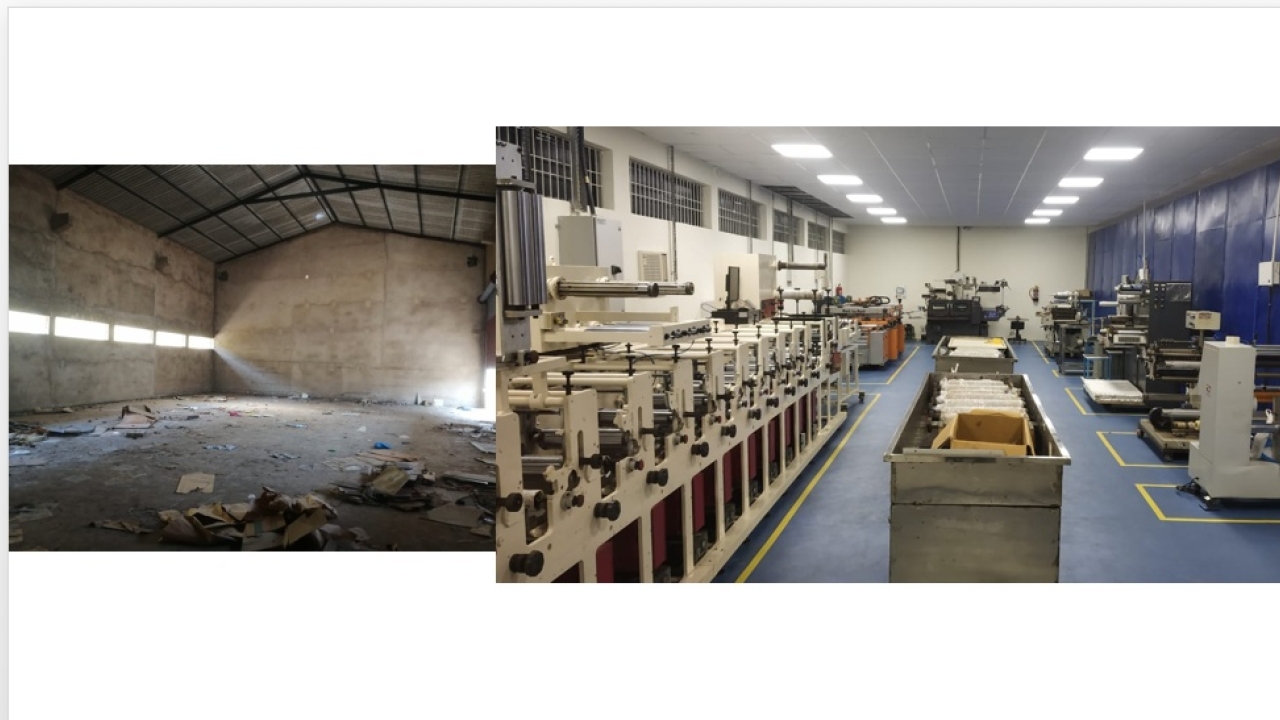

Kumar Labels opens Goa factory

The Indian converter had invested in a disused warehouse in early 2020 but the planning phase was interrupted by the lockdown. Undeterred, Anuj Bhargava, CEO of Kumar Labels, decided to press ahead. With the help of a contractor, they drew highly detailed plans of the layout, including specifics such as pneumatic and electric lines, water pipes, and other important aspects.

‘We didn’t have anyone to oversee the project. The contractors were local and we worked through video conferences. We gave them 3D views of each fixture and asked them to follow our measurements and execute our orders. They would call me five to six times a day for questions and procedures,’ says Bhargava.

The company has maintained the same look and feel in the new factory as its headquarters in Noida. ‘All our flooring material, ceilings, electrical fixtures, panels and other things were transported from the north to the west of the country in trucks. Due to a shortage of labor and the unavailability of forklifts at the time of lockdown, we sent the contractor trucks’ bed layout so they knew exactly how to unload material in a sequence and place them at the right spot without unnecessarily unpacking them. Each item was labeled with numbers and names and detailed installation instructions were sent. Each step was planned down to the tiniest detail so it got executed precisely. In the end, what matters is that it all worked,’ smiles Bhargava.

Despite the success, there were hiccups along the way. Bhargava did not consider the salty, sultry weather conditions of coastal Goa. ‘We sent galvanized iron pipes for water connections and plumbing, instead of using plastic pipes at the coast. Secondly, we realized strong air-conditioning was not required here. Thirdly, it rains so heavily that we had to build a shed to house the diesel generator so it can be switched on or off during heavy rains. Lastly, like any new set-up, we faced some human resource challenges with the local workforce which were ironed out with time and patience,’ he says.

Once the factory was set up, Kumar Labels sent a team of five people from its Noida plant to Goa to install presses and ancillary equipment, and to conduct trial runs.

The plant runs Kumar Labels’ first UV LED Multitec press, which was sent from its Noida factory, as well as new finishing equipment. ‘We saw companies working with 100 percent UV LED in China. There is no reason why we shouldn’t do it. UV LED enables fantastic running, fast drying that results in 25 percent better speed and 50 percent power saving. We are seeing results in Goa and are now in the process of switching to UV LED on our other presses in Noida,’ says Bhargava.

Virtual inauguration

Kumar Labels hosted a virtual inauguration of the new plant that was attended by customers. ‘We hosted a virtual plant tour and ribbon cutting by a customer,’ says Bhargava. ‘To ensure safety, the ribbon was tied on two wine bottles and cut at the customer’s house. He cut the ribbon during a video call and said “Start”, after which the press in Goa began running commercial production.’

The company is printing pressure-sensitive labels, cut-and-stack beer labels, pharma labels and shrink sleeves from this plant. ‘Our objective is to move closer to the customer to ensure shorter turnaround time and just-in-time delivery without any logistics issues. With a railway station and port close by, the location presents an opportunity to not only send labels around the country but also export to western Europe,’ explains Bhargava.

Bhargava has a vision of working on ‘hub and spoke’ model of running plants. While 2020 enabled the first step in this direction, next year will see Kumar Labels, which employs 130 staff across India, expanding with two smaller plants. ‘The factory in Greater Noida will remain the hub with labelstock and ancillary equipment manufacturing, research and development, as well as label printing. The new units will work in close contact with local customers and ensure quicker deliveries,’ he says.

‘I believe the current pandemic has done us good because it reinforced my vision that translated to a decision that we could execute. We saw a lot of new accounts that came to us because we could deliver. Being closer is a natural choice for customers.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.