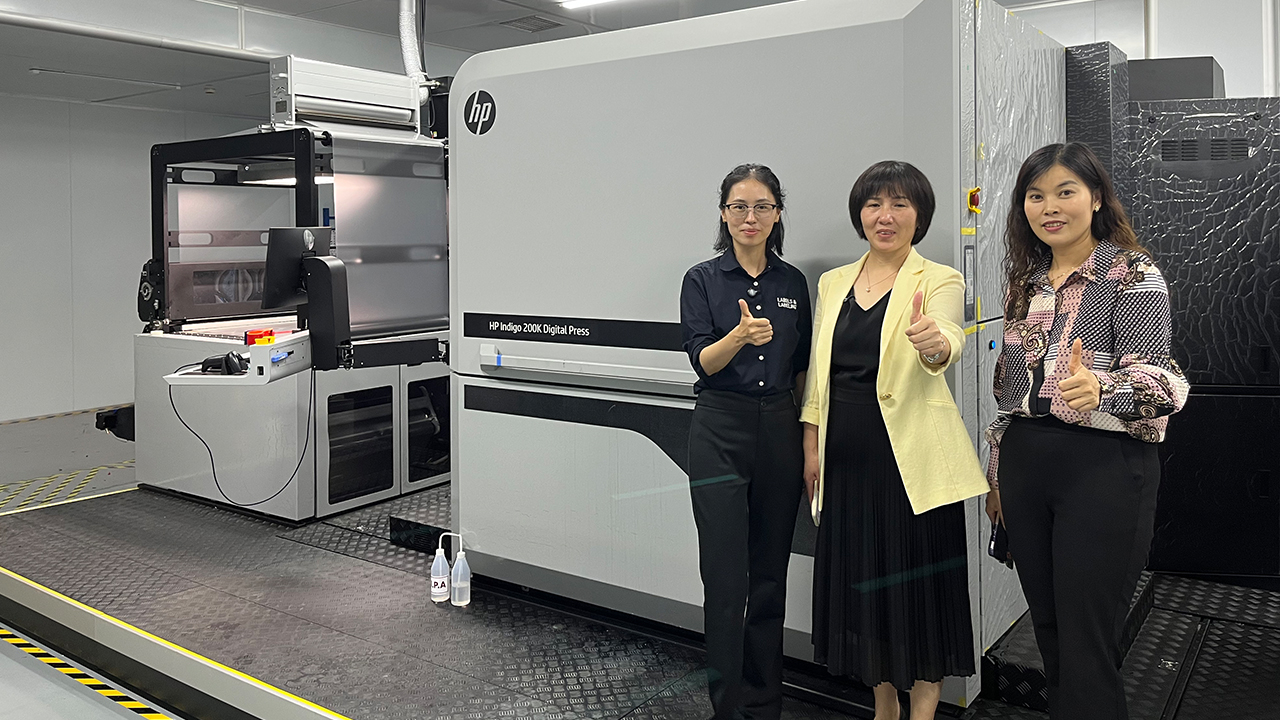

Honggan Packaging chooses HP for flex pack growth

Chinese converter has invested in an HP Indigo 200K and multiple pouch-making machines to drive growth in its short-run flexible packaging business

Honggan Packaging, a 27-year-old converter, has officially

embarked on its transformation from a traditional

packaging manufacturer to a digital service provider

with the installation of an HP Indigo digital press. The installation was HP’s 100th digital flexible packaging system in the Asia-Pacific region.

Founded in 2003 and based in Dongguan, Guangdong Province, Honggan Packaging specializes in the production of flexible packaging. It supplies a comprehensive range of plastic bags, aluminum foil bags, aluminum-coated bags and kraft paper bags. These offerings cater to domestic and international clients across various sectors, including food, electronics, apparel, cosmetics, pharmaceuticals, agricultural products and hardware.

In November 2024, the company relocated to its current facility, a 10,000sqm production space that houses its technology and a workforce of over 80 employees.

27-year history

Chen Weifeng, founder and general manager of Honggan

Packaging, stepped into the printed packaging business by chance. At that time, she received an order for plastic bags. The following year, a semi-automatic manual bag-making machine marked the start of her entrepreneurial journey. Subsequently, the company purchased second-hand film blowing equipment and began producing and selling single-layer plastic bags.

“HP Indigo’s 200K digital printing technology helps us transform from a packaging producer to a business that delivers a full digital experience for our customers”

As the business expanded, Weifeng relocated the company from Shenzhen to neighboring Dongguan in 2003, officially renaming it Dongguan Honggan Packaging. Later, the company shifted its focus to the composite plastic bag business and invested in gravure printing machines, laminating machines and pouch-making machines.

‘Back then, the entire flexible packaging industry was still a market dominated by large-volume orders, which was highly compatible with traditional printing equipment like gravure. Moreover, the profit margins were quite substantial, with such high demand,’ Weifeng continues.

Digital investment

As the number of competitors in the industry increased, overall profit margins shrank significantly. During this period, through interactions with customers, Weifeng identified new opportunities in the short-run flexible packaging market. Around seven years ago, the company began to pay attention to the development of digital flexible packaging printing technology.

‘At that time, we considered investing in a digital press,’ Weifeng says. ‘After research, we found that only HP digital machines were capable of printing flexible packaging. However, the cost of such equipment was prohibitive for us. Moreover, the short-run and small orders coming to our company were not sufficient to support an HP machine.' At that time, Honggan Packaging used industry suppliers to print its small-run orders.

Subsequently, Honggan Packaging invested in pouch-making

equipment for short-run flexible packaging. ‘Our plan is to invest in the whole production line from downstream to upstream,’ she explains. In 2024, the company invested in a digital embellishment machine from DMS, and in April 2025, Honggan invested in its first HP Indigo 200K.

To match the flexibility of this new digital press, Honggan Packaging has invested in four pouch-making machines. Now, digital accounts for half of Honggan Packaging’s total business.

Future outlook

In Weifeng’s opinion, overcoming industry competition should

never rely on price wars. Instead, Honggan Packaging has built its core competitiveness around ‘stable quality and fast delivery’.

The company has also established a 48-hour urgent order response service for digital businesses, specifically targeting small and medium-sized enterprises (SMEs) that seek to integrate agile packaging technology into their production workflows.

The company began expanding into overseas markets quite early on. At its peak, foreign trade accounted for as much as 80 percent of total business. In response to the 2025 China-US trade war, Honggan Packaging quickly adjusted its strategy. Currently, the proportion of foreign trade in its business stands at 60 percent. Over the next three to five years, Honggan plans to extend its digital printing capabilities to Southeast Asia and Eastern Europe.

Regarding immediate plans, Honggan Packaging has an ambitious digital transformation strategy for 2026, which includes acquiring a second HP digital press, implementing HP Smart Stream to automate the workflow from order placement to production, and adopting an AI-driven order scheduling system to enhance efficiency and reduce changeover time.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.