Screen opens European Inkjet Innovation Center

An impressive demo hall showcases Screen’s latest inkjet printing technology for the label, commercial and packaging markets.

Screen-Nilpeter hybrid press on the floor of the Inkjet Innovation Center

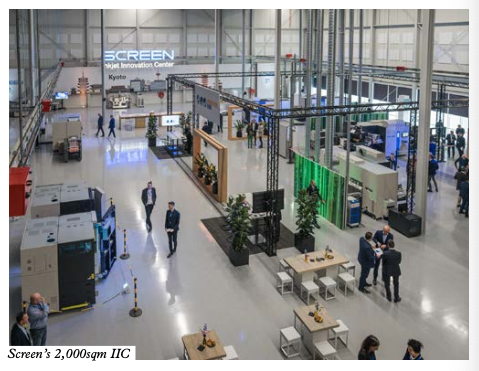

More than 100 customers, sales agents, supplier partners and local community representatives attended the opening of Screen Europe’s new Inkjet Innovation Center (IIC) in Aalsmeer, on the outskirts of Amsterdam.

In the impressive 2,000sqm showroom and demonstration center, visitors can explore Screen’s latest inkjet digital printing technology across three distinct product lines: Truepress JET for commercial printing and direct mail, Truepress Label for label printing, and the new Truepress PAC range for paper‐based flexible packaging. These presses are shown alongside Screen’s well‐ established CtP product range.

As well as a demo and applications center, the IIC will also serve as Screen Europe’s HQ and as a spare parts and servicing hub for Screen’s European customers, providing engineering support and preventive maintenance services as part of Screen’s 24/7 global support network.

‘Establishing the IIC reflects our confidence in the status of the printing industry and Screen’s position as a leading player in the market for inkjet digital printing equipment,’ says Eiji Kakiuchi, chairman Screen Holdings.

‘We overgrew our previous building due to our solid and steady growth in existing inkjet and CTP markets and also needed more space for the next wave of industrial inkjet digital innovations for both existing markets, such as label and commercial, as well as new markets such as flexible packaging.’

Osamu Yamagata, president Screen Europe, says the Inkjet Innovation Center will serve as a hub for innovations in digital printing.

‘Collaborating closely with our software and finishing partners, our aim is to provide customers with end‐to‐end printing solutions, offering a glimpse into the future of the printing industry,’ Yamagata says.

Among the VIP guests at the opening were AJ Kakiuchi, chairman of Screen Holdings, Yukiyoshi Tanaka, president Screen Graphic Solutions, and Takanori Kakita, advisor to Screen Graphic Solutions, alongside the Mayor of Aalsmeer, Gido Oude Kotte.

The ribbon‐cutting ceremony was accompanied by Japanese drummers marking the occasion with a thrilling performance of traditional Taiko drums.

Hybrid technology

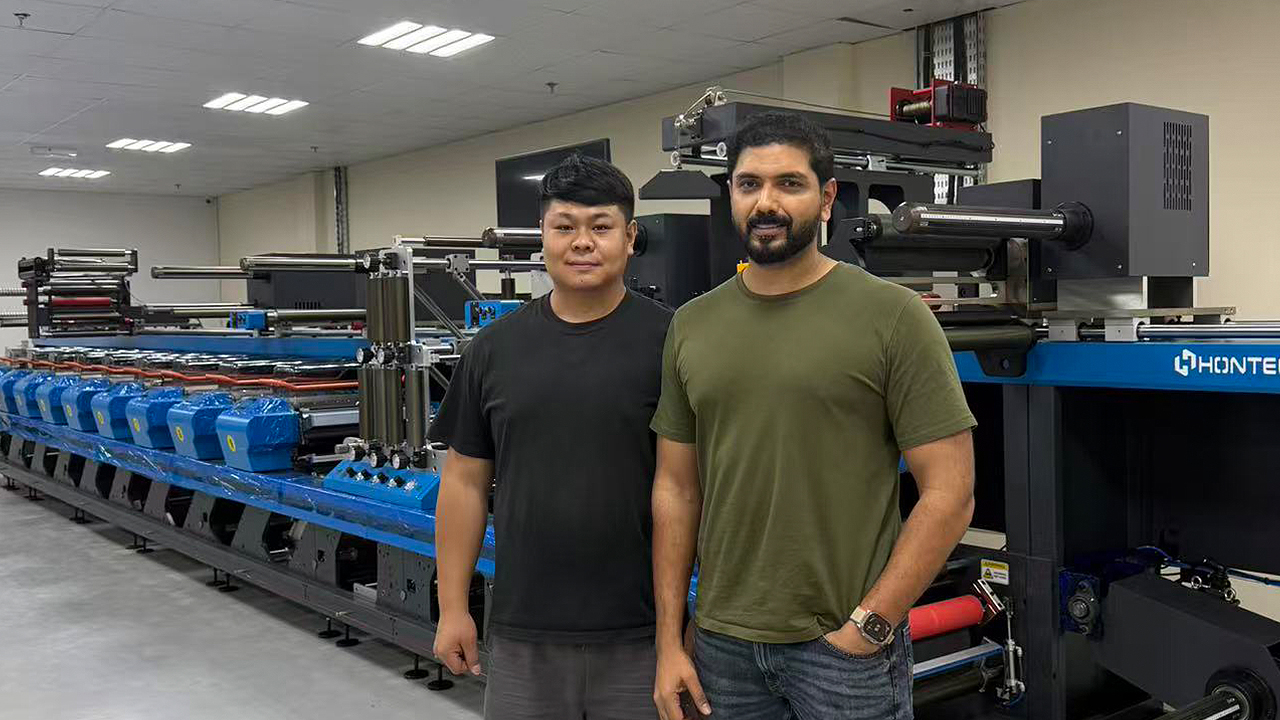

The demo floor showcases the latest Truepress Label Screen‐Nilpeter hybrid press, the third generation in the partnership between the two companies. This matches the new Truepress L350UV SAI‐S inkjet print engine with Nilpeter’s latest FA‐Line flexo press platform.

Soren Ringbo, general manager digital products at Nilpeter, manages the joint development program for Nilpeter.

‘This new press uses the most modern and automated version of the Nilpeter FA‐4 flexo press platform,’ Ringbo points out. ‘New features include individual digital touch panels on all print stations, part of the “Clean Hand” machine strategy to minimize operator’s direct intervention on the press. And you can now change a sleeve on the fly while the machine is running. This means the flexo unit can be more flexible in terms of a hybrid press, with faster setup and less waste. The FA‐4 control system has been expanded so it can exchange more messages with the SAI, making it easier to set up and run an embellishment process together with the digital print.’

Screen has also implemented a slow speed makeready mode which allows the FA‐4 units to register faster, producing less waste.

The SAI‐S print engine runs at 60m/min in CMYK+ blue, orange and white. The speed is expected to increase to 80m/min next year with new SAI model. The high opacity white option reduces print speed to 50m/min.

Primer station and new inks

At Labelexpo Europe 2023 Screen announced an in‐line digital primer for the Truepress L350UV SAI for substrates that exhibit poor ink adhesion or are very absorbent.

Ringbo is excited by the possibilities: ‘The inline primer is very useful. You only prime where you print, so you need less primer. And the primer will not affect the gloss of material surface as you only prime where it’s needed. Finally, it seems we have found a solution that will work for the wine market in inkjet. Because on many wine labels you don’t want the inks to be absorbed by the material, while you still want the matte surface remaining on the non‐printed area of the label.’

Screen also announced at Labelexpo Europe a new ink series that helps customers comply with the latest European safety regulations issued by the European Printing Ink Association (EuPIA). Screen’s new TPO/EDB‐free Truepress ink LV02 series for the Truepress Label 350UV SAI S print press complies with the EuPIA guidelines that were reclassified in April 2023, while offering improved lightfastness in yellow ink for more functionality.

In recent years, materials used in the packaging and label industries have been submitted to more and more scrutiny from a safety perspective. This has led to the reclassification of various substances as ‘substances of concern’.

Several types of printing inks were among these substances. UV inks, and in particular photoinitiators and monomers, are considered potentially harmful, especially compared to water‐based inks. EDB, a substance that is widely used as a photo‐ initiator in UV inks, was reclassified as H360. This means it is classified in the ‘reproductive toxicity’ category as defined in the European CLP Regulation.

In response to this reclassification, EuPIA has added EDB to its exclusion list. Another substance, TPO, was added to the REACH Substance of Very High Concern (SVHC) List, also due to reproductive toxicity concerns. TPO may soon also be reclassified by ECHA and included in the EuPIA Negative List in the same manner as EDB.

Flexible packaging

The second showroom press of interest to label and package printing converters is the Screen Truepress PAC520P water‐based inkjet press for printing on uncoated paper‐based packaging.

Juan Cano, business development director at Screen Europe, says: ‘Today under one percent of the flexible packaging market is digital, so we see great potential for ultra‐short runs, limited edition campaigns, personalization and production mock‐ups. Brands are making the move to paper from film pouches for reasons of sustainability.’

Cano sees the market for dry products as a key target for the PAC520P, and Screen showed some examples from Japan of a heat‐sealed paper pouch for chocolates. The food‐safe water‐based inks used in the press are formulated to be resistant to the high temperatures generated by heat sealing.

The press uses a heated cylinder to remove the water from the inks, meaning that, along with the natural absorption of the paper, no extended drying tunnels are required. This allows the press to occupy a very compact footprint. No primer or overprint varnish is required.

The PAC520P prints in four colors on a print width of 520mm at resolutions up to 600 x 900dpi, with a maximum reel diameter of 1350mm.

During its Labelexpo Europe 2023 press conference, Screen announced the launch of its TruePress PAC 830F, a water‐based inkjet press dedicated to printing on filmic flexible packaging. The company is expecting delivery of this sizeable machine to the IIC demo center over the next few months.

Click here to read more on Screen’s presence at Labelexpo Europe 2024.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.