Innovation on Tapp

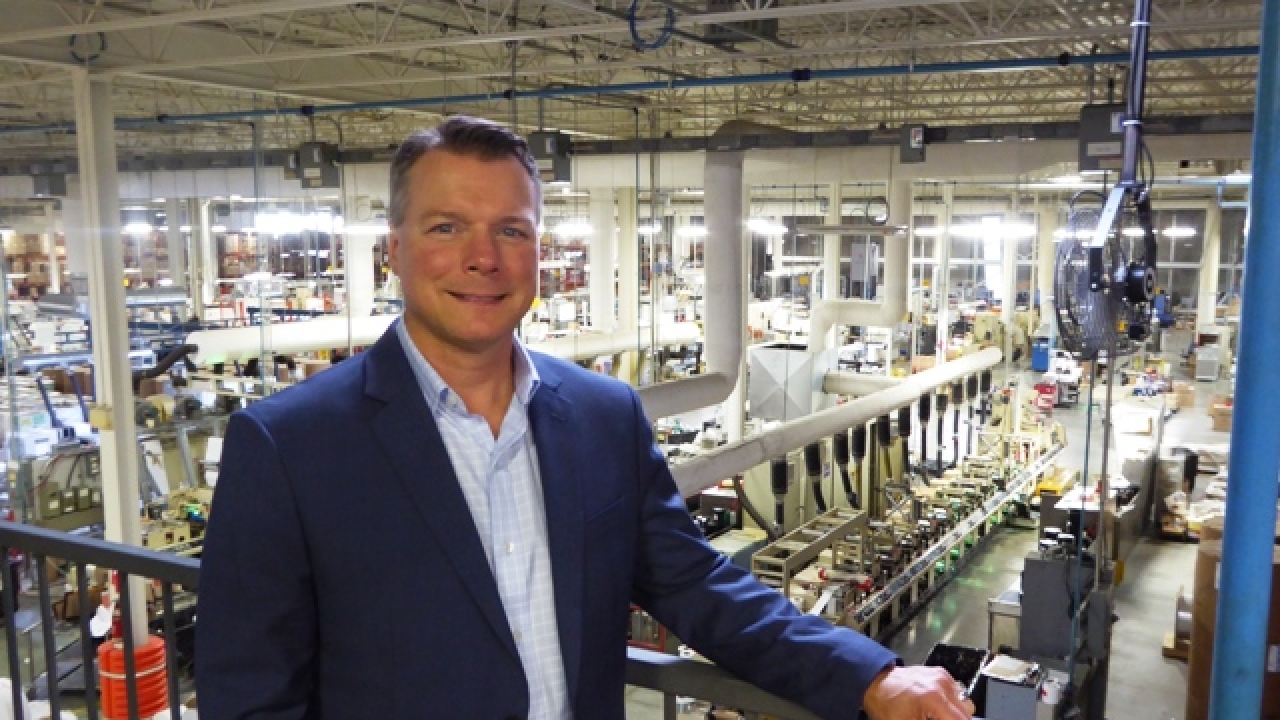

After a successful career at label companies including Vintage 99 Label, Staples Print Solutions, CCL and Cameo Crafts (a York Label company), Bowyer in 2014 acquired his first label converter under the name Tapp Label Acquisition Company. Working at lightning speed, he’s since acquired three more converters that together make Tapp Label one of the top 20 label converters in North America. Tapp Label has locations in California, Oregon, Vancouver and Toronto. The company specializes in high-end wine and beverage, beauty, food, pharmaceutical and more.

Acquisitions

In 2014 Bowyer acquired LabelOne Connect in Beaverton in Oregon and has since acquired three more label converters at a stunning pace. In the span of 12 months, Tapp Label acquired Bonham Label in Livermore, California, Tapp Label Technologies – which came with a facility in Vancouver – and Metro Label in Toronto, Canada.

‘I was able to get a lot done quite quickly,’ says Bowyer, speaking to L&L at Tapp Label Company’s Toronto-based facility. ‘It was a busy start-up as we rolled up four companies in our first year.’

And he’s not done yet. ‘I think we will continue to be competitive in the acquisition space,’ Bowyer enthuses. ‘We thrive on it, we love it.’

Since the acquisition blitz, Bowyer and the Tapp team have had their work cut out integrating operations across six facilities. It’s no small task to manage geographic diversification, and more than 200 employees between two US states, two countries and two Canadian provinces.

‘Integration has its challenges and it has its benefits. We’ve seen both,’ he says. ‘The biggest challenges are culture, and getting everyone on board with your systems. We’re big fans of outside consultants when it’s needed.’

Most recently Tapp Label Company invested 1.5 million USD to build a manufacturing facility in Paso Robles, California. News reports at the time acknowledge the strategy of expanding in the heart of California’s central coast wine country.

Bowyer said at the time of the 2015 expansion: ‘The central coast region remains an important and integral part of our label and shrink sleeve business in an expanding geographical area for the industry. Paso Robles will lend itself to ease of business with central coast high end wineries, breweries and distilleries, and position ourselves for growth.’

Tapp Label Company corporate offices are in St Helena, California.

Wine country

Being located in the heart of California’s wine country gives Bowyer close access to some of the nation’s premier wine companies. Because of this, more than one third of Tapp’s label work is from the wine industry.

Going forward, Tapp Label Company sees growth potential in shrink sleeves in addition to continued growth in the flexible packaging sector. ‘Sixty percent of our inquiries are for shrink sleeves,’ says Vinod Sharma, Tapp Label’s VP of sales.

Across its portfolio, Tapp Label has a mixture of printing equipment both conventional flexo, digital and offset machines. As well as equipment for shrink sleeve labels, where the company is looking to grow, Bowyer says he wants to look at flexo/digital hybrid presses at the upcoming Labelexpo Europe show.

Tapp has tapped into its customer’s desire for rapid turnaround time and created a unique partnership with Estée Lauder, by which the cosmetics company has a direct link to one of Tapp’s HP Indigo WS6800 digital presses dedicated to their jobs. That way, Estée Lauder can bypass pre-press and go straight to press for repeat jobs with multiple SKUs.

The Estée Lauder relationship is not the only area where Tapp innovates. Tapp believes innovation using the digital platform is the future of printing. Variable imaging, augmented reality, metallic inks and security inks are just some examples of what drives the market, according to Bowyer.

‘Tapp works in tandem with its partners on innovative projects such as textured surfaces on shrink sleeves, creating the feel of a golf ball or simulated leather are some of the many current trends in innovation,’ Bowyer says.

Additionally, its Toronto facility has been LEED-certified since 2005, and the heat generated from its presses is recycled through the HVAC and converted to heat the building.

Tapp Label Company serves customers in wine, spirits, cosmetics, health and beauty, industrial food and beverage industries. Its clients and the remaining business is a mix of industrial and food and beverage jobs. Clients are served throughout the USA, Canada, Central America and the Caribbean.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.