Converting heat shrink sleeve labels

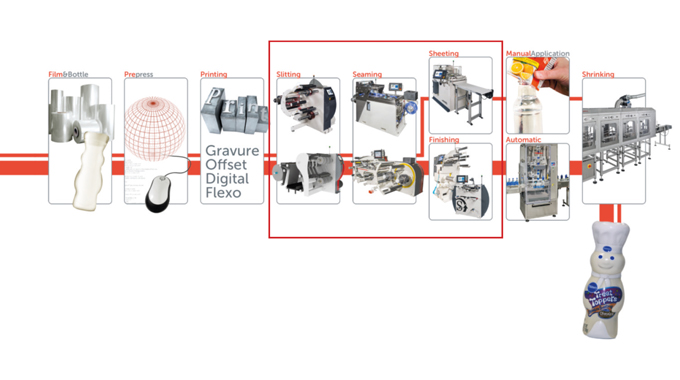

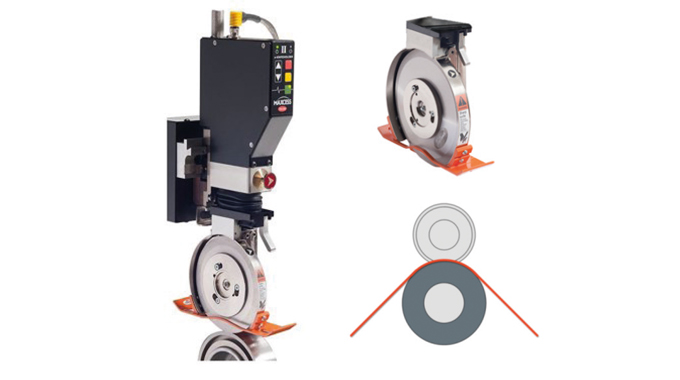

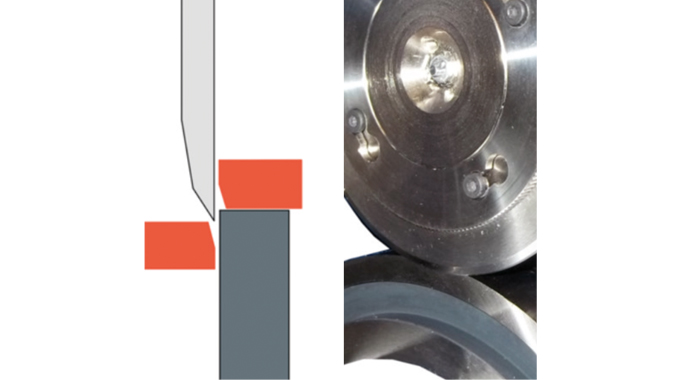

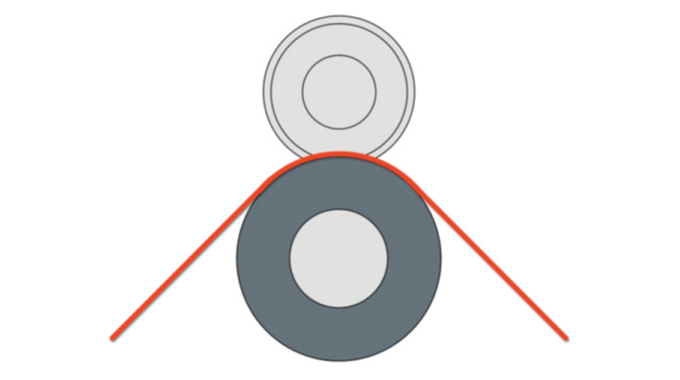

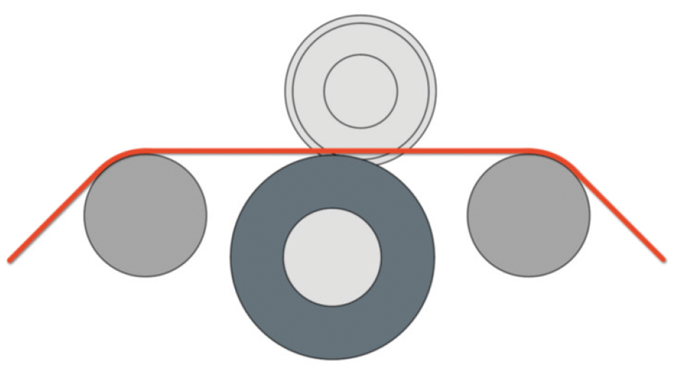

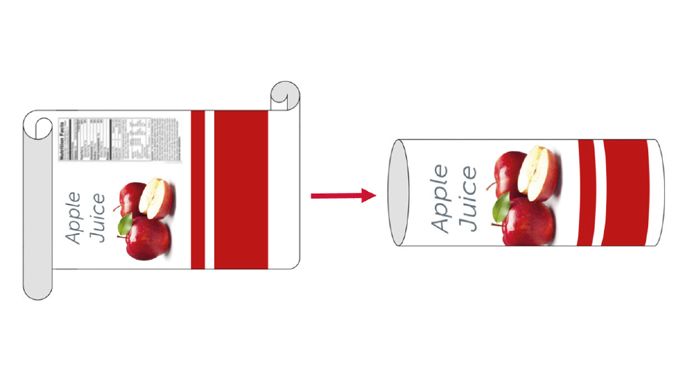

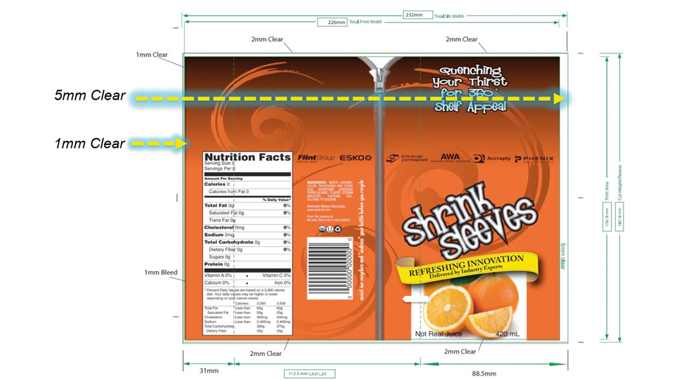

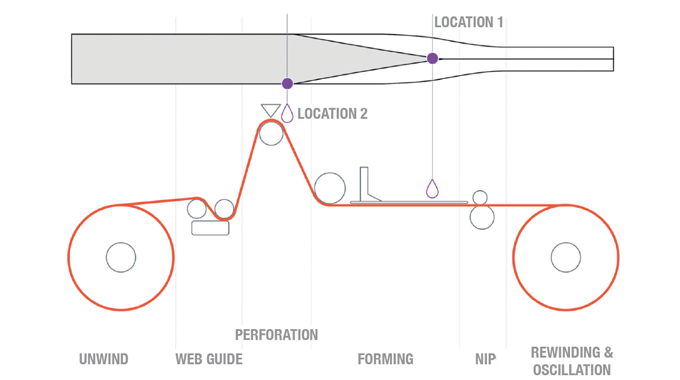

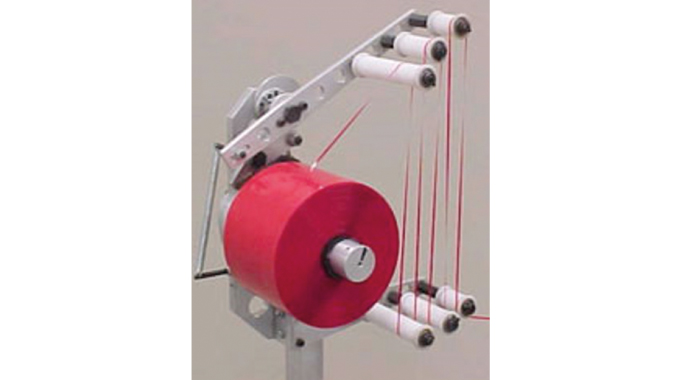

With film selection, pre-press and printing steps complete, we will now pick up the process with the next step, which is slitting (Figure 5.1, center). While slitting is not new to converters, what may be new is the extent to which slitting is critical to shrink sleeve converting. What makes it more critical for shrink sleeves is that the edges of the film have a newfound importance.

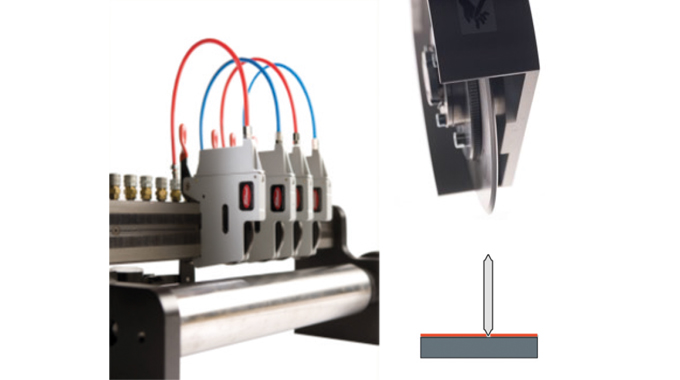

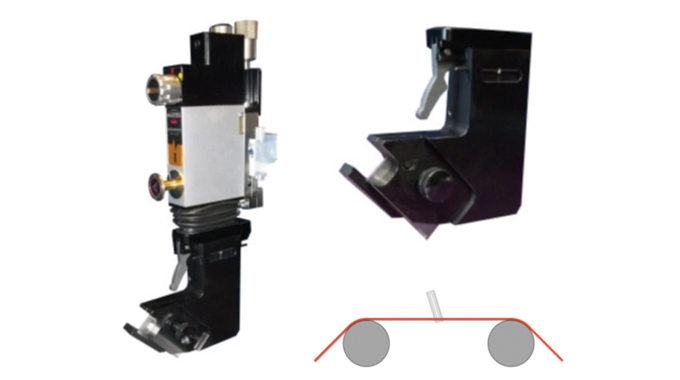

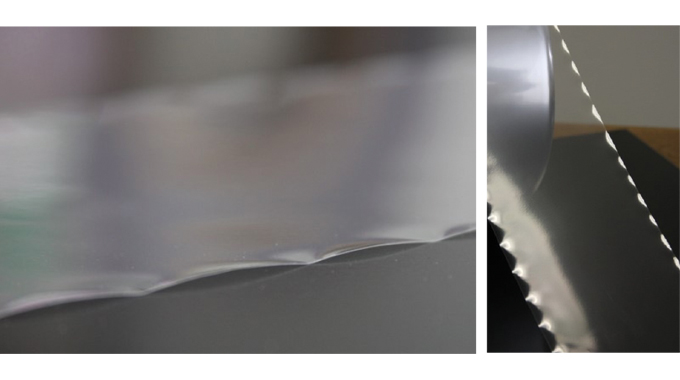

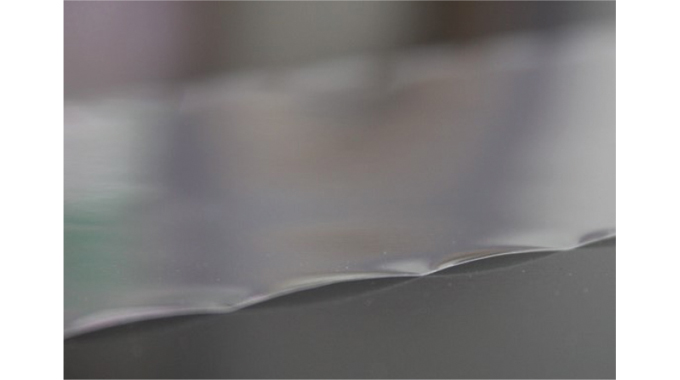

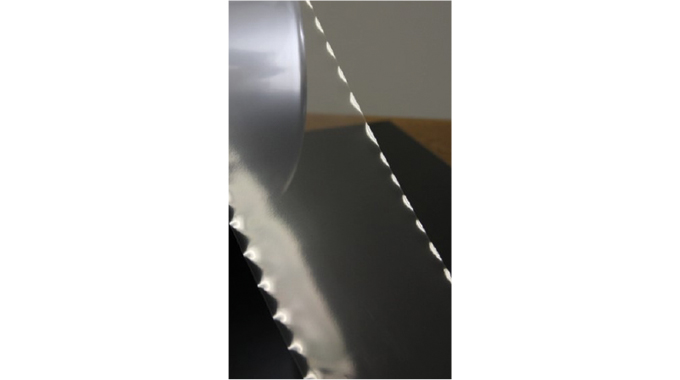

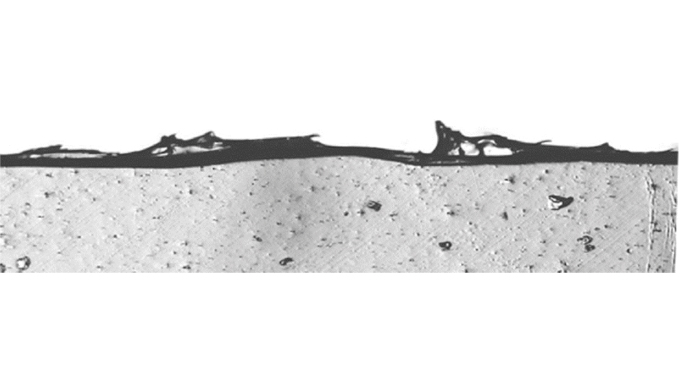

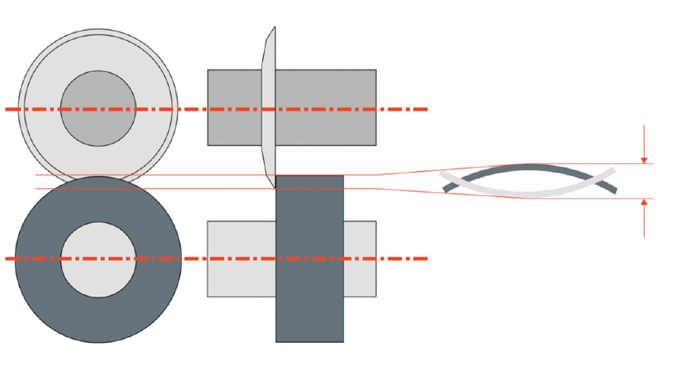

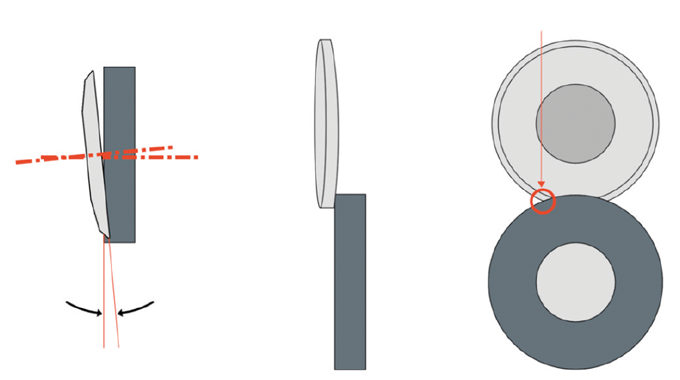

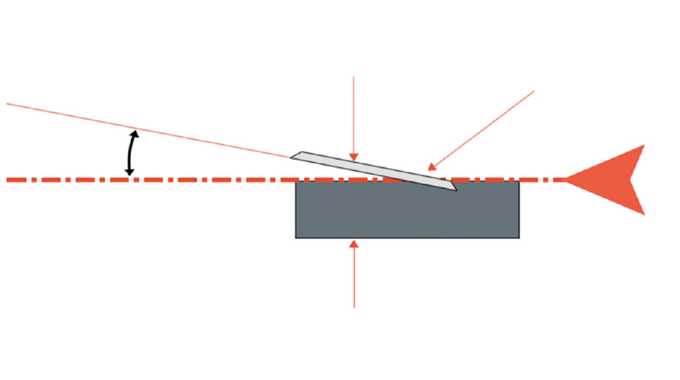

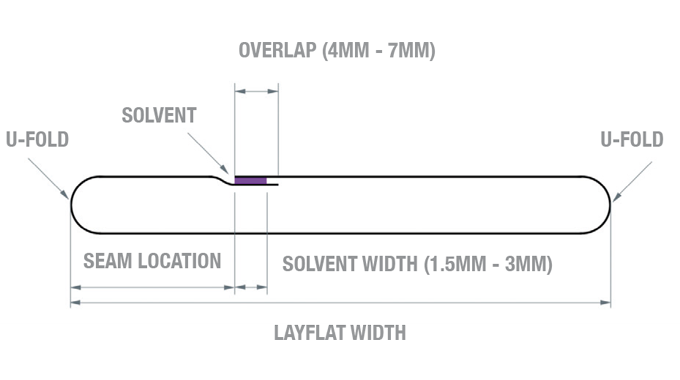

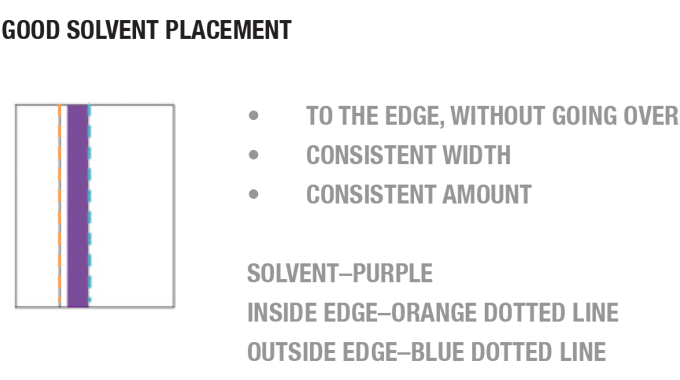

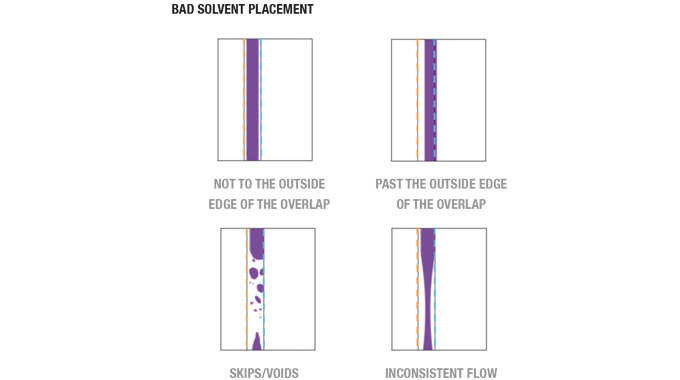

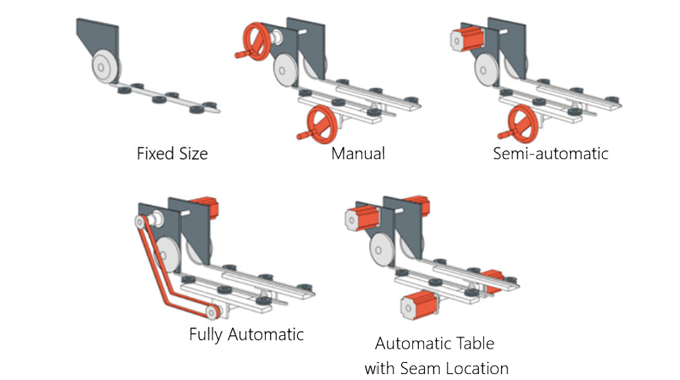

In no other slitting application are the slit edges of the rolls expected to be solvent-welded, which produces an overlapped seam that needs to be invisible on that finished product. While there is a range of slitting techniques deployed in the film converting market, several factors dictate that shrink sleeve labels be slit using tangential rotary shear technology, a concept that we will explain further in this article.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.