Efficient job planning and production scheduling

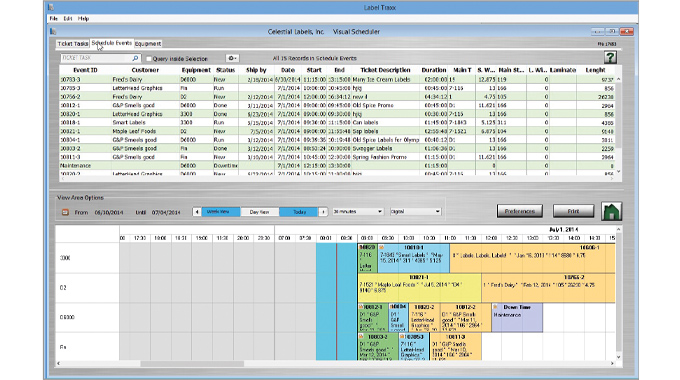

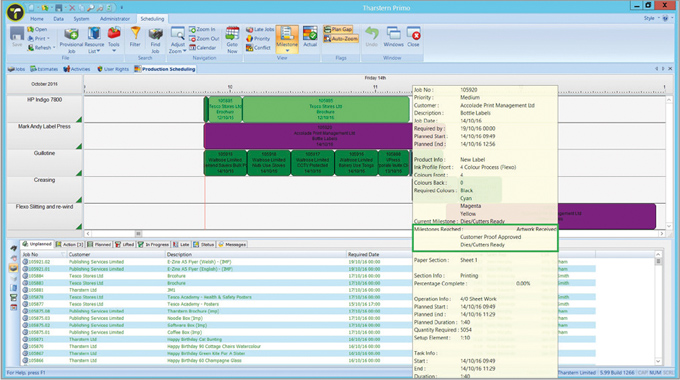

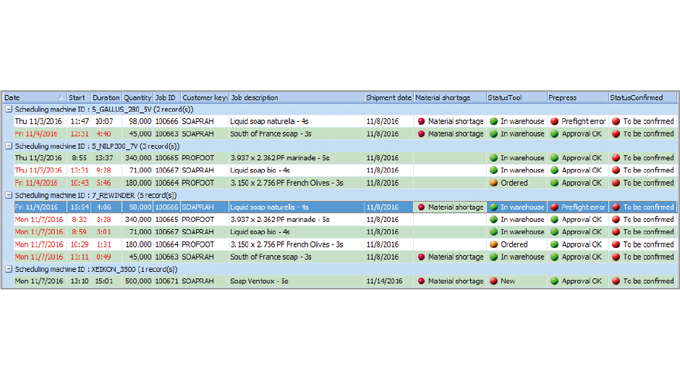

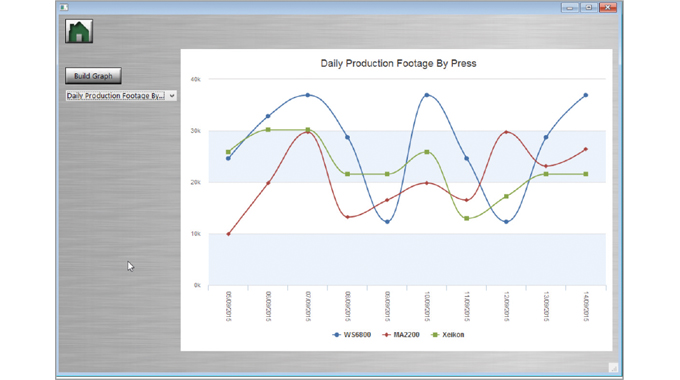

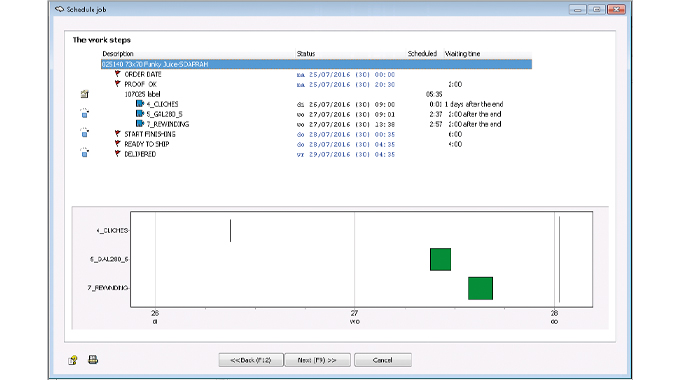

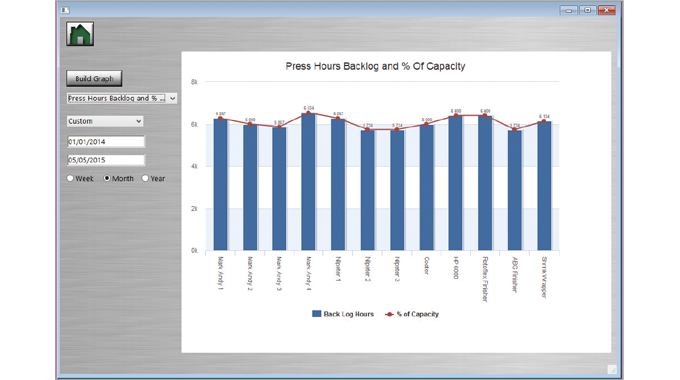

The process of planning jobs and managing their production through a label or package printing plant can be quite complex. The process need to constantly monitor the changing workload of individual machines and printing processes, complete print production orders to schedule, and maintain accurate staffing levels. Ideally it should also highlight spare capacity, display slippage, spot bottlenecks or problem areas, offer ‘what if’ scenarios and prioritize orders thereby maximizing the company’s technology investment and minimizing machine downtime.

The growing proliferation of shorter runs, the need for multiple versions or variations, a requirement for sequential coding or numbering, jobs with hot or cold foiling, embossing, matt or gloss varnishing, are just a few of the things that can challenge scheduling. Multi-shift and multi-process pressrooms present further challenges. Even pressrooms with just one or two presses and a handful of jobs at any given time, can make effective scheduling tricky.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.