FlexON’s bold leap into digital printing with Gallus One

From flexo specialists to digital innovators, the Czech converter demonstrates how a strategic investment in hybrid technology drives efficiency and growth in an evolving label market.

For a company that began as a small label specialist in 1994, FlexON’s transformation into one of the Czech Republic’s leading self-adhesive label manufacturers represents a compelling story of technological evolution and strategic investment. What began as a modest printing operation founded by two partners has grown into a 60-employee enterprise with a 3,000 sqm production facility on the outskirts of Prague, driven by a philosophy of continuous technological advancement and customer-focused service.

The company now serves a diverse client base across multiple industries, with approximately 85 percent of production serving the domestic Czech market and the remaining 15 percent exported throughout the European Union. FlexON’s emphasis on quality, speed and staying ahead of the technological curve has positioned the company as industry leaders in a competitive landscape where adaptability is increasingly essential to success.

“As a previous enemy of digital technology, if someone had told me that I would have two powerful digital machines by 2024, I wouldn’t have believed it”

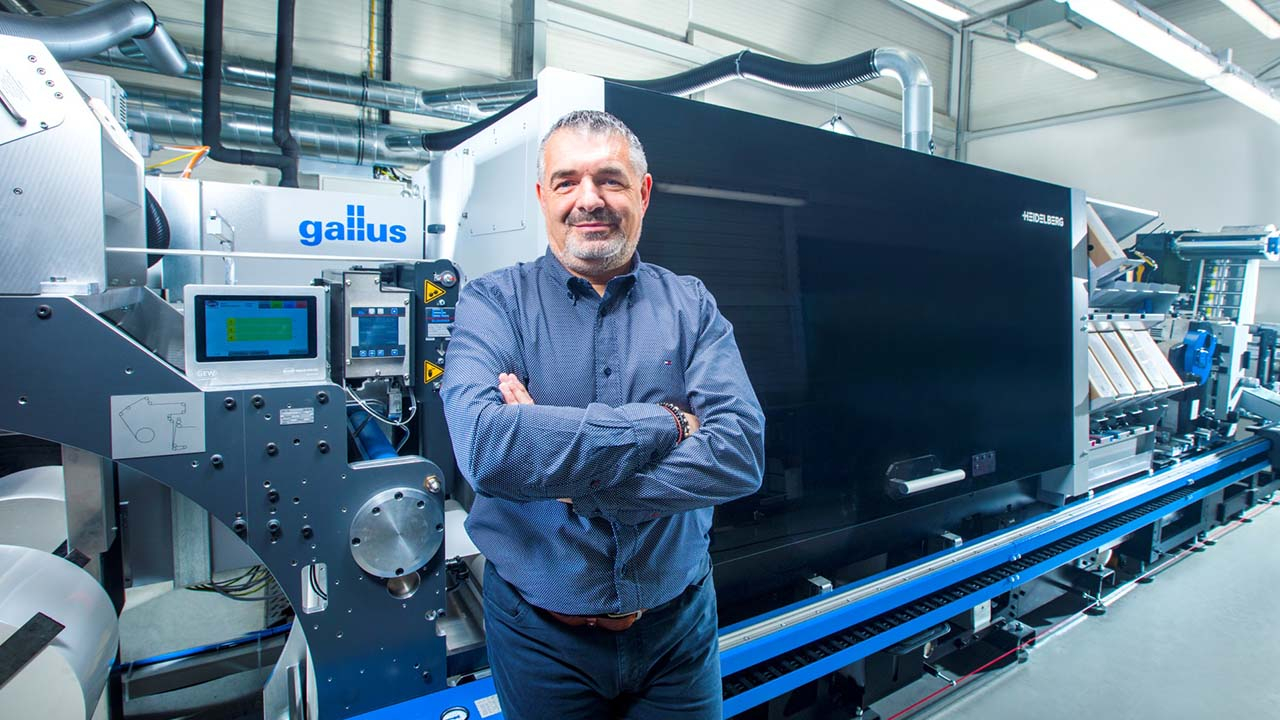

This commitment to innovation was further cemented in late 2024 with FlexON’s installation of a Gallus One digital press, a move that owner Martin Chaluš admits would have seemed unthinkable just a few years earlier.

‘As a previous enemy of digital technology, if someone had told me that I would have two powerful digital machines by 2024, I wouldn’t have believed it,’ he reflects. ‘But today, it’s clear that smart, connected printing is key.’

A history of firsts

FlexON’s relationship with Gallus stretches back many years. In 2008, it became the first in the country to install a Gallus RCS 330 press, setting a pattern for pioneering investments that would continue through the decades.

‘We’ve always believed in being early adopters of technology that can give us a competitive edge,’ Chaluš explains. ‘Being first means we can offer capabilities to our customers that others simply don’t have yet.’

The company’s growth trajectory has been closely tied to these strategic technological acquisitions. From its official establishment in 1994, FlexON expanded steadily, constructing its own production facilities in Vestec in 2003 and extending with another production hall in 2008, the same year it installed a Gallus RCS 330.

This expansion wasn’t merely about increasing square footage but creating a production environment optimized for efficiency and quality control. The company also obtained ISO 9001:2008 recertification in 2011, demonstrating its commitment to maintaining the highest standards of quality management throughout its growth phases.

The company’s willingness to embrace new technology reached another milestone in 2021 with the installation of a Gallus Labelfire 340, once again marking the first such installation in the Czech Republic. This hybrid digital press represented a significant shift in Chaluš’s thinking about digital printing technology.

‘Five years ago, I wouldn’t have bought this kind of machine, because at that time the quality wasn’t there yet,’ Chaluš says of the Gallus Labelfire. ‘Nonetheless, I went on, and now Gallus has digital machines where the quality meets the needs and demands of the market.’

The digital evolution continues

The successful integration of the Gallus Labelfire into FlexON’s production capabilities laid the groundwork for further digital expansion. By November 2024, the company was ready for its next significant investment: the installation of the Gallus One digital press, equipped with an additional flexo unit and a semi-rotary die-cutting module.

The Gallus One, launched in 2022, represents the latest in Gallus’s digital portfolio, featuring the System to Compose modularity concept. This approach allows converters to customize their press configuration based on specific market needs and production requirements. This level of flexibility aligns perfectly with FlexON’s diverse client base and varied label applications.

“We’ve always believed in being early adopters of technology that can give us a competitive edge. Being first means we can offer capabilities to our customers that others simply don’t have yet”

What makes this installation particularly notable is how quickly the press was put into production. According to Gallus Group, FlexON was printing customer jobs even during the operator training period, showcasing both the user-friendly nature of the technology and the company’s ability to rapidly adapt to new equipment.

‘The learning curve was surprisingly short,’ says Chaluš. ‘Our operators were already familiar with the Gallus ecosystem from our previous installations, which meant we could focus primarily on mastering the digital aspects rather than starting from scratch.’

For Chaluš, the decision to invest in the Gallus One was driven by evolving market demands. ‘Given increasingly shorter orders and frequent changes in artwork, the importance of digital printing is growing, which is why we looked at installing a digital label press,’ he explains. ‘We’re seeing average run lengths decrease year after year, while the frequency of design updates continues to increase, particularly in the food and beverage sectors, which make up a significant portion of our business.’

The press’s custom configuration, with an additional flexo unit and die-cutting capabilities, has created significant production efficiencies. ‘The custom composition of this new solution means that we now have a finished label that “falls out” of the press needing only to be cut, saving us time, streamlining production and increasing profitability,’ notes Chaluš.

The impact on FlexON’s production capacity has been immediate and substantial. ‘The Gallus One has now replaced up to two of our conventional presses,’ Chaluš reports, a testament to the productivity gains achieved through digital technology.

The Gallus partnership

FlexON’s choice of Gallus technology for its digital transformation wasn’t made lightly. When discussing the 2021 Gallus Labelfire investment, Chaluš highlighted several factors that guided his decision-making process, considerations that likely influenced the subsequent Gallus One investment as well.

‘From the practical viewpoint, in the first place, I wanted a machine with a big corporation behind it,’ he explains. ‘Another reason was our good relationship with the Gallus and Heidelberg suppliers, which provide us with first-class support and service. Moreover, our mutual relationship long ago grew from mere business to a friendship.’

The design and integrated nature of Gallus’s digital technology also played a key role. ‘I really liked the design of the Gallus Labelfire, the integrity of the whole solution. It’s actually a hybrid machine combined with other technologies,’ Chaluš noted. ‘It’s great that just one printer can run the whole unit, and at the end comes a finished product, including refinements.’

These advantages appear to have carried through to the experience with the Gallus One. Dario Urbinati, CEO of Gallus Group, comments: ‘FlexON is a dynamic and thriving business, and we look forward to partnering and supporting its activities over the coming months and years.’

The business case for digital

The rapid return on investment expected from the Gallus One installation highlights the business case for digital technology in today’s label market. Gallus reports that FlexON has ‘seen significant success within just a few months of installation, with the presses already demonstrating promise of achieving ROI and breakeven within an impressive timeframe.’

This experience mirrors that of other early Gallus One adopters. US-based PrintFlex reported that the technology had significantly reduced its production costs, with CEO Liz Pecha-Poelker describing the investment as offering ‘the lowest total cost of ownership for digital label production.’

For FlexON, conducting a thorough ROI analysis was essential before committing to such a significant investment. ‘We evaluated not just the upfront costs, but the total cost of ownership including consumables, maintenance and labor,’ Chaluš notes. ‘The calculations showed that for our specific mix of work, the Gallus One would provide substantial cost advantages compared to our conventional presses for runs under certain lengths.’

The advantages of digital printing extend beyond simple productivity gains. When discussing its earlier Gallus Labelfire installation, Chaluš emphasized the benefits of very short preparation times compared to conventional presses: ‘On conventional machines, preparation often takes much longer than printing itself. Preparing complex orders on the Gallus Labelfire takes about 10 minutes, and then you’re producing.’

He also noted particular advantages for orders with variable content but the same parameters: ‘This might involve labels in more than one language or labels where only the graphic varies. For Gallus Labelfire, these variations are one order with one preparation process. Then, the time savings are enormous. Not to mention savings on printing forms and start-up material.’

The elimination of printing plates represents a significant cost reduction, especially as material costs continue to rise across the industry. ‘Previously, we would need to create new plates for every design variation or color change,’ Chaluš explains. ‘With digital, those ongoing costs are eliminated, making even very short runs economically viable for both us and our customers.’

These same advantages apply to the Gallus One, with its digital workflow and rapid changeover capabilities, which are perfectly suited to the trend toward shorter run lengths and more frequent design changes that Chaluš has observed in the market.

A balanced approach

Despite its embrace of digital technology, FlexON maintains a balanced approach to its production capabilities. The company still operates both flexo and offset printing equipment, allowing it to match the production method to the specific requirements of each job.

‘Different technologies have different sweet spots,’ Chaluš explains. ‘For very long runs with minimal variations, flexo still makes economic sense. For mid-range runs with multiple variations or frequent design changes, digital becomes the clear choice. By maintaining capabilities across technologies, we can always choose the most efficient production method for each job.’

This philosophy echoes Chaluš’s current view of the industry: ‘Anyone who wants to stay in the market will need an appropriate combination of both digital and conventional technologies; it’s just a matter of proportion.’

“Anyone who wants to stay in the market will need an appropriate combination of both digital and conventional technologies; it’s just a matter of proportion”

This balanced approach also extends to its finishing capabilities. The Gallus One installation, with its integrated die-cutting module, allows for a finished product directly off the press, while still maintaining flexibility for more complex finishing operations when required.

The company’s production mix has evolved significantly since its founding. Where once long-run flexo jobs dominated its production schedule, today’s order board includes a much higher percentage of short to medium runs with faster turnaround requirements. The label market in the Czech Republic has followed global trends toward greater product personalization, regional variations and seasonal promotions, all of which favor digital production methods.

‘Today’s brand owners want flexibility,’ notes Chaluš. ‘They might need 10,000 labels today, then a quick revision for a product launch next week. Our conventional equipment simply couldn’t keep pace with these changing demands without significant cost implications. The Gallus One helps us say “yes” to these requests while maintaining healthy margins.’

Looking forward

With the Gallus One now fully operational, FlexON appears well-positioned for continued growth in the competitive Czech label market. The company’s history of technological leadership, coupled with its strategic approach to digital integration, suggests it will continue to evolve in response to changing market demands.

‘We are delighted to report the success of Gallus One customer in digital label printing: a powerful example of how our ongoing innovation efforts in this strategic growth segment are continuing to deliver transformative solutions to market and creating a meaningful real-world impact,’ comments Urbinati of Gallus Group.

The Gallus One technology itself continues to evolve, with Gallus showcasing an expanded version at drupa 2024 featuring a wider 430 mm print width and expanded color gamut for superior color fidelity. The company’s System to Compose modularity concept allows customers like FlexON to potentially upgrade and expand their press capabilities as new modules become available, future-proofing their investment against evolving market requirements.

For Chaluš and his team, the transformation from conventional print specialist to digital innovator represents not just a technological evolution but a fundamental shift in business strategy. Their willingness to embrace new technology, coupled with a practical approach to implementation, has positioned FlexON at the forefront of the Czech label industry.

‘The label industry never stands still,’ reflects Chaluš. ‘When we started in 1994, no one was talking about digital printing for labels. Now it’s becoming the dominant technology for many applications. Who knows what the next major technological shift will be? What I do know is that by maintaining our philosophy of quality, speed and technological progress, we’ll be ready to embrace whatever comes next.’

FlexON’s evolution mirrors broader industry trends toward more automated, connected and flexible production systems. The company has gradually shifted from being primarily a manufacturing operation to becoming a solutions provider, helping brand owners navigate the increasingly complex world of packaging decoration with expertise that spans both conventional and digital technologies.

As the label market continues to evolve toward shorter runs, faster turnaround times and more complex designs, FlexON’s investments in digital technology, particularly the Gallus One, appear well-aligned with these trends. For a company that has built its reputation on being first to adopt new technologies in its market, the Gallus One installation represents not just another ‘first,’ but a strategic positioning for future success.

With sustainability becoming increasingly important to brand owners, the reduced waste and energy consumption of digital production may provide further advantages.

Though Chaluš doesn’t specifically mention environmental benefits in his assessment of the Gallus One, the elimination of plates, reduced make-ready waste and more efficient production processes all contribute to a smaller environmental footprint, another factor likely to drive continued digital adoption across the industry.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.