Schreiner ProTech develops a label for Kratos Industries

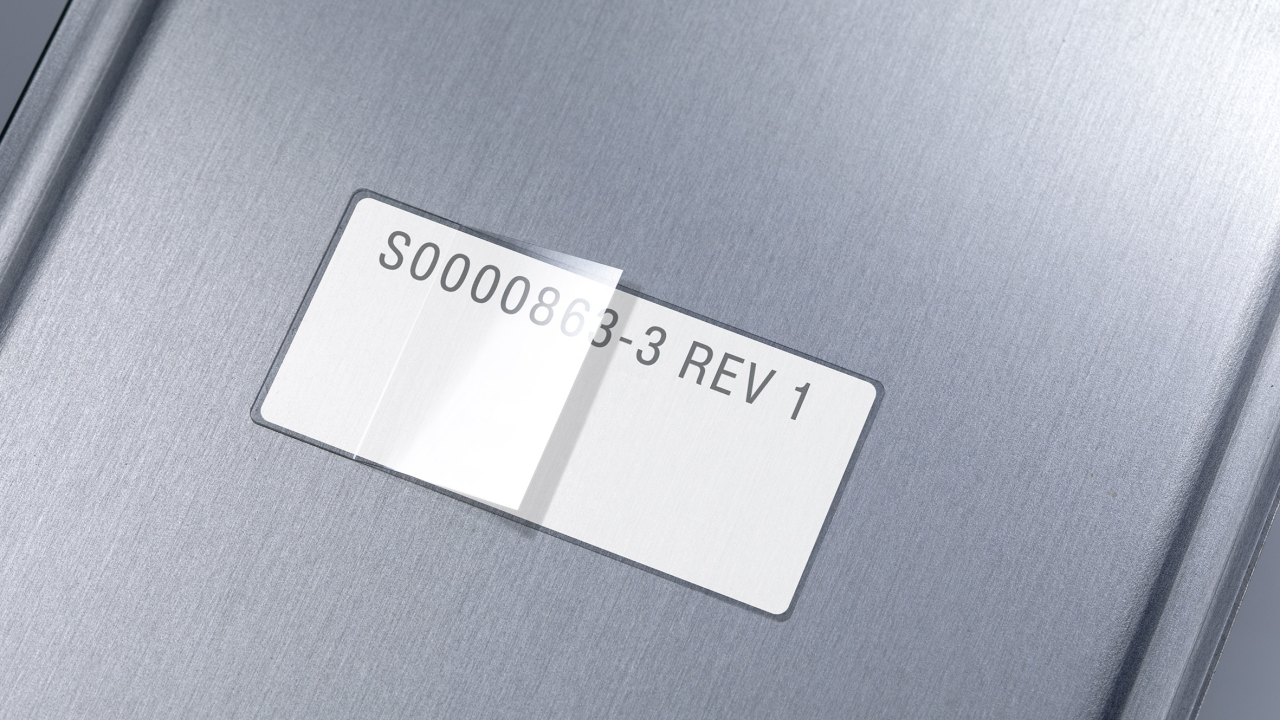

A paint-mask label was developed with Schreiner ProTech to ensure clear identification.

Kratos Industries in Colorado manufactures large control cabinets and has expanded over the last five years. Along with Kratos' business growth, the need for precision marking increased—an issue that posed a challenge for the company.

Kratos initially used simple cardboard nameplates, but they were error-prone. Initial tests with labels also failed because the paint-mask labels were difficult to remove after the paint shop. At the same time, the manufacturing process required equipment that combined strength with flexibility.

Supported by Schreiner ProTech in Blauvelt, the manufacturing engineering team at Kratos developed a method to peel the paint-mask labels immediately after the paint shop, while the components are still warm. That detail proved to be decisive. The labels can be removed without leaving any residue, improving identification and enhancing both inventory transparency and component allocation.

Robert Esquibel from Kratos Industries: 'For us, this and the collaboration with Schreiner ProTech is an important element in securing our growth on an organizational level as well.'

Doug Stubbs, sales account manager at Schreiner ProTech, added: 'In the end, it was truly a question of timing–in terms of removing the label and in terms of project work.'

The new marking enabled Kratos to support its expansion reliably. Central component identification and transparent allocation are key factors for future large-scale projects, and collaboration with Schreiner ProTech provides the basis for them.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.