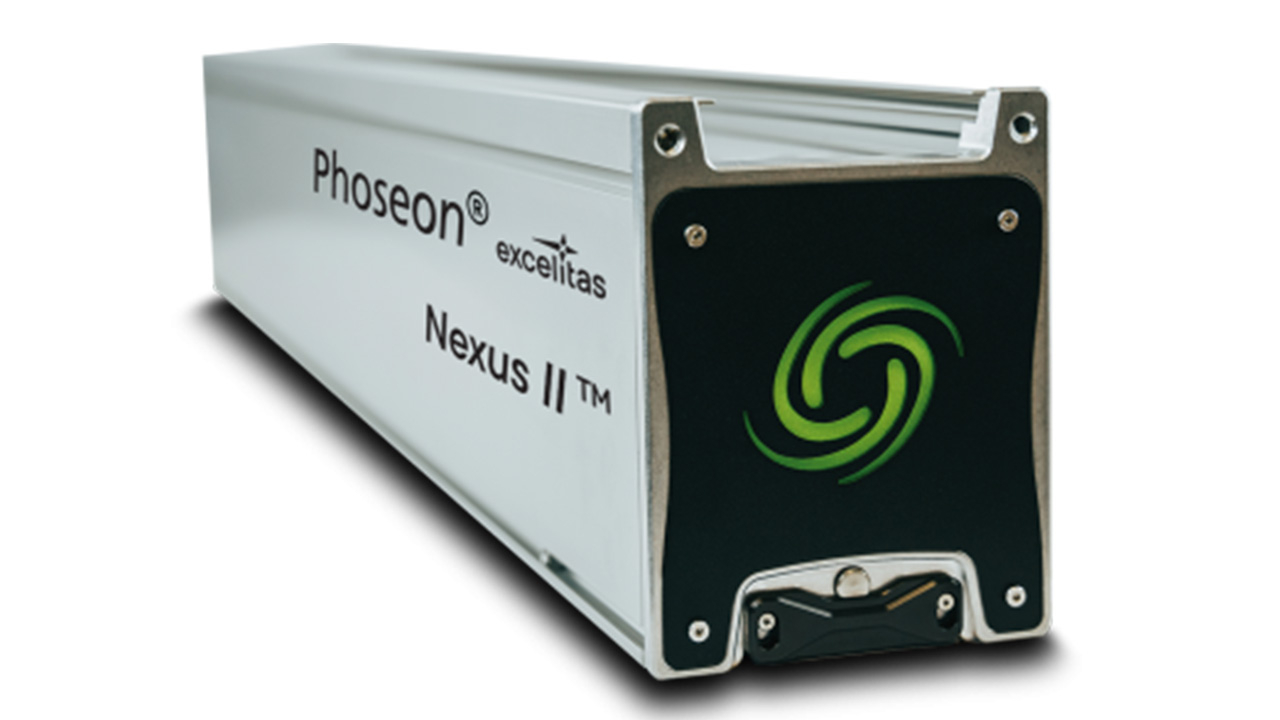

Excelitas introduces Phoseon Nexus II UV LED curing platform

The new system offers advanced monitoring capabilities and improved reliability.

Excelitas has launched the Phoseon Nexus II UV LED curing platform for flexographic printing, featuring increased system reliability, improved performance in high-temperature environments and an optional high-airflow model for enhanced cooling.

The system includes a new cloud-based monitoring technology, Nexus DataHub, which provides real-time and historical access to critical system data from any location. The monitoring platform tracks UV LED performance and overall machine performance to improve decision-making and operational efficiency.

Key features of the Nexus II include cloud-based access via a secure web portal or mobile app, real-time and historical monitoring with data intervals from 30 seconds to one hour, comprehensive data insights covering machine performance, UV intensity, system speed, and energy consumption, as well as 24/7 operation for complete system visibility.

The Nexus II UV LED curing systems deliver a high total UV power output to achieve increased print speeds, improved press uptime, and a longer lifetime. The platform comes with a five-year warranty for the entire system.

'Remote monitoring is a key component of Industry 4.0, enabling manufacturers to leverage data for improved decision-making and operational efficiency,' said the company in a statement.

Air- and water-cooled UV LED curing systems are available in sizes ranging from 300mm to 675mm. Nexus DataHub users receive special service and repair discounts.

Excelitas will display the Phoseon Nexus II platform at Labelexpo Europe booth 3B13 from September 16-19 in Barcelona.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.